YBS tumbling sieve for EPS, citric acid, milk powder

WEILIANG tumbler screen machine are used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes. The WEILIANG YBS tumbler screen system features a range of customization options designed to meet extremely demanding requirements, as well as a broad variety of additional equipment options: Among these, the number of available screen cleaning systems is particularly worth mentioning, with balls, brushes, ultrasonic, and various combinations being of these options are available to prevent blinding and maintain efficient screening.

WEILIANG is the market leader manufacturer of tumbler screen in China, diameter from 1000mm to 2600mm, more than 1000 sets successful experiences now, adopt world class production equipment, just as TRUMFP laser, KUKA welding etc...

Technical parameters

Model | YBS1000 | YBS1200 | YBS1600 | YBS2000 | YBS2600 |

Diameter(mm) | 1000 | 1200 | 1600 | 2000 | 2600 |

Mesh area(sq.m) | 0.71 | 1.11 | 1.83 | 2.62 | 5.31 |

Mesh | 6mm - 0.028mm(500# mesh)/wire mesh, 7mm - 30mm/punching hole | ||||

Layer(s) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Power(kw) | 1.5 | 1.5 | 3.0 | 4.0 | 5.5 |

Mesh Cleaning | Bouncing ball, Ultrasonic system, Rolling brush |

Mesh cleaning: Silicone bouncing balls, Rolling brush and Ultrasonic system

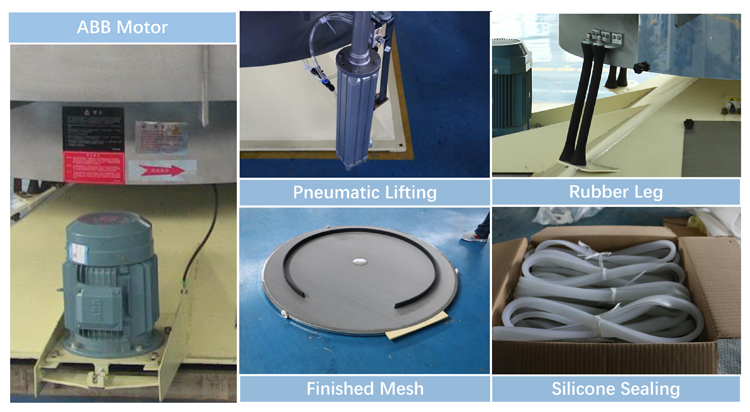

Special spares

Certificate

The company has passed the ISO9000:2008, CE, BV certifications

About Weiliang

Company Profile

Weiliang company was founded in 2006, 12 years production experiences of S49 vibrating screen, YBS tumbler screen, FYBS gyratory screener and WLQ airflow screen etc..., With world-class production equipment, and annual production capacity of more than 1000 sets screening machine, the goal in not only the domestic leader, but also to the world, and PK to world famous suppliers, to be the No 1 screening machine supplier in China.

Team

Our Team & Service

Basis service

1.Your sample material can be free analysis in our laboratory.

2.24 hours a week online & quick response within 12 hours.

3.Booking hotel and ticket for customers and Free transportation during visit our factory.

4. Production lead time and delivery time guaranteed.

Customized services

1.Professional R & D team to develop the new products as you requirements.

2.Help high-end customers to develop the local market

3.All packing and shipping can customized as per your requirements.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will be always available.

Customer Visit

Our customers came from different countries every year.

Our Package:

Standard package: plywood box

Use pallet for big machine into container directly

FAQ

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.

2.Guaranteed:

If products’ quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund. we use world-class production equipment for our screening machine.

3.How about price?

Yes, we are factory and be able to give you the best price with good quality, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

Contact us

Please show us the following questions, Then we can send you response quotation soon.

Your email address and telephone will not be shared or published!

The proper selection of the vibrating screen depends on the material, number of layers, every mesh size, capacity, material moisture, viscous and corrosive etc:

1. Screening material : _____

2. How many layer(s):_______

3. Every mesh size:______ mesh . ______ mesh. ...

4. Capacity: :________kg/ hour

5. Moisture, viscous, corrosive ________

6. Voltage:______V, Frequency:______HZ, 3 phase

7. Mild steel(Q235A), SS304, or SS316

Contact a WEILIANG professional- Gary now.

China

China