SXG series high speed rotary catalyst flash dryer

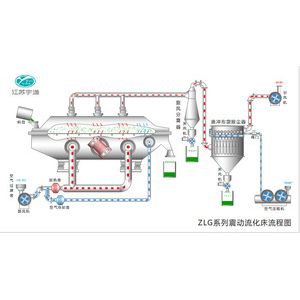

Working Principle of SXG Rotating Flash Drying Machine

Hot air in tangential direction enters into the bottom of the rotary flash dryer, and forms strong rotational wind field under the action of stirrer. The materials get into the drying equipment from screw feeder, under the strong effect of the high-speed rotating impeller, the materials are dispersed after being rubbed and sheared. Bulk materials are quickly crushed and fully contacted with the hot air in order to complete drying. Dehydrated dry materials rise with the hot air, the grading ring will retain the large particles and the small ones will be excluded from the rotating flash drying machine through the ring center. The cyclone separator and dust remover will recover these materials. The wet or bulk materials will be threw to the container wall by centrifugal force, and fall into the bottom of the flash dryer to be crushed and dried again.

Application

1.Inorganic materials: boric acid, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, metal hydroxide, heavy metallic salt and compound cryolite.

2.Organic materials: atrazine, lauric acid, benzoic acid, sodium oxalate, cellulose acetate

3.Ceramics: kaolin, silica and calay

4.Dyes: anthraquinone, black iron oxide, butyrate, titanium hydroxide, zinc sulfide, azo dyes

5.Food: soy protein, gelatinized starch, vinasse, triticin, wheat starch

6. Pharmaceuticals: analgin (The first domestic application of flash dryer)

Technical Parameters of Rotating Flash Drying Machine

Model | Diameter (mm) | Dimension (mm) | Power (kw) | Air Volume (m3/h) | Water Evaporation (kg/h) | Floor Space (m2) |

SXG-2 | 200 | 300 × 2800 | 0.75 to 2.2 | 300 to 800 | 10 to 20 | 3.5 × 2.5 |

SXG-3 | 300 | 400 × 3300 | 3 to 4 | 600 to 1500 | 20 to 50 | 3.8 × 2.7 |

SXG-4 | 400 | 500 × 3500 | 4 to 7.5 | 1250 to 2500 | 25 to 70 | 4 × 3 |

SXG-5 | 500 | 600 × 4000 | 5.5 to 11 | 1500 to 4000 | 30 to 100 | 4.2 × 3.2 |

SXG-6 | 600 | 700 × 4200 | 7.5 to 18.5 | 2500 to 5000 | 40 to 200 | 4.25 × 3.25 |

SXG-8 | 800 | 900 × 4600 | 11 to 18.5 | 3000 to 8000 | 60 to 600 | 4.5 × 3.5 |

SXG-10 | 1000 | 1100 × 5000 | 15 to 30 | 5000 to 12500 | 100 to 1000 | 4.75 × 3.75 |

company introduction

Jiangsu Yutong drying engineering Co.,ltd was established in 2000,its located in a famous town called “Jiaoxi” town occupying over 50 Chinese arces field with 16000 square meter building area , among 150 staff,

Yutong company is professional manufacturer of drying machines the granulator mixing machine grinder machine. Concentrating, nitrogen closed circulating and so on in chemical industry pharmaceutical industry foodstuff industry agrochemical industry, environment project. New material and new energy petrochemical, medicine, electricity, mine industry etc.

We have the implemented a strict and complete quality control system, when we finish each equipment we will have testing in factory in order to ensue each equipment fit the customer quality requirement. Our products conform to international standard such as GMP, SGS.

We have R&D team each year we develop 1-2 new product. Also we have professional after sale team they will help u installation debugging production on time.

Our company adheres to “science and technical is first productivity, innovation promotes development” ”fair competition, honesty, quality and innovation to win” for the purpose, and strive to achieve “I have when others lack, I am excellent when others have, I innovate when others excellent”, with scientific and rigorous attitude, the concept of excellent, we will do our best for each machine to strive to achieve realistic innovation, cooperation and win-win.

