1. The drying machine is suitable for drying the loose materials, such as: Powder, particle and slice shape without big particles.

2. Application in chemical industry, food industry, feed industry and other industries, such as: Starch factory, feed factory, meat processing factory, wine factory, beer factory and so on.

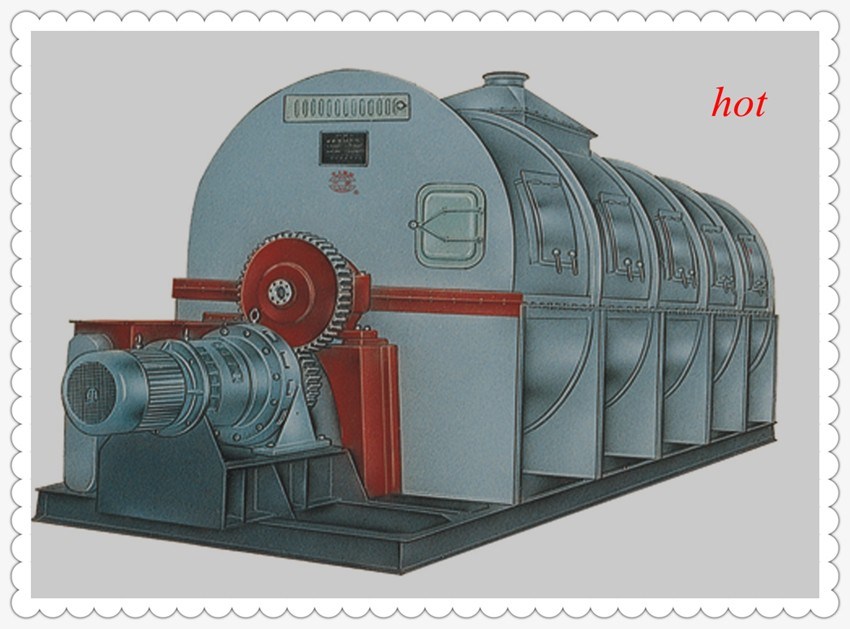

GZG pipe bundle drying machine is the indirect heated, contact type drying machine which can be both parallel flow and the counter-flow drying. Its major advantages are economic and practical. Among all kinds of the drying machines, it is the lowest in its power consumption and heat consumption. To evaporate one kg of water only consume 1.5 to 2 kg of steam, only 50% of the fluidizing dryer. To drying one ton of fermented grass powder consumes 15KW/H, only 25% compare to fluid-bed. Both the electric power consumption and the steam consumption reach the advanced level of the same kind products. The materials with high water content can be dried, the drying flexibility is wide. The drying time can be adjusted according to the materials property and moisture requirement. It can be continuous operation of high automation, or intermittent operation for special technical process. The machine has less accessories, parts occupy small area, has compact technical process and easy for installation.

| spec | speed of rotation (rpm) | main machine power (kw) | heat exchange area (m 2 ) | drying capacity (evaporate kg of water/m 2 h) | overall dimension (L*W*H)(mm) | weight (T) |

| GZG50 | 5-8 | 5.5 | 50 | 4.7 | 8032×1712×2250 | 9.0 |

| GZG100 | 5-8 | 7.5 | 100 | 4.7 | 9100×1912×2470 | 14.0 |

| GZG150 | 5-8 | 11 | 150 | 4.7 | 8500×2212×2810 | 18.5 |

| GZG200 | 5-8 | 11 | 200 | 4.7 | 10000×2212×2810 | 20.0 |

| GZG250 | 5-8 | 15 | 250 | 4.7 | 10200×2212×2810 | 23.0 |

| GZG300 | 5-8 | 22 | 300 | 4.7 | 10784×2488×3383 | 26.0 |

| GZG350 | 5-8 | 30 | 350 | 4.7 | 12048×2488×3383 | 28.0 |

| GZG400 | 5-8 | 30 | 400 | 4.7 | 13048×2488×3383 | 30.0 |

| GZG500 | 5-8 | 45 | 500 | 4.7 | 11298×2982×3965 | 40.0 |

| GZG600 | 5-8 | 75 | 600 | 4.7 | 12298×2982×4165 | 45.0 |

| GZG700 | 5-8 | 75 | 700 | 4.7 | 13298×2982×4365 | 51.0 |

China

China