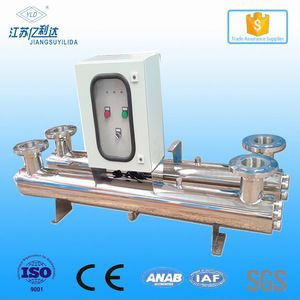

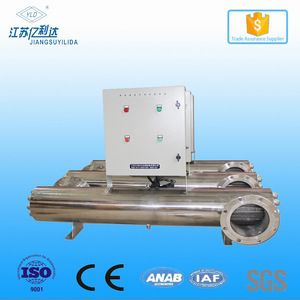

Small Flow Rate Water Disinfection Device 254nm UV light Sterilizer

Working principle

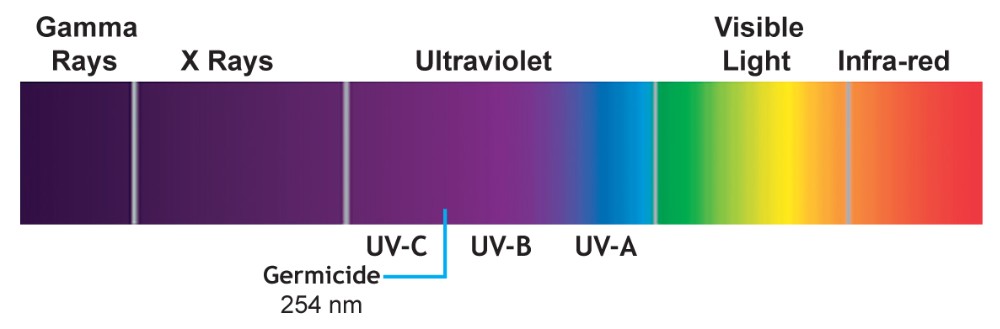

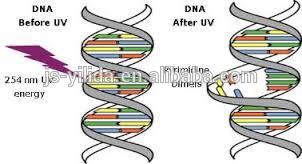

UV sterilization is actually a very simple process for inactivating unwanted free floating microscopic water borne bacteria, parasitic, fungal, viral, algae, and other unfriendly pathogens out of water by exposing it to high intensity ultra-violet (UV) light. UV radiation has three wavelength zones: UV-A,UV-B, and UV-C.UV light with wavelengths from 200-300 nm(UV-C) inactivates most microorganisms, with the greatest amount of inactivation occurring around 260 nm. A low-pressure mercury lamp resembling a fluorescent lamp produces the UV light in the range of 254 nanometers (nm). UV light has the ability to effect the function of living cells by altering the structure of the cells nuclear material, or DNA. The end result is the organisms die off, eradicating your water of these unwanted nuisances.

Using UV light in drinking water treatment requires the generation and application of UV light in a way to maximize its effectiveness. All UV drinking water treatment devices require power to generate UV light. When a UV lamp is turned on, mercury in the lamp is “excited” and takes on energy. The mercury quickly discharges that extra energy in the form of UV light.

However, the organisms must be free-floating and travel through the UV sterilizer unit for the sterilizer to work. It has no effect on organisms attached to fish or rocks because they do not flow through the unit and cannot be exposed to the UV light, pretreatment may need be added to the water system. Prefiltration is required to remove color, turbidity, and particles that shield microorganisms from the UV source. Water that contains high mineral can coat the lamp sleeve and reduce the treatment effectiveness. Therefore, pretreatment with a water softener or phosphate injection system may be necessary to prevent build-up of minerals on the lamp.

Water Quality (Feed in)

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels

Maximum Concentration Levels (Very Important)

Iron | ≤0.3ppm(0.3mg/L) |

Hardness | ≤7gpg(120mg/L) |

Turbidity | ≤1NTU |

Manganese | ≤0.05ppm(0.05mg/L) |

Tannins | ≤0.1ppm(0.3mg/L) |

UV Transmittance | ≥750‰ |

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added measures to improve water quality to treatable levels. If, for any reason, it is believed the UV transmission is not satisfactory, contact the factory.

UV wavelength (nm)

DOSAGE is the product of intensity & time dosage=intensity*time=micro watt/cm2*time=microwatt-seconds per square centimeter (μW-s/cm2) Note:1000μW-s/cm2=1mj/cm2(milli-joule/cm2) |

As a general guideline, the following are some typical UV transmission rates (UVT)

City water supplies | 850-980‰ |

De-ionized or Reverse Osmosis water | 950-980‰ |

Surface waters(lakes, rivers, etc) | 700-900‰ |

Ground water(wells) | 900-950‰ |

Other liquids | 10-990‰ |

Advantages

Effective: Virtually all microorganisms are susceptible to UV disinfection

Automatic: Continuous or intermittent disinfection without special attention

Fast: Water is ready for consumption as soon as it leaves the cell

Easy: Simple installation and maintenance. Minimum space requirements

Safe: No danger or way of overdosing, no addition of hazardous chemicals

Economical: Hundreds of gallons of water can be purified for a few cents per day

No Chemicals: No chlorine taste or corrosion problems

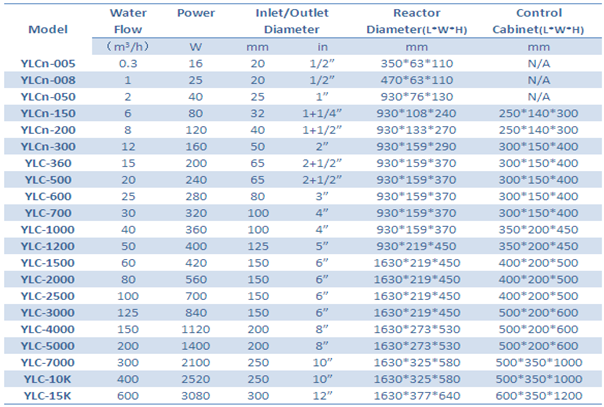

Technical Parameter

Could be customized

Application

Ultraviolet water purification systems are used in many applications that includes home/residential(both well water and municipal water supplies), commercial, and industrial. Here is a list of several applications where the power of UV water sterilizers are commonly used to treat and protect the water supply for contaminates such as bacteria and viruses. UV systems applications include private wells, campgrounds, hotels, bottlers, aquaculture, hospitals, food, cottages, restaurants, breweries, water systems, laboratories, marine, pharmaceutical, dairies and many other applications.

Small Flow Rate Water Disinfection Device 254nm UV light Sterilizer

1.What is the water flow of your water system?

2.What is your raw water to be disinfected?

3.Do you need the accessories like flow switch,UV intensity detector,timer,etc?

4.Do you also require other kinds of filters for prefiltration used in your water system?

China

China