Silica Sand Rotary Drum Dryer Brief Introduction

The new type rotary dryer machine are used for drying the high moisture material to a suitable moisture, so that the material can be reached a high efficient use value.

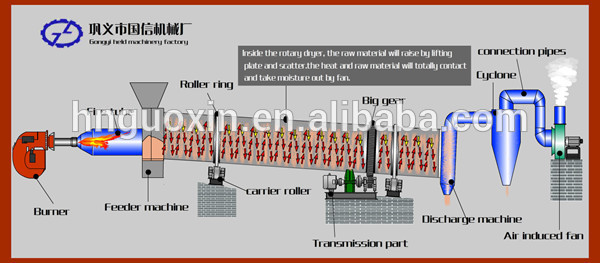

What the consist of silica sand rotary drum dryer:

Feeder machine

Discharge machine

Temperature detector

Roller ring

Big gear

Transmission parts

Carrier roller

Cyclone which is collect the dust from lignite drying machine.

Fan

Connection pipes

Furnace Lifting plate

Application of silica sand rotary drum dryer:

It is widely used in the field of building materials, metallurgies, chemical industry, cement and so on.

It can dry slag, coal powder, mining powder, clay, sand, limestone,solid dryer, palm fiber, manure, slurry, manganese ore and so on. It is made into rotary body, lifting blade, driving device, supporting device etc.

We supply the following dryer: wet material rotary dryer, sand dryer, sawdust dryer, coal dryer, coal slime dryer, bentonite dryer, ore concentrate dryer, wood chip dryer, cassava dryer, gypsum dryer, cow dung dryer.palm fiber dryer,compound fertilizer dryer, aminal forage dryer

The heating source of silica sand rotary drum dryer:

You can use coal, natural gas, electricity, oil,biomasss,LPG and wind power to heat the dryer machine.

Generally Speaking, the choice of fuel is based on the local suitable heating source,so as to achieve the heating source comprehensive utilization.Also,the cost of the dryer can be reduced with local highly cost effective heating source.

Working Principle of silica sand rotary drum dryer:

¤The material enter into the drying machinery by conveyor,at the start of the dryer have furnace,it will provide the heat for the dryer and the end of the dryer have fan,the fan absorb the heat enter into the dryer,inside the dryer have negtive pressure,so the heat must enter into the bentonite drying machinery.

There have lifting plate,it will raise up the raw material,so that the heat and raw material will be totally contact inside the bentonite drying machine.

¤ The dried material will come out from the discharge machine.

¤ The cyclone is collect the dust from the drying machinery.

Advantages Of silica sand rotary drum dryer:

1.The drum dryer have resonable structure, dry the material quickly.

2.Simple design, self-insulation, improve the heat efficiency to exceed 80%.

3.Structure delicate, stable operation.

4.gooddryingperformance, coal consumption <8kg when drying 1 ton material.

5.The fuel can be coal, oil, natural gas etc, dry mass, granule and powder material.

6.Reduce land area for 50% compared to single drum rotary dryer, so construction investment is saved 50%,power consumption saved 60%.

7.Finished product moisture can be adjusted depends on requirement of client.

8.Lower outlet tempreture, loonger dust removal using life.

9.Drive by tug not gear.

10.Finished product tempreture lower than 60°C, packing can be done continuously.

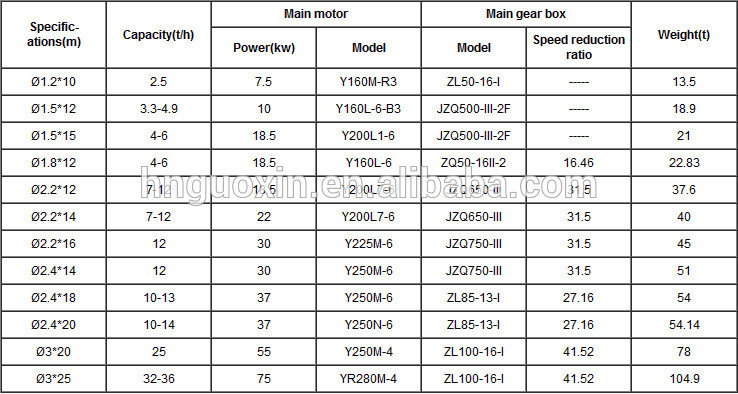

Main technical parameter of silica sand rotary drum dryer:

Installation of silica sand rotary drum dryer:

1. The device should be installed on a level concrete foundation with anchor bolts.

2. When installing, you should pay attention to the main body vertical and horizontal.

3. After installation check all bolts and host doors, if loose, please fasten them.

4. Configure the power lines and control switch according to the device's power

5. After checking, empty load test, if the test normal, it can be used to produce.

Training & Guarantee

Training is FREE to every customer. Whenever you need us, for installation, maintenance, or proper use of our company machines, we will be right there for you. In addition, we provide 2-years warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

FAQ

1) How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.

2) What guarantee do you provide?

If the quality is not consistent with the description as we said or promised before you place order, we promise you 100% refund.

3) How about price?

We have our own factory and can give you the lowest price, besides, we have a policy that " for saving time and absolutely honest business attitude, we quote as low as possible, discount can be given according to quantity"

Our Services:

Pre-sale services:

Act as a good advisor and assistant of clients; enable them to get rich and competitive

from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clients’ special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer

Services during the sale:

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

1) Pre-check and accept products ahead of delivery.

2) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

Provide considerate services to minimize clients’ worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

8) Provide maintenance for big items.

9) The most preferential prices to provide customers the quick-wear parts.

Delivery At Our Factory

Cooperation Customer:

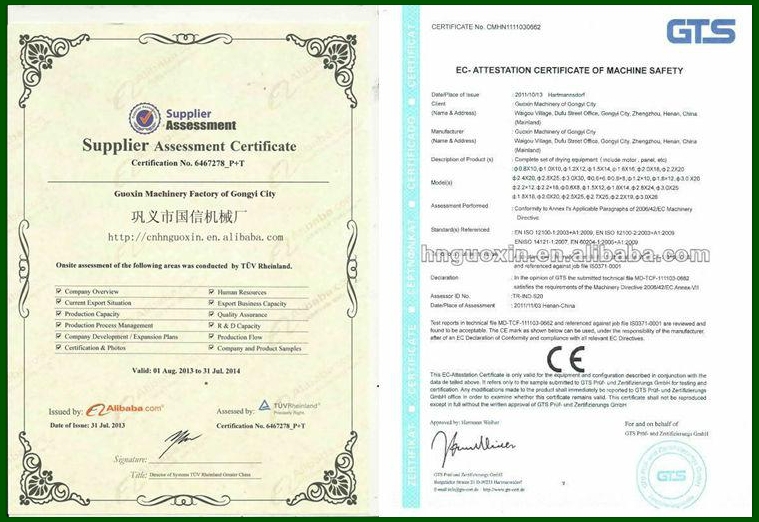

Qualified Certificates

Factory and Workshop

If any question,pls contact Cathy Wang freely.

China

China