Industrial citric acid vibro sifter

♣ Brief Introduction of Industrial citric acid vibro sifter

The basic principle of Rotary vibrating screen for bentonite is the heavy hammer(unbalanced heavy hammer) installed in the electrical axis transform the motor’s rotary motion into horizontal, vertical, tilt motion( threeD movement) , then this movement passed to the screen surface. Adjust the upper and lower ends of heavy hammer’s phase angle, this can change the trajectories of materials on the screen surface. |

♣ Details of Industrial citric acid vibro sifter Sifter for grains' specifications are: 3-D Vibro screen is the most versatile equipment. It can separate powdered materials into different particles paragraph. It can also be used in solid-liquid separation of serous fluid. Classification: be divided into two kinds: carbon steel structure and stainless steel structure. two-layers type, three-layers type etc. There are many improvement type and additional devices of the screens. They can adapt to many product situations and requirements.

|

♣ Features of Rotary vibrating screen for silicon carbide

1, Function:Screening and filtering any powder or particle material 2, Diameter:400mm, 600mm, 800mm, 1000mm, 1200mm, 1500m, 2000mm 3, Movement Locus:Upwards, Left and Right Motion, Rotation Motion. 4, Sieve Layer: 1-5 Layers, the 1-3 layers is better. 5, Screen Size Range :10mm-500 mesh. 6, Driven Mode :Vibration Motor Driven. 7,Material:Carbon Steel, Material Contact Parts are Stainless Steel or full Stainless Steel. |

♣ Technical Parameters of Industrial citric acid vibro sifter

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

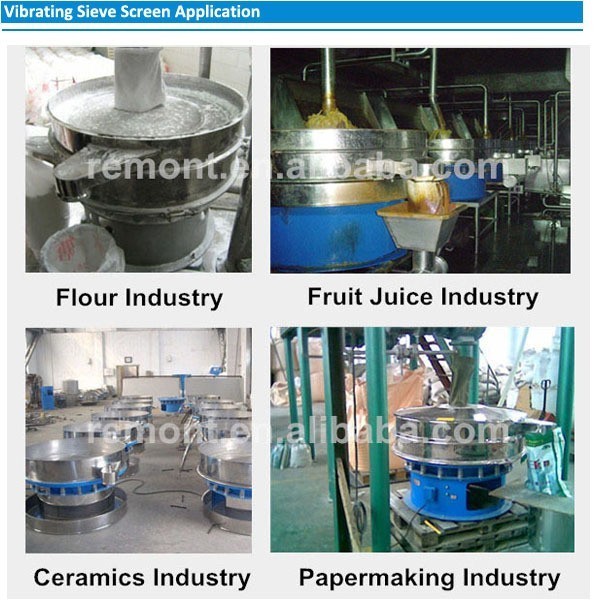

♣ Applications of Industrial citric acid vibro sifter Food industry: flour, milk powder, starch, fish meal, rice flour, quinoa, vitamin, spices, dextrin, drinks, juice, sugar, soy sauce, pineapple juice, yeast, the mother liquor etc

Chemical industry: Paint, tree cosmetics, PVC tree of cosmetics, citric acid, PE powder, washing powder, etc

Pharmaceutical industry: Pharmaceutical intermediates, medical auxiliary materials, this solution, west powder, and west solution, etc

Ceramic abrasive metallurgy industry: bentonite, attapulgite clay, aluminum silver pulp, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, spray soil grain, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

|

♣ Spare Parts of Industrial citric acid vibro sifter

|

|

|

♣ After-sales Service & Technical Supports of Industrial citric acid vibro sifter

1. Vibrating Separator installation,Debugging. Provide sand vibrating sieve machineinstallation files, technical data and related soft copies or videos etc 2. Vibrating Separator warranty The provider guarantee the carbon black vibration screen could meet production technical standard and performance requirements indicated in the contract. Warranty: 24 months for the machine after delivery,12 months for the motor after delivery. 3. Vibrating Separator technical support Our company will make occasional call to find problems and solve them in time. Provide technical support timely. 4. 24 hours website hot line service. For big Circular vibrating screen order,to dispatch technician is negotiable. Aftersales Guarantee.

|

♣ Packing & Shipping of Industrial citric acid vibro sifter

|

♣ Company Profile

Ø We are the leading manufacturer specialized in designing and manufacturing rotary vibrating screen in china with the experience of more than 20 years.

Ø Manufacturing according to the ISO9001:2008 quality control system guidelines.

Ø Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

Ø Workers are locals in china, low production cost.

|

♣ Notes:

Please provide us the following requirement, we will reply in time to meet your demands. (a)The name of material, granularity size, specific gravity, water content, viscosity, temperature. (b)Aim of using: get rid of impurity, filtration or grading. (c)Treatment volume: kg/h, L/h. (d)Sieve mesh (mesh or mm). (e)How long is the operation time every day? | ||||||||||

♣ Contact Us

|

China

China