vibrating sifter

Brief description:

Dongzhen Made screening machinery is a universal device designed with full demonstrability and utmost optimization and have the tend to be standardized. It is very suitable to separate small particle, minuteness powder and the separation of solid and liquid.

Scope of application:

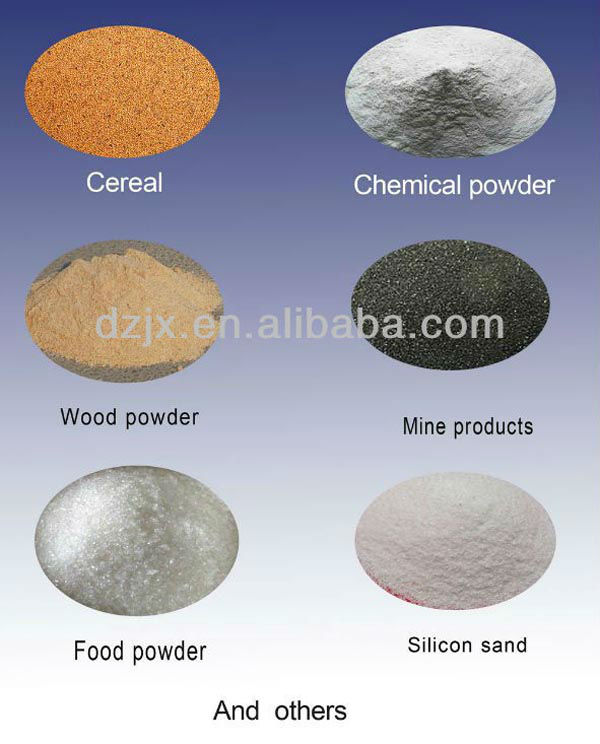

Dongzhen Made screening machinery is widely used in many industries, such as mining, building materials, metallurgy, casting, abrasive material, chemical, light industry, medicine and food industries.

Features:

1. Dongzhen Made screening machinery is one of precised powder sieve, it is of high efficiency, screening efficiency exceeds 90%.

2. It adopts whole sealing structure design to guarantee no dust pollution, no leaking liquid, no material left in machine, and no dead angle in the net frame.

3. Small noise and light weight, easy to be installed and maintained.

4. The outlet can be adjusted at any angle, and it is easy to replace the screen.

5. The rubber ball device can reduce the material jam on the screen.

6. By adding ultrasonic device, superfine materials up to 600 mesh can be sieved.

Principle of the structure:

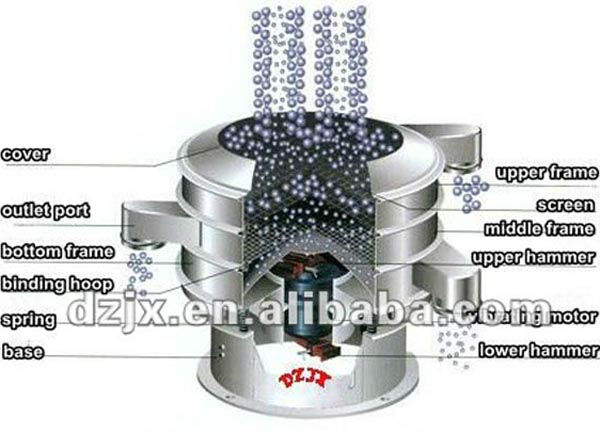

It uses vertical vibrating motor as the source of vibration, with eccentric hammer on both sides of motor, making material do level, upright and incline movement, then the material passes these through surface of the screen after overall screening. Adjusting the phasic angle on both sides of the motor can change the movement track of the surface screen, which helps screen different materiel in different situation successfully.

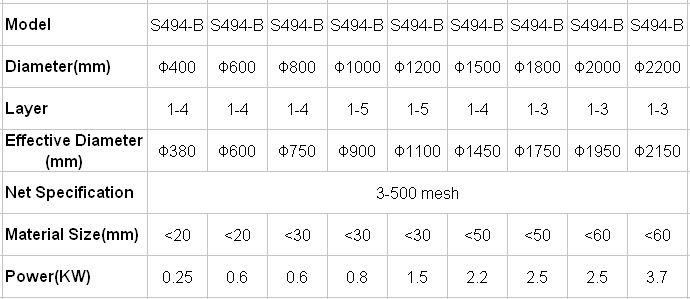

Technical parameter:

Machine structure:

Machine picture:

Different layers and materials:

Top quality motors:

Applicable materials:

Packing and shipment:

About us

China

China