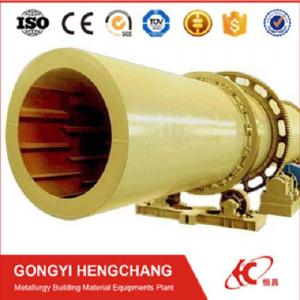

Three-layer rotary dryer is mainly used for drying granular material with humidity in certain range , and can be widely applied to various industries for drying slag, clay, coal, iron powder, mineral powder and other mixing materials, dry mortar and yellow sand of construction industry , as well as raw material of chemical and casting industry.

2. Working Principle of China Factory Price Small Three-Layer Rotary Dryer for Sale

The working principle of the machine is composed of three different diameters of concentric circles combined with each other, for the main body of the dryer, the entire body through the two ends of the wheel placed on both sides of the wheel, driven by two motor slow The drive is driven at both ends of the wheel, so that the cylinder can be uniform speed, smooth around its axis of rotation, the material from the inner tube into the tube, from the tube into the outer tube pushed to the discharge, due to the use of sleeve Type, the cylinder length is greatly shortened, with the same specifications of the single-cylinder dryer in the area compared to the area can be reduced by 50%, the sleeve structure to form their own insulation, work by the inner cylinder of the heat Tube absorption, the same token: the tube of heat from the outer cylinder of the material absorption, so that heat can be fully absorbed, thermal efficiency up to 80%, while the single cylinder dryer thermal efficiency of only 35%. Monolithic dryer due to the larger material travel, the cylinder heat loss is not effectively used, so the drying cost is higher, compared to: three drum dryer efficiency increased by 45%.

3. Main Features of China Factory Price Small Three-Layer Rotary Dryer for Sale

(1) high technical content, the cylinder self-insulation, thermal efficiency of up to 80% (single tube dryer thermal efficiency of only 35%), than the single tube drying 68% of coal, production increased by 100%.

(2) three drum dryer than the single-cylinder dryer machine length shortened by 60%, is conducive to the process layout. Reduce the building area of the plant, saving about 40% of investment. Covers an area of about 20m2.

(3) three barrel dryer using heat-resistant wear-resistant alloy steel plate, 4 times more than ordinary steel wear. Long service life, easy maintenance.

(4) three barrel dryer high thermal efficiency, the outer cylinder temperature below 60 ºC (single cylinder dryer outside the cylinder temperature up to 150 ºC), the outlet temperature is low, the discharge temperature is below 60 ºC.

(5) three barrel dryer export temperature is low, is conducive to the use of dust removal equipment for a long time, can be directly equipped with gas box pulse bag filter.

(6) civil construction investment reduced by about 50%, 60% lower power consumption.

(7) without the need for large gear rotation, the use of wheel rotation.

(8) three cylinder dryer hot air furnace can be supporting boiling furnace, coal stove, hand burner, also used in fuel, gas stove, can bake 20 mm below the block material, aggregates, powder material.

4.Our srrvice

(1) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client's factory.

(2)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3)Warranty:

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

5.our copmany

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments.

6.Technical Parameters of China Factory Price Small Three-Layer Rotary Dryer for Sale

Our factory produces different types of roller grinder and can be used to refer to the model you need based on the table data.

| Model | Outer cylinder dia(mm) | Outer cylinder Length(mm) | Cylinder volume(m*3) | rolate speed(r/min) | Max input temperature(c) | Capacity(t/h) | Power(Kw) |

| STH-2045 | Φ2000 | 4500 | 14.13 | 4-10 | 700-750 | 13-18 | 5.5*2 |

| STH-2250 | Φ2200 | 5000 | 18.99 | 4-10 | 700-750 | 15-28 | 7.5*2 |

| STH-2560 | Φ2500 | 6000 | 29.43 | 4-10 | 700-750 | 20-28 | 5.5*4 |

| STH-2765 | Φ2700 | 6500 | 37.39 | 4-10 | 700-750 | 24-33 | 7.5*4 |

| STH-3065 | Φ3000 | 6500 | 45.92 | 4-10 | 700-750 | 35-40 | 11*4 |

| STH-3270 | Φ3200 | 7000 | 56.27 | 4-10 | 700-750 | 40-60 | 15*4 |

| STH-3680 | Φ3600 | 8000 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5*4 |

| STH-4280 | Φ4200 | 8000 | 110.78 | 4-10 | 700-750 | 70-120 | 22*4 |

7. Buying Guides

To choose the appropriate model for you ,can you tell me:

(1) What's the raw materials(such as clay) and its size(mm/inch)?

(2). What do you neeed ?a machine or a dryer production line ?

(3). What's the required capacity(tons per hour or t/h)?

FAQ:

1 Are you a trading company or manufacturer? What is your main products?

We are a manufacturer, Our factory name is Gongyi Hengchang metallurgical building materials equipments plant. which has over 25 years of experience in this industry. Our Main products are Jaw crusher,Impact crusher,Cone crusher,Hammer crusher,Vibration feeder,Vibration screen,sand/stone washing machine,ball mill,flotation machine,Disc pelletizer, concentrator,Rotary dryer,Conveyor machine ,Briquette machine , Mixer ,Roller grinder and so on,We produce products divided into Stone prodution line and Sand-making productiong line,

Magnetic separating process ,Flotation separating process ,Gravity separating process ,Coal and mineral powder briguetting .

2 Can I visit your factory and clients' workshop? How to get to your factory?

Yes, welcome to visit our factory anytime, we can also arrange your visit in our China clients' workshop.

For getting to our factory, you can get a flight to Zhengzhou Airport. It just takes about 2 hour from Zhengzhou Airport to our factory by car.

3 What is your guarantee time and aftersale service?

--Our guarantee time is 1 years.

--EEach order machine we provide installation drawing and operation manual. If needed, engineers can be sent to your factory for installation and commissioning, training.

--Any problem in operation or others about machines, we will give solution in 12-24hours.

4 What is your payment term?

We can accept various payment terms if it is convenient for you.

5 What is your delivery time?

machine leadtime is 7 working days in standard specification, 15~20 working days if customized.

Pls tell your questions,Hengchang factory team are happy to serve&ready to be your business partner! If you want to know more details, please contact Winni ! Your satisfaction is our greatest pursuit.

Contact: Winni

Website: http://www.hcmachinary.com

Mobile: 0086 371 86106152

Wtatapp: 0086 13384024464

China

China