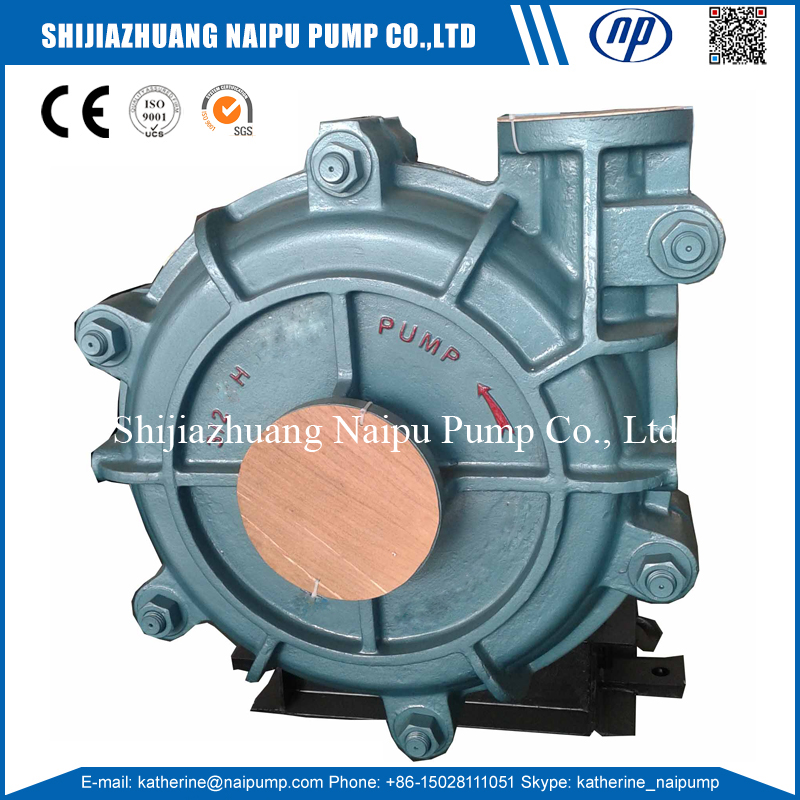

The M. AH. HH type slurry pumps are those of cantilever, horizontal and centrifugal ones, whose shafts can be sealed by packing seals or by centrifugal type seals. The positions of the pump outlet can be positioned at an interval of 45°according to different requirements, so eight different angles can be applied by rotation in installation.

The M. AH type slurry pumps have pump bodies (volute liners, front and back liners) that consist of replaceable wear-resistant metal liners or wear-resistant rubber liners, and impellers can also apply wear-resistant metal material or wear-resistant rubber material. The HH type slurry pumps only apply wear-resistant metal material as their pump bodies and impellers.

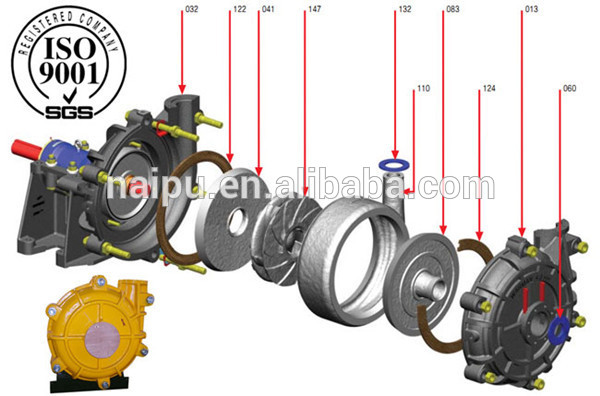

2. Structural Image:

HH-Series slurry pumps are suitable for severe slurry conditions with coarse particles and high competency.

2.1 There are two types of material for wet parts (volute liners, front and back liners, impellers):

l Made of high-chrome alloy material;

l Made of highly wear-resistant rubber material researched and developed by Naipu company.

Both of them can fulfill the task of slurry pumping with high efficiency and long service life.

2.2 Structure of shaft seals:

l Packing gland seals;

l Pressure-reducing metal gland seals;

l Pressure-reducing rubber gland seals;

l Mechanical seals.

