100tpd 200tpd, 300tpd super maize meal/maize importers in dubai/degirmen yellow maize exporter

Feature :

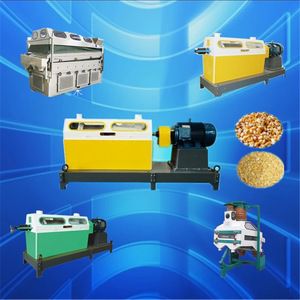

Our Maize corn mill machine using dry peeling and degermingh technology,it can produce different sizes of corn grits and flour at the same time .Corn grits size can be customized as per customer's need in order to meet various needs such as brewery,snack food,glucose,and sugarhouse,Thanks for the dry peeling and degerming technology,husks and germs collected at the end don't need to be dried before used for animal feed.

Complete set maize milling machine can produce low fat corn grits,corn germ,corn flour and corn peel with different size at the same time .The throughput of the set varies from 30tons to 200 tons per 24 hours.The whole assembly line consists of grain cleaning ,maize peeling .maize milling and maize flour packing parts.

Final products parameter

| 100ton maize flour processing line |

| Specification: |

| 1.Production capacity: 100t/24h. |

| 2.Products variety: 1) Maize fine flour ,all 2) Maize germ ;3)Maize bran;4) Fodder flour. |

| 3.per centum: |

| 1)Maize flour: 75~78% |

| 2)Maize germ:7-10% |

| 3)Maize bran and Fodder flour: 13-18% |

| 4.Workshop (L×W×H): 32×9×10m. |

| 5.Power supply: About 260kW. |

| 6.Container:40’×4. |

Final products | Output yield | Fat content | Size |

Corn grits | 45-55% | <0.89% | Mesh 8-40 |

Corn flour /corn meal | 20-30% | <1.5% | Mesh 50-801 |

Animal feed/maize peel | 25% | High | Norma |

1.Sand content<=0.002%

2.Metal content<= 0.003%

3.Water content :13.5-14.5%

4.Color and smell:regula

|

50TPD Maize Flour Mill Parameter

Complete Flour Milling Machine Line including Clean, Proportion, Embryo Removal, Milling, Packing.

Various Final Products: Low fat Maize Flour /Meal, Optional Maize Grits, Bran&Coarse Folder.

| ||||||||||||||||

| |||||||||||||||||

|  |

| |||||||||||||||

Maize Clean & Proportion Section

Various Clean Machine to remove impurities mixed in the maize conditioning Maize for further milling

| Roller Milling Section

Modern roller milling machine and square sifter to grinding and sifting maize flakes into average size and separate bran / germ to get fine low fat maize flour | Packing Section

Auto weighing Packing Scale to realize the weighing, filling, packing in one time automaticly into different size , 5kg, 10kg, 15kg, 20kg,25kg,50 kg. | |||||||||||||||

| |||||||||||||||||

Diamond Grain Machine is a professional flour mill group in food and grain processing equipment. Our business scope covers the Wheat Flour Milling Plant, Maize Flour Milling Plant,steel grain silos.we can make turn-key project to save you time and investment. Our machine has been exported to more than twenty countries, such as Indonesia, Vietnam, Ethiopia, Kenya, Ghana, Uganda, Zimbabwe etc. | |||||||||||||||||

| |||||||||||||||||

|

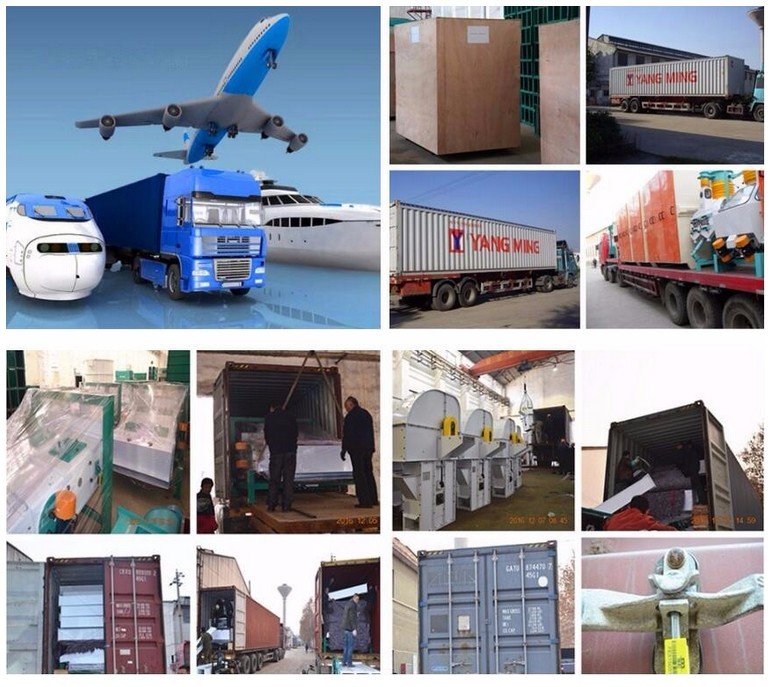

Packaging Details:

1. The machine will be packed with the protect film inner and water-proof outside.2. If the machine less than a container, wooden case packing is necessary.

