Centrifugal Separator for fine powder

BL series automatic separator machine 's principle is feed the materials into a screw conveyor and a rotor rotating at high speed. The fine materials will pass through screen,and the oversize materials will be discarded at the end of the screw shaft. It is especially suitable for screening resin powder (PVC, epoxy), glass beads, quartz sand, light calcium carbonate, aluminium hydroxide and the like powder materials.

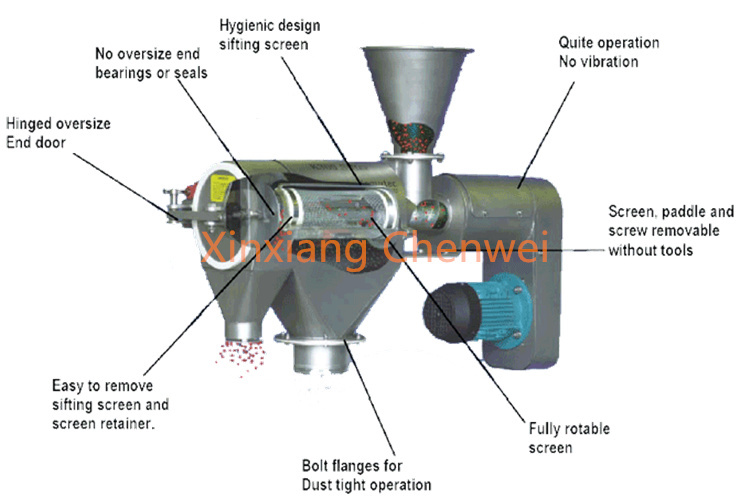

Features of Centrifugal Separator :

a non-vibratory screening machine

No oversize end bearings or seals

Hinged oversize end door

Easy to remove sifting screen and screen retainer

Hygienic design sifting screen

Easy to inspect and/or clean

No tools required for screen, paddle and screw removal

Fully rotatable screen for in-situ inspection

Range of different screen options including; nylon, woven wire and wedge wire

Technical parameter of Centrifugal Separator

| Model | Screen cage size mm (diameter*length) | Screen material | Application |

| BL 25-65 | 250*650 | Stainless steel or Q235 | 325mesh below |

| BL 30-100 | 300*1000 | Stainless steel or Q235 | 325mesh below |

| BL 40-120 | 400*1200 | Stainless steel or Q235 | 325mesh below |

| BL 50-130 | 500*1300 | Stainless steel or Q235 | 325mesh below |

| BL 65-185 | 650*1850 | Stainless steel or Q235 | 325mesh below |

This specification is just for your reference.Other machine size required by you will be accept.

Detailed Applications of Centrifugal Separator

:

- Food Industries: starch, spices, seasonings, milk powder,egg powder, rice flour, wheat flour, beans powder, food additives etc.

- Chemical Industries: fertilizer, detergent powder, talcum powder, dyestuff, rubber, resin, pigment, cosmetic, coatings, PVC powder, CPE powder etc.

Product picture

Different kinds of machine model

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size(length & angle for conveying series) & ideal capacity for proper type, granularity distribution is recommended. product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of DZJX for most of our customers at home or abroad. With our experienced quality control team, we are trying to offer most of our customers the product with bset quality. However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China, China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

As the professional manufacturer of vibrating & transporting equipments since 1987, we are pleased to offer you the best product in a competitive price.

Quotation of vibrating equipments in other type is also available, please feel free to contact us if you have any request.

China

China