HH Series slurry pumps have two kinds of structural modes, which are the high-chrome alloy one and the rubber wear-resistance one. The wet parts made of either alloy or rubber can be mixed up in operation.

For example: a rubber volute liner and liners can be combined with an alloy impeller in operation, and a rubber impeller can be used together wit an alloy volute liner and liners.

3. NP-HH SLURRY PUMP PERFORMANCE PARAMETERS

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | |||||

Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | NPSH/m | Nos of Vane | Impeller Diameter/mm | ||

1.5X1C-NP-HH | 30 | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

3X2D-NP-HH | 60 | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

4X3E-NP-HH | 120 | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 5 | 508 |

6X4F-NP-HH | 560 | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 |

8X6S-NP-HH | 560 | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 |

1. Slurry pump construction drawing

2. Main part number at the drawing

032: Frame Plate 041: Frame Plate Liner Insert 124: Volute Liner Seal 122: Stuffing Box Seal | 132: Discharge Joint 147: Impeller 083: Throatbush |

3. Materials of construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy | Chrome Alloy | SG Iron | SG Iron | Chrome Alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Rubber |

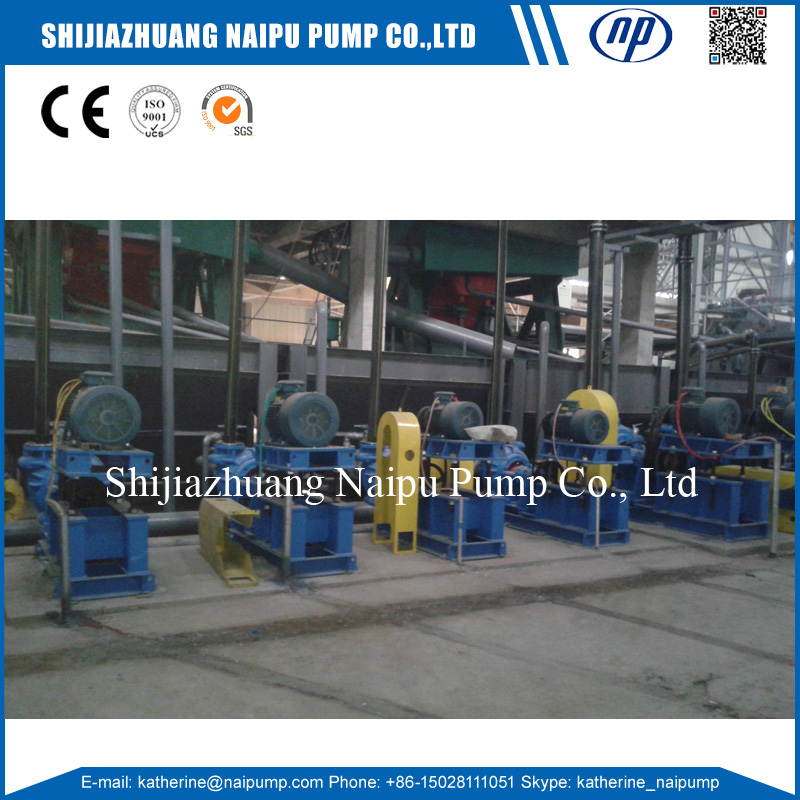

Naipu pump produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

Packaging details

1. Outside package: standard export wooden cases.

2. Inner package: Stretch film.

What service of Shijiazhuang Naipu?

| OEM service | Produce the pump and spare parts according to client's drawing or sample. |

| Pump slection | Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. |

| Using service | Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. |

| Quality control | Pay more attention to the quality in every process with different instruments. |

| Material service | Interchangeable metal design allow best material choice for any application. |

| After-sales service | Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. |

| Guarantee | One year guarantee for whole machine except of the wet end parts. |

Contact Person

Katherine Hou

CE, SGS, ISO9001 Certification

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps and spare parts. Which own Mould Workshop, Casting Workshp, Machining Workshop and Assembly Workshop.

China

China