DG Air stream Dryer for starch

DG series Air stream dryer is the drying plant for to dry maize, potato alike and other starch material processed by wet method after dewatering process. It's also for to dry heat sensitive powder or slice state material with fast speed.

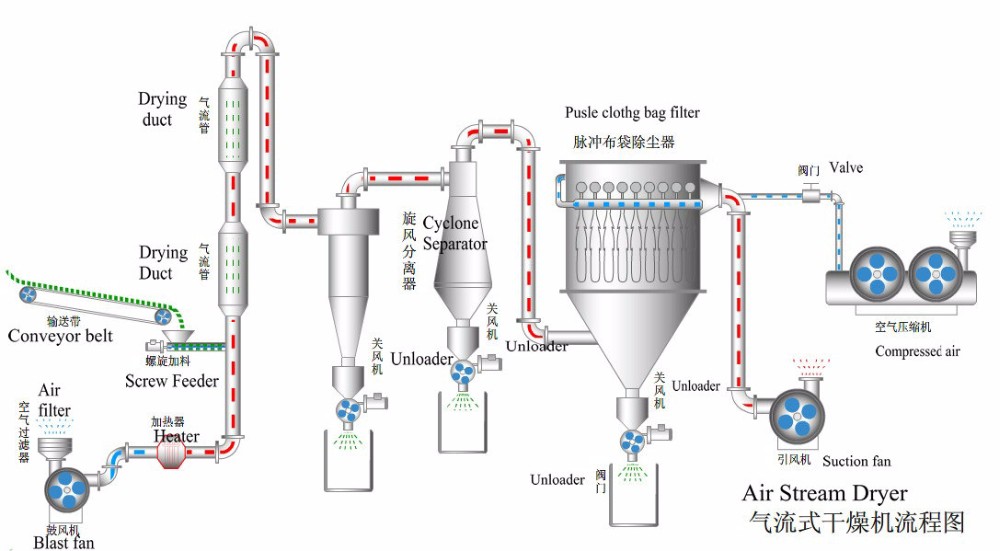

Wet material is dispersed into a stream of heated air (or gas) which conveys it through a drying duct. Using the heat from the air stream, the material dries as it is conveyed.Finished product collected is using cyclones, and/or bag filters. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements.

Principle

- In the dryer, high-speed hot air stream sustain raw material in the suspending state, then the material is dried. Since air stream speed is very high, and material is suspending in air stream, the heat transfer surface between air and solid is large, heat transfer rate is high, and drying time is short(usually within several seconds). It’s specially suitable for drying heat sensitive materials.

- In drying process, clean cool air is heated by air heater, and mixed with wet starch sent by spiral feeder and material raiser. Wet starch is dried momentarily. Dry starch is discharged though centrifuge separator and star shape.

Feature

1.This machine combines the whirl technology with the fluidity, ejection and smashing step technologies.

2. The equipment is compact and small in size, high in production efficiency and continuous in the production. It has realized that small equipment can perform the large production.

3. The drying capacity for this machine is big but its energy consumption is low. Its heat efficiency is high.

4. The material stay time is very short. The quality of the final products is very good. The machine can be used for drying the heat sensitive materials.

5. For the negative pressure or the micro-negative pressure operation, the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution.

6. High drying efficiency providing low energy costs

7. Continuous processing with short processing time

8. Low operator overheads and minimum maintenance costs

9. Controlled residence time enabling high temperature drying

Flow chart

Product parameters

spec | capacity of starch t/h | total power KW | steam consumption Kg/Kg water | finished starch moisture |

