Nickel Sulfate Vibrating Fluid Bed Dryer

1. Nickel Sulfate:

Nickel sulfate, usually refers to the inorganic compound with the formula NiSO4(H2O)6. This highly soluble blue-coloured salt is a common source of the Ni2+ ion for electroplating.

The salt is usually obtained as a by-product of copper refining. It is also produced by dissolution of nickel metal or nickel oxides in sulfuric acid.

In the electroplating industry, it is used as the main raw material for electroplating nickel and chemical nickel. Printing and dyeing industry, used as a reducing dye mordant, and for the production of phthalocyanine blue complexing agent. The pharmaceutical industry, for the preparation of vitamin C oxidation step of the catalyst.

2. Take a proposal of NiSO4 ZLG-7.5× 0.9 fluid bed dryer as an example:

1.0 Drying equipment main performance parameters:

1.1 Equipment Name: vibrating fluidized bed dryer

1.2 Equipment Model: ZLG-7.5 × 0.9, bed area: 6.75 square meters

1.3 Dry section: 6.5 meters, dry area: 5.85 square meters

1.4 cooling section 1 meter, cooling area: 0.9 square meters

1.5 Drying air temperature: ~ 120 ℃

1.6 Heating method: saturated steam gauge pressure 0.4Mpa, steam consumption: 480Kg / h

1.7 product collection methods: host out of cloth + bag dust

1.8 installed power: 33.4Kw, real consumption of about 70%, that is, 25Kw / h

3. Features:

1. With high strength corrosion resistance

The bed material is made of stainless steel and the inner wall is coated with FRP

Made of carbon steel under the bed made of FRP, external insulation made of carbon steel coated with anti-rust paint

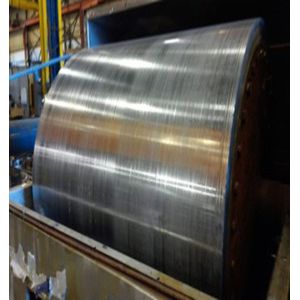

2. The porforated plate structure

We called it reverse peak shape hole perforation plate, please see the example photos.

3. Tail pipe and ductwork system is made of FRP.

4. A brief presentation of our company:

Overseas Installation:

Technical solutions meeting with our customers:

Overseas Installation:

If you need further information, please contact us freely, we will do our best to cooperate with you.

China

China