Industrial Water Softening System Automatic Ion Exchange Cation Resin Water Softener

Ion exchange resin water softeners used in industrial boiler feeding water treatment use the Ion exchange technology to remove the hard elements(mainly the calcium and magnesium) in the water to achieve the softening treatment.It contains two resin jars in the time or flow regeneration type to make the system run 24 hours.

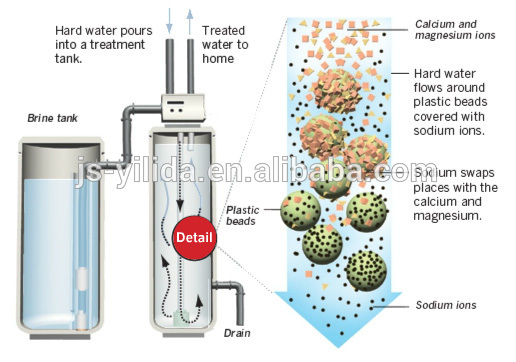

Working principle

When water contains a significant amount of calcium and magnesium, it is called hard water. Hard water is known to clog pipes and to complicate soap and detergent dissolving in water.

Water softening is a technique that serves the removal of the ions that cause the water to be hard, in most cases calcium and magnesium ions. Iron ions may also be removed during softening.The best way to soften water is to use a water softener unit and connect it directly to the water supply.

When hard water passes through the softening system's resin bed, it exchanges the hard ions in the water for soft ones, so only softened water passes through to your water system.

Once the resin bed fills up with hardness ions, it must be cleaned. Salt is typically used in the regeneration (cleaning) process and restores the resin to a “clean” state so the ion exchange process can begin again.

Regeneration Type

(1)Time type: it adopts microcomputer to control the time, when operation of the equipment reaches the pre-set time, it will automatically enter into the regeneration state, then the valve will run the other resin tank,the former resin tank won’t work until the other tank is regenerating,so the softener could achieve 24-hour-running.

(2)Flow type:it adopts control of turbine flow or electronic flow sensor, when the yield of softener reaches pre-set flow it will automatically enter the regeneration condition, the same as time type then the valve will run the other resin tank and the former resin tank won’t work until the other tank is in the regeneration state.

Technology index

Water pressure:0.18-0.6Mpa

Working temperature:1°c-55°c

Hardness of raw water: <8mmol/L

Operation method:manual/automatic

Hardness of effluent water: ≤0.03mmol/L

Water flow: 0.3-100 m3/hour

Control method: time or flow

Working electric: customized

Resin:001*7 strong acid cation exchange resin

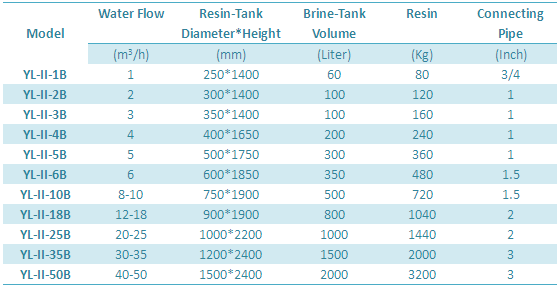

selection for water softener

Customization Available

Advantages

1,High degree of automation, stable conditions of supplying water, long service life

2, High efficiency, low energy-consumption, economic operating cost

3, Equipments structure is compact, occupy less foot-print

4, User-friendly, it’s simple and easy to installdebugoperate

Application

Mainly used in industry and civil water softening preparation, such as Boiler feed water make-up water, air conditioning system make up water, heat exchanger, power plant, chemical, textile, printing and dyeing, bio-pharmaceutical, Electronic system and water pretreatment.

Industrial Water Softening System Automatic Ion Exchange Cation Resin Water Softener

1.What is the water flow of your water system?

2.What kind control type for regeneration process you prefer,time type or flow type?

3.Do you have specific requirements for Ion exchange resin water softeners?

China

China