Product Introduction

Based on our rich enginnering experience and the traditional technology,we improved the transimmision system and the material breaking device and finally improved the drying efficiency and overall performance of the spin flash dryer.

The spin flash dryer system is mainly composed by heating system,feeding system,spin flash dryer,bag dust collector and drought fan.

The new drying system only uses bag dust collector to separate product,which reduced the system resistance as well as power and energy consumptioin of fans.Working life of filter bags get extended by 30%-60% due to the low system resistance.

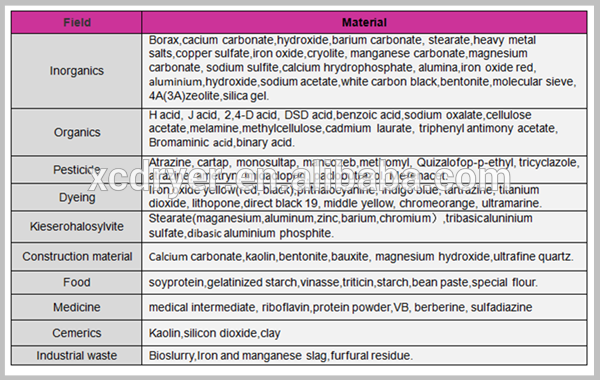

Applicable materials

Main Features

1) Feed is dried into powder for once,no need regrinding;

suits to filter cake and paste material.

2) Double air duct, tangential air, uniform radical velocity.

3) Continuous operation,stable running,can be PLC automatic control.

4) Final moisture content and fineness can be effectively controlled by coordination of swirl blades and inlet air speed.

5) Special rotary blades distributed structure;

Less abrasion, large interface, stronger cutting force.

6) Suits perfectly to thermal-sensitive material.

7) Short resistance, high thermal efficiency, friendly operating environment.

8) New sealing structure of the drying tower, long bearing life, bearing block with water

circulating jacket cooler.

9) Easy maintenance,long working life.

Technical advantages:

1) Special designed stucture: the leaned blades are special designed,and distance of the flat blades is larger than

common flash dryer. Singles blade can be taken down from the breaking device.Wet raw material can be broken more efficiently by the special rotating blades.

2) Special structure of the classification ring,which garantees the high quality of the product.

3) Special super low pressrue ash-cleaning system,high quality filter bag,large filter area.

4) Dryer thickness: 5-7mm thick plates.

5) Large size volute

6) Big annular space:the annular space is between the air chamber and the drying chamber,big annular space can keep the air in a optimum speed.

Working Principle:

Hot air enters into the spin flash dryer tower tangentially from the drying tower bottom, and then forms high-speed spinning air flow in the drying tower. The annulus is adjusted to give an appropriate air speed according to material properties.

Material which is to be dried is fed into the drying tower directly via a screw feeder, then dispersing and spinning in a high speed together with the air flow.

Large-size and wet particles fall down by gravity, and being crashed into tiny particles after falling onto the tower bottom, then rising up rotationally with the high-speed airflow.

Multi-layer swirl blades are installed inside the drying tower to form a stable fluidized bed which guarantees the very low final moisture and avoids the products from being affected by the fluctuation of the initial moisture. Aside from this, the blades can also classify the particles and ensure the required residence time.

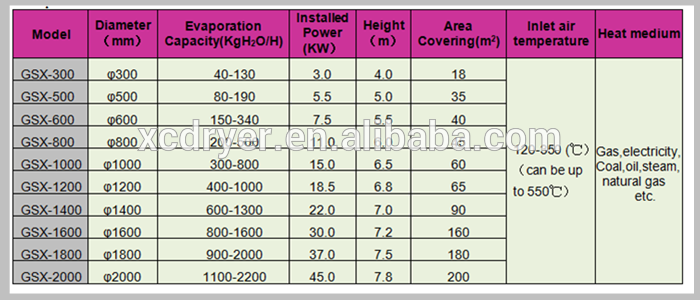

Specifications

Machine Parts

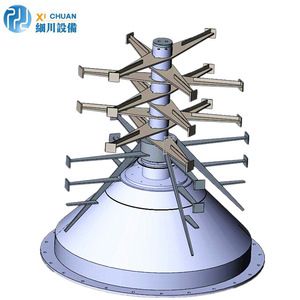

Name: Rotating blades

Brand: Xichuan

Original: China

Special designed rotating blades;

Larger distance of the flat blades is larger than common flash dryer.

Singles blade can be taken down from the breaking device.

Wet raw material can be broken more efficiently by the special rotating blades.

Main Features

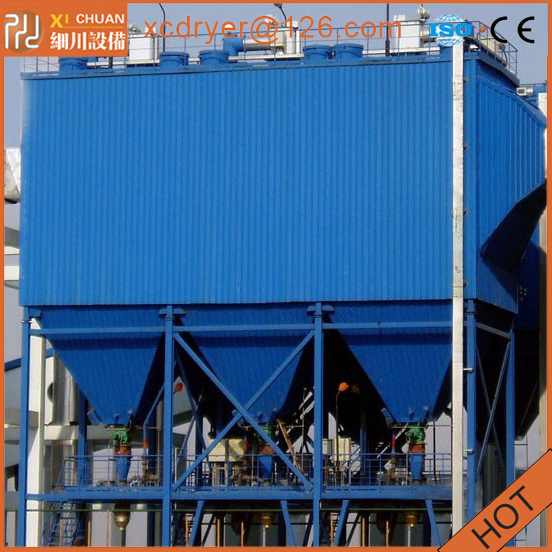

Name: bag dust collector

Brand: Xichuan

Original: China

filter bags:high performance filmed needle felt;

Using bag dust collector instead of the combination of cyclone and bag dust collector reduced the system resistance as well as the power and energy consumptioin of fans.

Machine Parts

Name: feeding system with agitating silo

Brand: Xichuan

Original: China

Special designed screw feeder with agitating silo for sticky filter cake and pasty material.

Conveying speed can be adjusted by the frequency convertor.

Main Features

Name: rotary discharge valve

Brand:Xichuan

Original: China

hihg performance rotary discharge valve is used for product discharging from the bag dust collector.

After-sale service

Engineers availabe to guide the installation and debugging.

| Packaging | |

| Size | according to actual equipment size |

| Weight | 1-20t |

| Packaging Details | Loose package for large size machine that exceeds the standard size of container. Container for small parts. |

paddle dryer

91.8% Response Rate

fluid bed dryer

91.8% Response Rate

bag dust collector

91.8% Response Rate

China

China