Horizontal Screw Discharge Continuous Decanter Centrifuge

Horizontal Screw Discharge Continuous Decanter Centrifuge introduction:

Decanter centrifuge uses the centrifugal sedimentation to separate the suspension, uses the spiral to unloading material.It is continuously charging, separating, discharging at full speed.It is used in the suspension(in 0.0005~2mm, concentration 2-40%) solid-and-liquid separation, size classification, liquid clarification .Especially ,it issuitable for the suspension separation that with difficult in filter cloth recycling, and the material with large concentration and big size range.

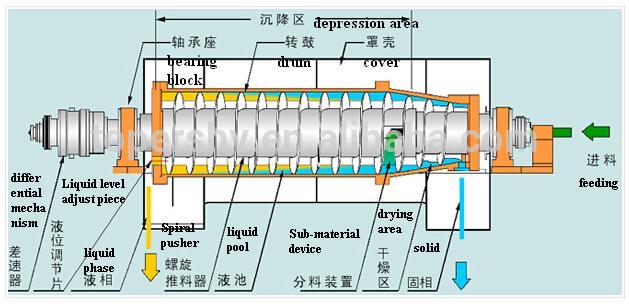

Working principle of cooking oil decanter centrifuge

There is spiral which is the feeding spiral which is has the same axis with the drum.The spiral and the drum rotate in different speed but in the same direction.The rotate difference is caused by the differential.The suspension enters the spiral through the feeding pump in the centre, when it starts to speed up the material goes into the drum.Under the effect of the centrifuge force, the relatively heavy solidoid sediments into slag blanket on the surface of the drum wall, then the spiral push the slag blanket to the drum cone section for further dehydration, latter it will be discharged from the small section slag hole.While the relatively light liquicdoid forms the inner liquid cycle, and it will be discharged from the large end overflow gate.

Main technical parameters of cooking oil decanter centrifuge

Models | Basket Dia(mm) | Length-Diameter Ratio | Rotation rate of basket(r/min) | Relative Centrifugal force | Power of motor(Kw) | Weight(kg) | Overall Dimensions(l*w*h)(mm) |

LW220*660 | 220 | 3 | 4800 | 2840 | 7.5-11 | 900 | 1650*1150*700 |

LW220*880 | 220 | 4 | 4300 | 2280 | 7.5-11 | 1000 | 1850*1200*750 |

LW300*1140 | 300 | 3.8 | 3750 | 2370 | 11-15 | 1500 | 2100*1300*650 |

LW355*1160 | 355 | 3.3 | 4000 | 3100 | 22 | 2020 | 3067*920*1060 |

LW355*1460 | 355 | 4.1 | 4000 | 3100 | 22 | 2200 | 3365*920*1060 |

LW400*1200 | 400 | 3 | 3500 | 2750 | 18.5-22 | 2500 | 2400*1650*900 |

LW420*1680 | 420 | 4 | 3600 | 3000 | 22 | 2430 | 3320*1000*1060 |

LW450*1350 | 450 | 3 | 3500 | 3080 | 30 | 2230 | 3750*1090*1250 |

LW450*1800 | 450 | 4 | 3500 | 3080 | 30-37 | 3500 | 4200*1090*1250 |

LW530*1800 | 530 | 3.4 | 3200 | 3040 | 45-55 | 3920 | 4565*1230*1350 |

LW530*2120 | 530 | 4 | 3200 | 3040 | 45-55 | 4200 | 4885*1230*1350 |

Main usage of the of cooking oil decanter centrifuge

1 the separation of industrial and domestic sewage dewatering

2 starch washing, grading dehydration

3. Soybean, wheat protein dehydration

4 fish meal, fish dehydration

5. Distillers dehydration

6 Juice Purification and dehydration of pulp fiber

7 Separation and purification of animal and vegetable oils

8 Separation and purification of coal tar

9. Kaolin, graphite classification and dewatering

10. fuel, paint grade and dehydration

11. ore grade pulp and dehydrated

12. Coconut milk, Avocado, coconut oil purification and separation

For sludge dewatering of cooking oil decanter centrifuge

We provide you reliable and fast package and variety kinds of transportation way to insure you get the goods in time and safely.

Since 2006,Our equipment has been exported to many countries all over the world such as India, Pakistan, Sri Lanka, Bangladesh, Indonesia, Philippines, Malaysia, Vietnam, Singapore, Turkey, Israel, Burma, Jordan, Yemen, Iran, Iraq, Afghanistan, Syria, Kuwait, Kazakhstan, Qatar, Korea, Azerbaijan, The UAE, Bhutan, Thailand, Lebanon, Bahrain, Egypt, Libya, Ethiopia, Kenya, Somalia, Tanzania, Liberia, Ivory Coast, Ghana, Nigeria, Cameroon, Chad, Guinea, Zambia, Zimbabwe, Malawi, Congo, Gabon, Angola, Mozambique, Botswana, Namibia, South Africa, Argentina, Bahamas, Bolivia, Brazil, Canada, Columbia, Chile, Cuba, Venezuela, Ecuador, Guatemala, Guyana, Honduras, Haiti, Mexico, Peru, Uruguay, Paraguay, Surinam, Australia, Russia etc.

Our manufacturing base of filter equipment mainly produce full automatic or semi-automatic membrane filter press, recessed filter press, belt filter press, centrifuge, etc. All these products are widely used in mining, metallurgy, petroleum, chemical, medicine, textile, printing and dyeing, paper making, food, alcohol, inorganic salt, coal washing, and waste water processing industry.

Our products has passed ISO9001 International Quality Management System Certification and is exported to America, Canada, Chile, Bolivia, Indonesia, Malaysia, Israel, Iran, Egypt, Turkey, Romania, Sweden, Finland, etc. about more than 50 countries and area. We have won good reputation depends on our best qualified products and after-sales service. Warmly welcome new and old friends all over the world to come our company for good cooperation with each other!

FILTER PRESS SERIES:

Filter presses can be divided into plate and frame type and are used for solidliquid separation of various suspending liquid in intermittent pressure filtration. Filter plates are pressed by pressing devices and suspending liquid is pumped into the filter chamber. Solid particles and separated through filter cloth. The products are simple in structure but good in separating effects, convenient in use, and widely applicable to mining, metallurgy, petroleum, chemical, medicine, textile, printing and dyeing, paper making, foodstuff, alcohol, inorganic salt, coal washing, dyestuff and sewage treatment industries.

All of Toper's products:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compress filter press

4. Mechanical compress filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Round plate filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY rotary drum thickning/dehydrating belt filter press

14. Triple-belt thickning and dehydrating filter press

15. SS type three-foot upper discharge centrifuge

16. SD type three-foot and filter bag hoist discharge centrifuge

17. PD type filter bag hoist discharge centrifuge

18. Centrifuge of up discharge, three foot, clean series SSB, SB

19. SX type manual top discharge centrifuge

20. PS type manual top discharge centrifuge

21. SGZ type automatic scraper bottom discharge centrifuge

22. PGZ type scarper bottom discharge centrifuge

23. LW series decanter centrifuge

24. Tubular centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomite filter

28. Filter late

29. Filter cloth

30. Vacuum disc filter

China

China