flour sifter machine for powder fiber dry herbs thyme

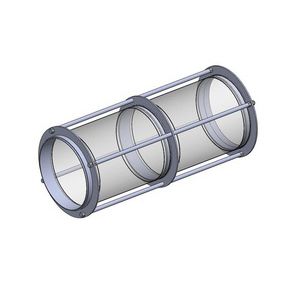

WORK PRINCIPLE:

The equipment screen mesh is a cylinder, material, after handling by screw feeder, mixing and atomization into a screen cage, so that the material also driven by centrifugal force and cyclone by rotating the blade, forcing material injection over the screen cage, fine material discharge from fine outlet, the coarse material which can not cross the screen cage, discharged from the coarse outlet.

CHARACTERISTIC:

- The whole machine is in a small size and little weight so that it is stable in operation, free of vibration and noise, and with its good sealing performance, it is free of dust and performs in a high efficiency.

- The shell of machine is in a new design that is easy to install and convenient to control.

- The machine can operate either in single unit or in multiple units ,and it is safe and reliable for long time operation.

- The screen-mesh can be cleaned automatically by cyclone.

- The machine has the function of re-crashing the agglomeration material.

- The new roller bearing units can prolong the using life.

- The machine can pair up with the pneumatic conveying systems, and directly crosses into the wind path to save the resources.

- New design: The gas protection system can transfer the purified air to the two ends of the device, which will reduce the temperature created in the operation of the device; it will form the air isolated layer to avoid the powder entering the bearing so as to increase the using life of the bearing effectively, reduce the maintenance frequency, and increase work efficiency.

- The machines can be specially designed to meet special requirements

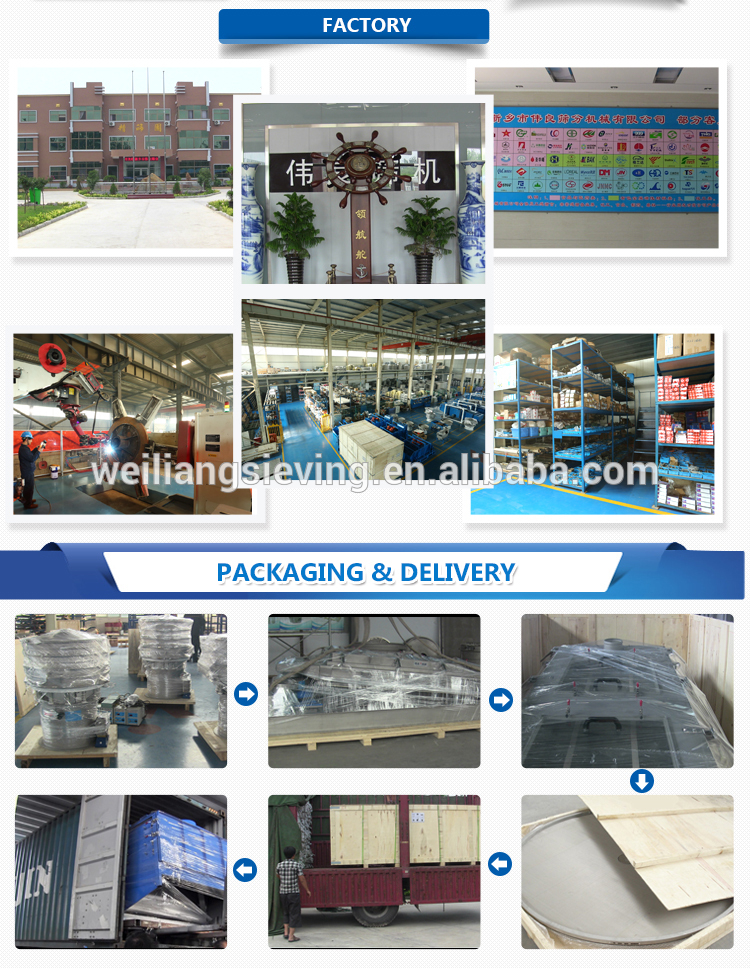

Xinxiang Weiliang Sieving Machinery Co., Ltd was founded in 2002, after 10 years efforts, and with the help of colleagues and customers, the company has developed quickly, step by step, has become the leading enterprise in fine screening field in China.

The company has domestic first-class production equipment, KUKA robot welding systems, 3000 tons hydraulic forming, famous laser bender machine, modern resin floor plant.

The company passed the ISO9001:2008, CE, BV certification.

Company built up a partnership with foreign well-know screening firms----- SWECO, ALLGAIER, RUSSELL.

The company’s main products--------

S49 rotary vibrating screen,

YBS tumbling (swinging) sieve,

FYBS square tumbling (swinging) sieve,

WLQ airflow sieve,

WWF white water filter

EPS dryer machine.

Contact Us

Please show us the following questions, Then we can send you response quotation soon.

Your email address and telephone will not be shared or published!

The proper selection of the vibrating screen depends on the material, number of layers, every mesh size, capacity, material moisture, viscous and corrosive etc:

1. Screening material : _____.

2. How many layer(s):_______.

3. Every mesh size:______ mesh . ______.

4. Capacity: :________kg/ hour

5. Moisture, viscous, corrosive ________.

6. Voltage:______V, Frequency:______HZ, 3 phase

7. Mild steel(Q235A), SS304, or SS316

Contact a WEILIANG professional- Leo now.

China

China