Membrane filter press

Our factory:

Jincheng® has been a leader in liquid/solid separation equipment design and manufacturing for 20 years, meeting the needs of both industrial and municipal clients. Our equipments operate worldwide in evergrowing range of process and wastewater applications. Our customers come from many different countries, like Australia, Iran, India, South Korea, etc.

Products details:

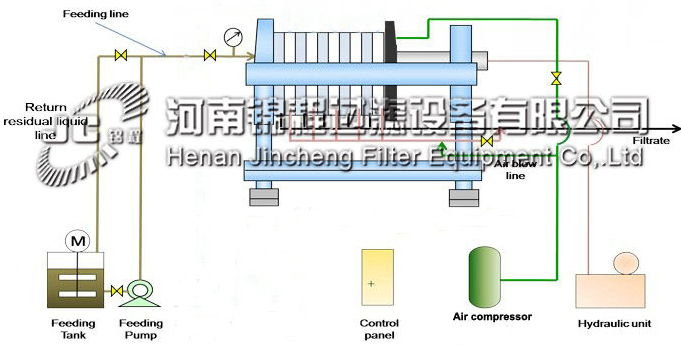

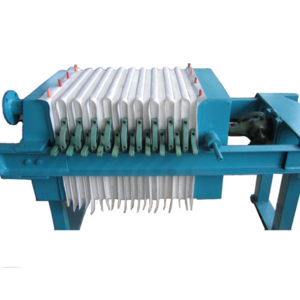

Membrane filter press is composed of Membrane plate and chamber filter plate is arranged filter chamber, under the pressure of transporting pump,the slurry is sent to each sealed filter chamber by the feeding pump with pressure, going into filter plates and filter cloths. The clean water will be filtered out from the filter plate water outlet by the filter cloth, but the solid is kept in the chambers

when the solid form cake, access to the inner diaphragm of high pressure water and air to filter indoor solid fully squeezed,reduce the moisture content.

Working principle

Membrane filter press consists of membrane plate and filter chamber made of ordered filter plates. The slurry materials are sent to filter chamber by the pressure of feeding pump and then go into filtrating media (filter cloth) to separate solid and liquid in slurry material. When solid in slurry material becomes cake shape, air is sent to membrane to fully squeeze the solid to reduce moisture content.

Application:

It is widely applied in many fields such as coal washing industry, petroleum industry, chemical industry, ceramic industry, pharmacy , food industry, textile industry, printing and dyeing industry, paper making industry, waste water treatment industry etc

Advantages

1 Good dehydrating effect

2High efficiency

3Simple structure

4Low moisture content

5Easy to manipulate

6Long service life

6Long service life

Composed:

Membrane filter press including frame,filter plate,filter cloth,hydraulic station,electronic control box

1.The frame is made of high quality carbon steel Q235,beams with rectangular tube seamless welding,special framede formation,strong and durable.

2.Hydraulic pressure station by ABB motot,stable operation and simple maintenance,the piston is made up of 45#steel surface after special processing to get higher high hardness.

3.Electronic control box adopts siemens electrical original,can relize automatically closed,open automatically,automatic voltage regulator,and trouble-free operation.

4.Motor:Motor is ABB product , and has smooth and reliable operation, low power consumption.

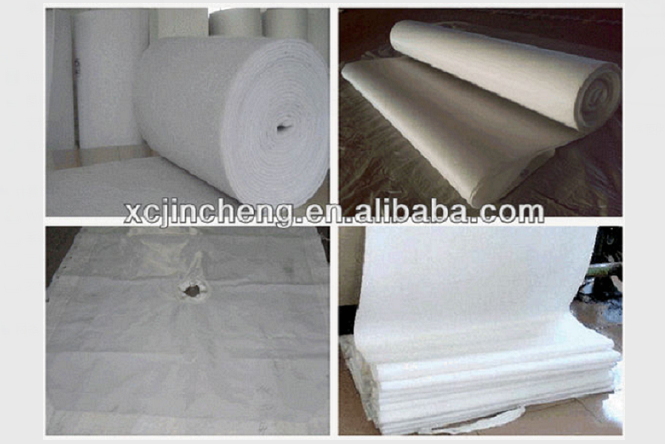

5.The filter cloth,material ofpolyester,non-toxic,odourless,laboratoty 60mpa compressive strength,high temperature resisitant,oil resisitant,resistant to decay.acid and alkali resisitant.

6.Special faucet with polypropylene materials,quick opening type die forming,strong and durable high temperature resisitance,strong acid and alkaline.

Package&Shipping:

Our certificates& Working cases:

Service:

Our goal is to add value to your business and contribute to your success:

1.When you come to visit our factory, we will be there to meet you.

2. We will customize your favorite products according to your requirements.

3.To provide you with the best selling point, to help you improve sales.

4.According to the views of buyers to continuously improve products, and you create a better future.

5.You get fast delivery

6.You get first rate technical care

7.You get the most from your investment.

8.Technical Support:

24*7 hotline service

9.Strict product inspection before delivery

10.Supply the professional technology support online

China

China