3. The machine is fixed by steel roper in the container.

4. Others to make sure the machine is in good condition when arrived the destination.

Shipping Detail:

1, Arrange the machine within 30 days after your order be confirmed and received your deposit..

2, Arrange the shipment within 10 days after we received your full payments.

Why buying the Maize mill, maize roller mill from our factory?

1. Aim to do long-term business with you. Do best pre-sale,Emphasized after-sale service.2. Over-sea service center available, 24h after-sale Door to Door service:

Lusaka Zambia,Kinshasa RD congo,Addis Ababa Ethiopia,Multan Pakistan

Durban South Africa,New Delhi India

3. Client good feedback,first buy the small capacity or middle capacity,normally after 2years buy the bigger capacity.

• Egypt client 2007buy the 60T/24h milling machine,2014 buy the 200T/24h milling machine

• Brazil client 2009 buy the 80T/24h milling machine,2014 buy the 250T/24h milling machine

• Zambia client 2013 buy the 50T/24h milling machine,2015 buy another 50T/24h milling machine

4. Engineers with much experience oversea for guidance ,installation,commissioning and testing the machines.

5. Warranty: 36 Months.

1. Q: Which kind of four mill we can manufacture? A: Wheat flour mill and maize (corn) flour mill.

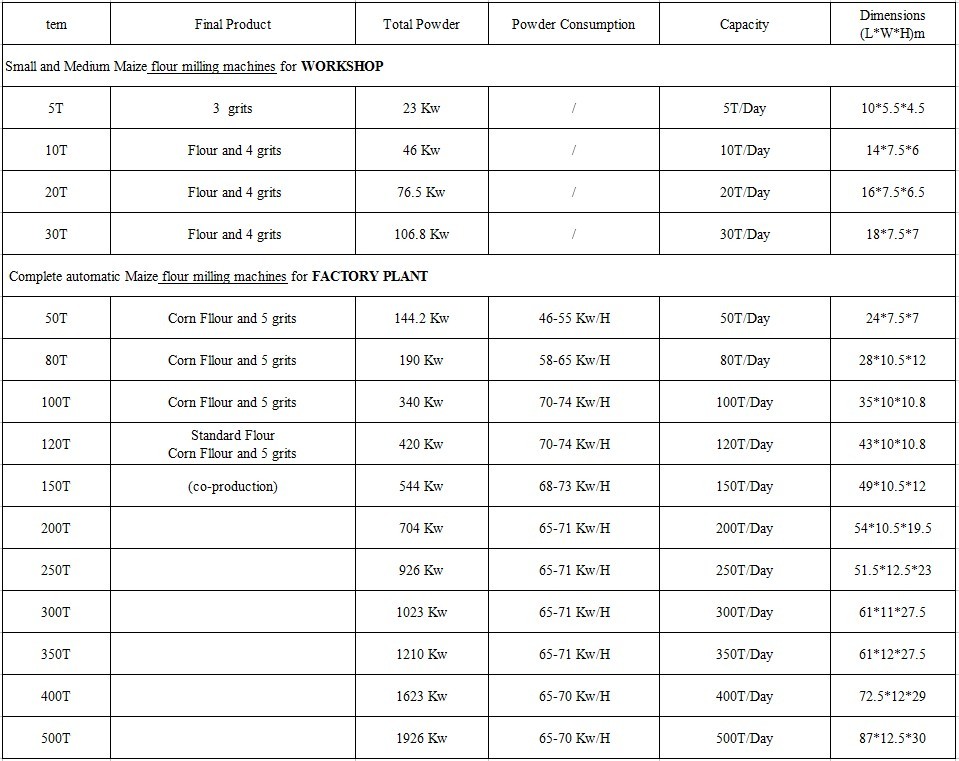

2. Q: Production capacityA: 5-500ton per 24hours.3. Q: Which kind of raw wheat the machine can process?A: Durum wheat, hard wheat, soft wheat.

4. Q: The end products to get from wheat flour mill?A: Kinds of wheat flour, semolina, bran etc.

5. Q: The end products to get from maize flour mill?A: Maize flour, maize grits, maize germ, bran etc.

6. Q: After-sale service?A: We will send professional technicians to your site, they will be responsible for the installation, test running, and training local operators.

China

China