Products Introduction Xinxiang Remont Machinery

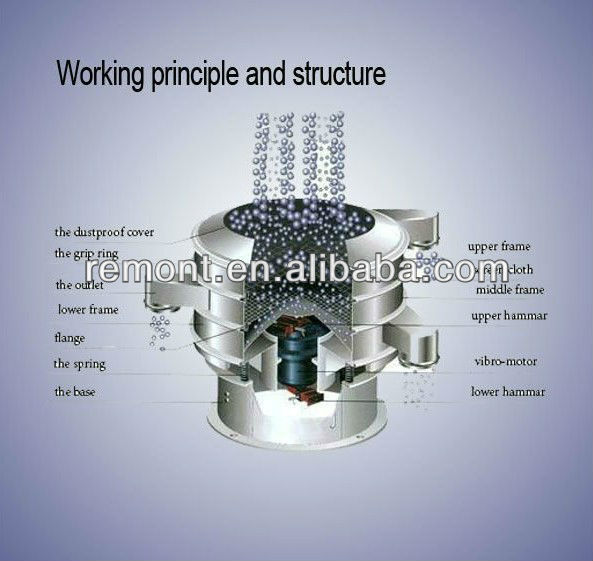

This series centrifugal vibration sieve is used for fine particle and powder material screening, with high screening capacity. It is widely used in the grain, liquid in the foodstuff,chemical pharmaceutical, grinding, ceramic and metals processing etc.

Products Application Xinxiang Remont Machinery

Ø Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

Ø Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

Ø Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

Ø Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

Ø Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

Ø Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc.

Technique Parametres Xinxiang Remont Machinery

| Model | Dimensions(mm) | Weight(kg) | Vaild diameter(mm) | Valid area(m²) | Inlet/outlet diameter(mm) | Power(KW) | Height of frame(mm) |

| M400 | 580*580*560 | 55 | 350 | 0.0962 | 150/110 | 0.25 | 90 |

| M600 | 800*800*750 | 98 | 550 | 0.2375 | 150/110 | 0.55 | 90 |

| M800 | 900*900*750 | 158 | 750 | 0.4416 | 200/140 | 0.75 | 120 |

| M1000 | 1160*1160*810 | 245 | 950 | 0.7085 | 250/150 | 1.47 | 120 |

| M1200 | 1360*1360*885 | 330 | 1150 | 1.0382 | 250/170 | 1.84 | 140 |

| M1500 | 1850*1850*990 | 478 | 1430 | 1.6052 | 280/180 | 2.20 | 170 |

| M1800 | 2200*2200*1050 | 690 | 1730 | 2.3494 | 350/220 | 3.70 | 170 |

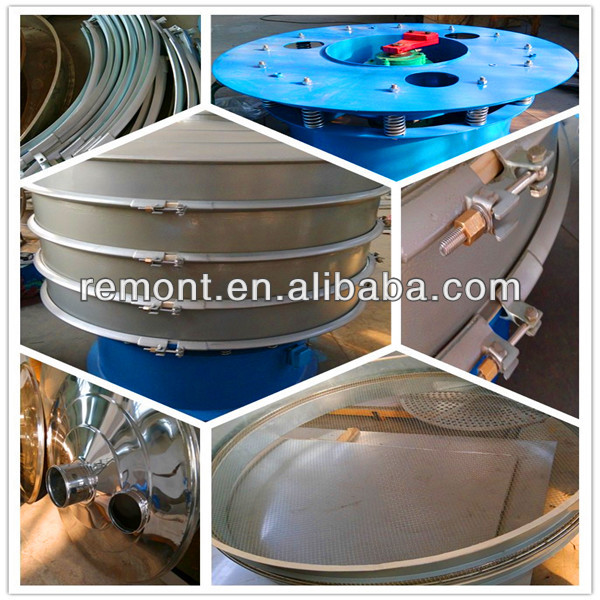

Production &Installation Xinxiang Remont Machinery

Company introduction Xinxiang Remont Machinery

Ø We are the leading manufacturer specialized in designing and manufacturing rotary vibrating screen in china with the experience of more than 20 years.

Ø Manufacturing according to the ISO9001:2008 quality control system guidelines.

Ø Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

Ø Workers are locals in china, low production cost.

After-sale service Xinxiang Remont Machinery

1. Vibrating Separator installation,Debugging.

Provide sand vibrating sieve machineinstallation files, technical data and related soft

copies or videos etc

2. Vibrating Separator warranty

The provider guarantee the carbon black vibration screen could meet production technical standard and performance requirements indicated in the contract.

Warranty: 24 months for the machine after delivery,12 months for the motor after delivery.

3. Vibrating Separator technical support

Our company will make occasional call to find problems and solve them in time.

Provide technical support timely.

4. 24 hours website hot line service.

For big Circular vibrating screen order,to dispatch technician is negotiable. Aftersales Guarantee

Note:

How could you choose suitable one? Please answer the following questions.

1. What’s the materials to process?

2. What’s the feature of the materials? Like density, moisture degree,input particle size and output particle size.

3. How many layers do you need ? And what’s the screen mesh about each layer?

4. What’s your capacity per hour?

5. What's material for the machine?Stainless steel or contact part stainless steel or carbon steel??

6. Other special requirement.

China

China