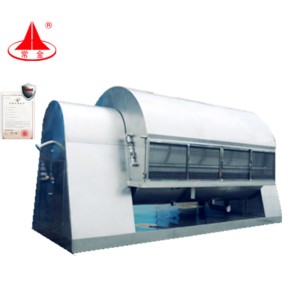

GT Rotay Drum Dryer For Drying Starch

Application:

It is suitable for drying liquid raw material or sticky material in chemical industry, dyestuff industry, pharmaceutical industry, foodstuff industry, and metallurgy industry and so on.

Principle :

In these the food is spread over the surface of a heated drum. The drum rotates, with the food being applied to the drum at one part of the cycle. The food remains on the drum surface for the greater part of the rotation, during which time the drying takes place, and is then scraped off. Drum drying may be regarded as conduction drying.

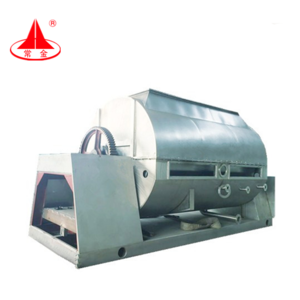

1. High thermal efficiency. The principle of heat transfer of rotary drier is heat conduction which heat conducting direction keeps identical with operation cycle. Except cap heat dissipation and radiation loss, all heat energy can be used for evaporating wet materials on the wall of roller. Thermal efficiency could reach 80%-90%.

2. Large operation elasticity and wide application. Various drying factors of the rotary drier can be adjusted, such as density of feeding materials, thickness of materials film, temperature of heating medium, rotating speed of roller etc, which can change drying speed. As these factors have no interrelations with each other, it brings great convenient to dry operation, and makes it applicable to suit various materials and to meet different requirement of production.

3. Short drying period. The drying period of material is normally 10 to 15 seconds, so it is suitable for heat-sensitive material. It can be also working under less pressure condition if it is put in vacuum device.

4. Drying rate is quick. As material film coated on the wall of roller is very thin. Normally thickness is 0.3-1.5 mm, plus heat and mass transfer direction are identical, the evaporation capacity on the surface of film can keep at 15-70kg.H2O/m2.h.

For more: https://jinlingdrying.en.alibaba.com

China

China