Working principle

The cylinder screen-mesh of this device is placed the base machine. The materials mixed with airflow and atomization pass the screw conveyor device, enter the net tube. The undersize materials are sprayed through the screen cloth and diacharged from the fine stuff outlet under the action of centrifugal force and cyclone propelling power, which caused by the rotor vane inside the net tube. The oversize material, which can not cross the net, is discharged from the rough material outlet along inside surface of the tube.

Main Features

1.The whole machine is small in size and light weight so that it is stable in operation, free of vibration and little noise. With its excellent sealing performance, it is no dust pollution and can gain a high screening efficiency.

2.The updated apperance design of this machine makes it easy to install and convenient to operate.3.The machine can operate either in single unit or in multiple units, With its reliable quality and safe operation, this machine can gain a long service life.

4.The screen-cloth can be cleaned automatically by cyclone,

Technical Parameter

| Model | Screen cage size mm(diameter*length) | Screen material | Application |

| BL 18-65 | 180*650 | SUS304 or Q235 | 325 mesh below |

| BL 30-100 | 300*1000 | 325 mesh below | |

| BL 50-130 | 500*1300 | 325 mesh below | |

| BL 65-180 | 650*1800 | 325 mesh below |

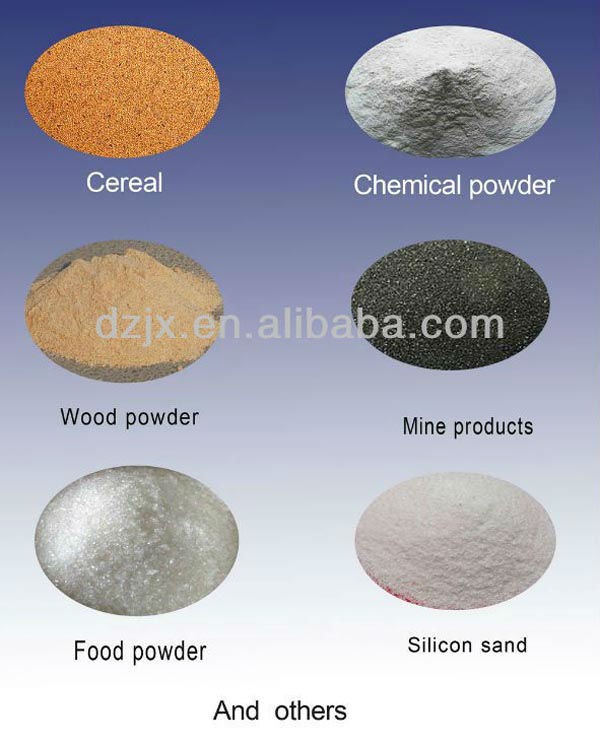

Application

Food Industries: starch, spices, seasonings, milk powder,egg powder, rice flour, wheat flour, beans powder, food additives etc.

Chemical Industries: fertilizer, detergent powder, talcum powder, dyestuff, rubber, resin, pigment, cosmetic, coatings, PVC powder, CPE powder etc.Particularly suitable for light weight materials

Machine picture

Production process

About us:

We are direct factory of Vibrating Screen, Conveyor equipment and Mixer for 30 years, we are glad to build longlasting business relationship with you.

We have the enterprising and energetic team of excellence who are dedicated to their career. More than 200 staff work for us, including 65 technicians and engineers with senior title . In 2000, we established CAD workstation earlier than others in China.

Pre-Sales Service

* Inquiry and consulting support.

* Free solutions

* View our Factory.

*Make plans for choice according to the needs and special requirements of users in different sectors

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

*Establish long-term and friendly relationship

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size(length & angle for conveying series) & ideal capacity for proper type, granularity distribution is recommended. product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry. With our experienced quality control team, we are trying to offer most of our customers the product with bset quality. However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China, China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

China

China