DG-0.5 | 0.5 |

| 1.8-2.0 | 12-14% |

DG-0.8 | 0.8 | 21.6 | 1.8-2.0 | 12-14% |

DG-1 | 1 | 24.6 | 1.8-2.0 | 12-14% |

DG-1.2 | 1.2 | 26.6 | 1.8-2.0 | 12-14% |

DG-1.6 | 1.6 | 30.1 | 1.8-2.0 | 12-14% |

DG-2 | 2 | 47.6 | 1.8-2.0 | 12-14% |

DG-2.6 | 2.6 | 59.5 | 1.8-2.0 | 12-14% |

DG-3.2 | 3.2 | 75 | 1.8-2.0 | 12-14% |

DG-3.6 | 3.6 | 95 | 1.8-2.0 | 12-14% |

DG-5 | 5 | 123.4 | 1.8-2.0 | 12-14% |

DG-6 | 6 | 170 | 1.8-2.0 | 12-14% |

DG-10 | 10 | 223.5 | 1.8-2.0 | 12-14% |

DG-20 | 20 | 440 | 1.8-2.0 | 12-14% |

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

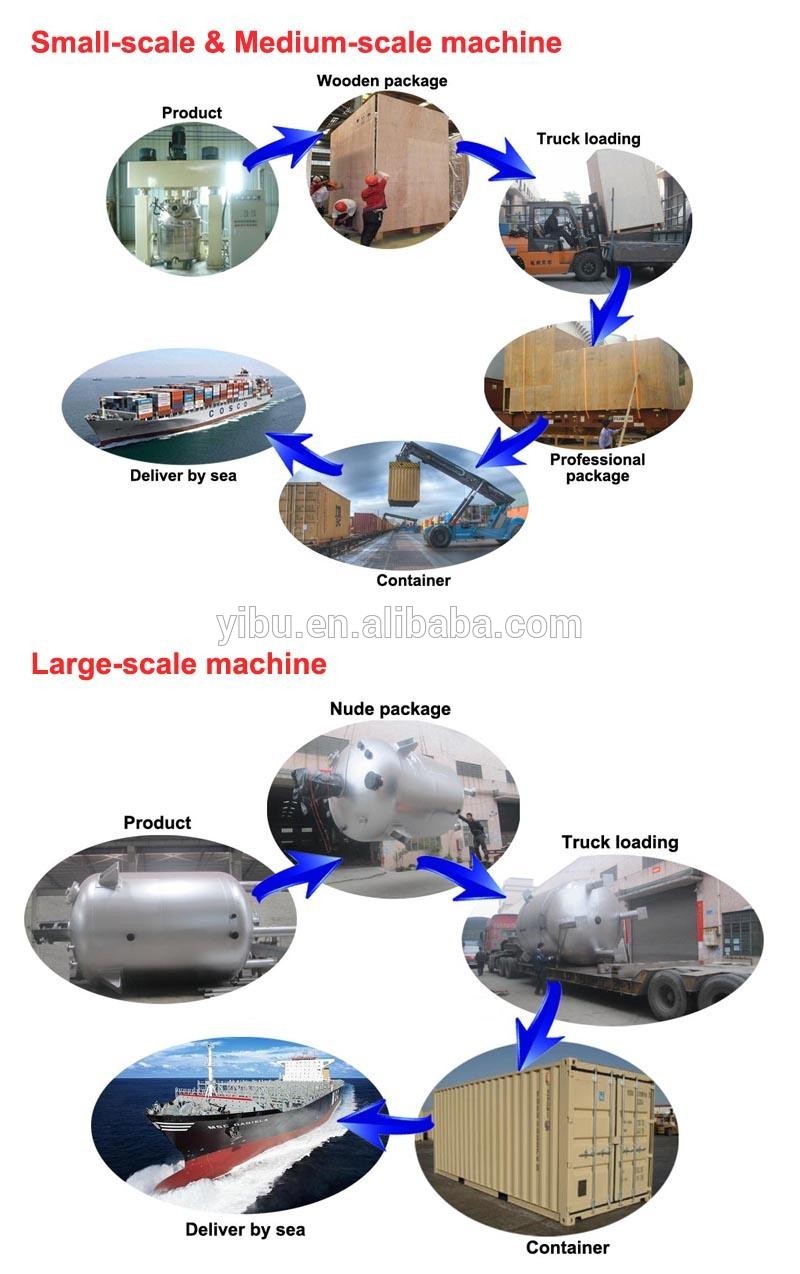

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

1.Are you a manufacturer ,trading company or a third party

We are a manufacturer ,and we have started our production on 1970 and have the private company right since 1995.

2.Where is your factory located?

Our company is located in Changzhou city ,Jiansu province,China .it is in the middle of Shanghai and nanjing .

3.How can I go to your factory ?

You can fly to shanghai pudong or hong qiao international airport directly ,and then take the high speed train or bus to Changzhou station and then we can pick you up at changzhou station for our company . Our company is around 30~40km away from the changzhou station.

If you are in China now , you can fly to benniu airport ,or take the train or bus to our city directly .

We sincerely welcome to visit our company at any time

4.What’s your mini order ?

Our mini order is one set .

5.Is there any certificate of YIBU ?

Yes, we got ISO9001:2008 Quality Management System Certificate,ISO14001:2004 Environmental Management System Certificate, OHSHS18001:2004 Occupatinal Healthe and Safety Management System Certificate, ISO10012:2003 Certificate for the system of Inspection measurement and Test, CE,SGS,TUV,GOST,UL,GMP,CCVO and so on . we have got 60 item patent for our equipment .

6.Is there any standard of electronic systems?

YES The electronic systems and their safety should comply with the requirements set forth in 21 CFR Part 11 and GMP Annex 11; The data should be collected at appropriate time intervals and stored in the system in a fixed format that can be printed out/read;

Access to all input and output values should be provided by entering the user personal code and password. The system should ensure three-level access (Administrator-Supervisor-Operator). A detailed description of the access rights for each level should be included to the equipment functional specification (FS);

7.Is the machine easy to performance update?

YES . YIBU adopt the modularity design technology .YIBU can improve the dryer performance to extend the dryer’s long time service. Our dryer is easy to disassemble ,clean and maintenance.

We are sure that our high quality products and excellent services will be appreciated by the growing list of satisfied customers. Contacting us is the first step to build a long and successful business relationship with us. Welcome!

China

China