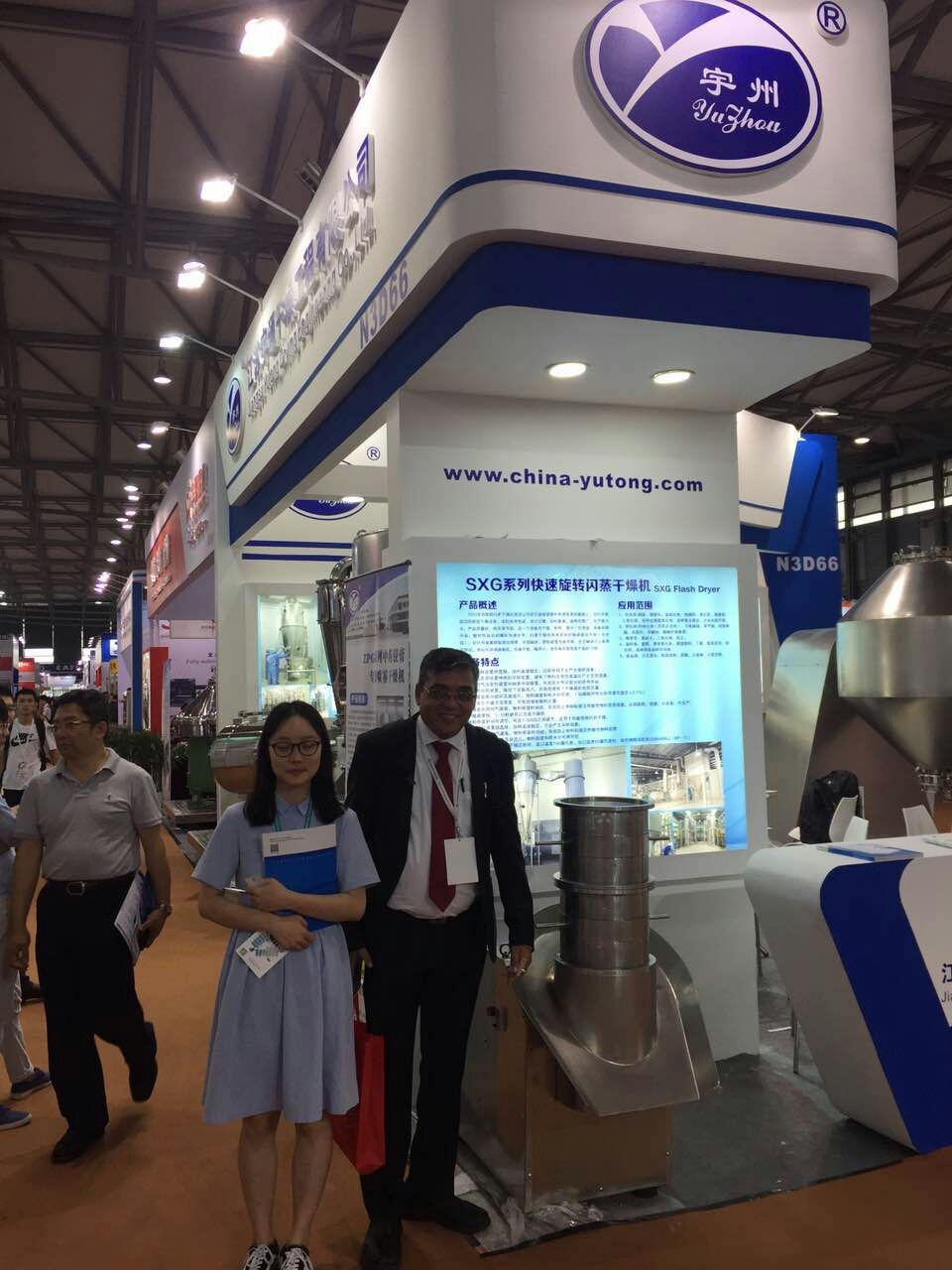

Exhibition

so on...

so on...why choose us

1.Jiangsu yutong drying engineering was established in 2000 with more than 17 year experience 150workers 16000square meter and recently we will expasion factory areaaf

2.We have a professional technical team we can make scheme as u requirement

3.We have after service team they will help u installation debugging and production on time

4.Before the machines leave our factory we will have the testing to make sure the machines fit u requirement then arrange shipping

5.Delivery time short, good quality competitive price

6.Each year develop the new products

7.Customer can com to jiangsu yutong drying engineering co.,ltd for testing

8.ISO SGS certificate machine fit GMP requirement CIQ certificate

FAQ:

Q1. What are your terms of packing?

A: Generally, plywood case suitable for shipping container.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What are your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 60 to 90days after pre-paid need according to the actual sitation

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q6: How do you make our business long-term and good relationship?

A1:We keep excellent quality, thoughtful after-sales service and competitive price to ensure our customers’ benefit; A2:We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

China

China