The Inner thickness is 3.0mm, the exteral jacket thickness is 2.0mm, So our tanks have a good warm-keeping effect. Cylinder (Oval, SUS304), thickness: 3.0mm, Insulation layer: Rock wall-thickness: 80mm. Equipped with: Blender; Power: 1.5KW; Speed ratio: 1:43, Wort pipe and the washing pipe is separated device. Top manhole door: Diameter: 400mm, atmospheric pressure manhole design. Liquid level display device: sight glass & liquid level gauge, Equipped Sparging device for cleaning. Outsourcing surface: Weld polishing processing. As the polishing precision, it can up to Ra0.4µm. The surface is polished for 3 times.Cylinder (Oval, SUS304),thickness is 3.0mm. Insulation layer, Rock wall-thickness is 80mm.

Main Features

Effective volume:200L-10000L

Inner container: SUS304,Thickness 3mm, 2B finished.

Outer container: SUS304, thickness 2mm, Grind arenaceous.

Shell jacket: SUS304, thickness 1.5mm.

Insulation Material: polyurethane, thickness: 80mm.

Ribbon polished for the welded place.

Conical top/ Cylinder/ conical bottom/ shell jacket(one or two sections) / bottom jacket / insulation both on shell and bottom / with adjustable legs.

Connections:level interface/ steam Import and Export/ Pt100 interface/ top manhole / respirator/ Inlet/ Outlet.

| Capacity | Cylinder(ODxH) | OAH | Inner Thickness |

| 7BBL | 1000 x 1250mm | 2530mm | 3mm |

| 10BBL | 1150 x 1250mm | 2670mm | 3mm |

| 15BBL | 1250 x 1680mm | 3250mm | 3mm |

| 20BBL | 1400 x 1700mm | 3400mm | 3mm |

| 30BBL | 1650 x 1850mm | 3740mm | 3mm |

| 40BBL | 1750 x 2050mm | 4040mm | 3mm |

Fermenter system

Refrigerating System

Based on the absorption of the foreign technology and innovate, there are more than 20 invention patents. All the parts are made of stainless steel 304(pipeline and inside and outside of tanks are polished very well). In the production process, we will make a very strict inspection on welding. The quality of our products reaches the first class in China.

Inner (SUS304) thickness: 3.0mm,

External-jacket (SUS304) thickness: 2.0mm, Insulation: Polyurethane-thickness 80 mm,

Internal and external panel protection, weld slinging band; Valves, accessories supporting. Temperature mode: PT100 temperature probe, temperature transmitting, temperature control panel display.

Feeding method:

Ethylene glycol or alcohol water from the tank top manhole door an injection, refrigeration water since the ice water tank top into. Discharging method: Ethylene glycol water from ice water tank bottom ethylene glycol out pipe discharge, cooling water from ice water tank bottom cooling water return pipe out.

The refrigerating unit for water tank water cooling, through the cycle to fermentation tank cooling, through the plate heat exchanger to heat wort cooling.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| Packaging | |

| Size | According to requirement |

| Weight | 100KGS---5000KGS |

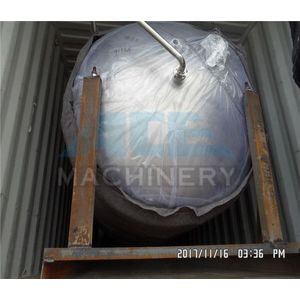

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tighter, we will use pe film for packing or pack it according to customers special request. |

| Loading | |

| Size | Customized the diameter to fit. |

| Weight | 100KGS---5000KGS |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Brewery house

88.8% Response Rate

Beer Fermentation Tank

98.8% Response Rate

1000L Fermenter

96.8% Response Rate

China

China