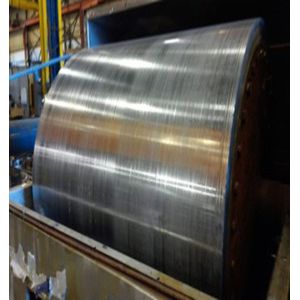

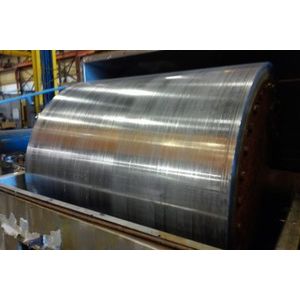

industrial food double drum dryer roller rotary drum dryer

Description

HG Drum Pharmaceutical Conductive style drying machine (Drum dryer) (drum drying Equipment) is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum. Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film, to evaporate the moisture in materials film so as to dry materials. Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the blade, and are conveyed, collected and packed.

Features

1.High heat efficiency: The heat transfer of the cylinder dryer is heat conduction and the conducting direction keeps identical with operation circle. Most of the heats can be used for evaporation of wet materials on the wall the cylinder. The efficiency can reach 70-80%.

2.Flexible operation elasticity and wide application: Various drying factors of the dryer can be adjusted, such as concentration of the liquid, thickness of material film, temperature of heating medium, rotating speed of the drum, and etc. These factors can change drying efficiency of the cylinder dryer. As these factors have no interrelations each other, it brings great convenience to dry operation and makes it applicable to dry different materials and meet different production requirements.

3.Short drying period: The drying period of materials is normally 10 to 300 seconds, so it is suitable for heat-sensitive materials. It also can be pressure reducing operated if it is put in vacuum vessel.

4.Fast drying rate: The thickness of the material film on the wall of the cylinder is very thin. Normal, thickness is 0.3 to 1.5mm. The directions of heat and mass transmittal are identical so the evaporation strength on the surface of material film can be 20-70 kg.H2O/m2.h.

Working Principle

HG Series Cylinder Scratch Board Dryer is a kind of rotating continuous drying equipment with internal heating conducting function. The material film will stick to the bottom of the rotating cylinder. The heat is transferred to the internal wall of the cylinder through piping system and it will be conducted to the external wall and material film. The moisture of the wet material film will be easily evaporated and the dried material will be scraped from the cylinder surface and transfer to the packing area by the screw conveyor.

China

China