LPG-5 Mini Spray Dryer is a special equipment and is suitable for drying emulsion, suspending liquid, liquor and so on. Particularly it has unique advantage for drying polymers and resins; dyestuff and pigment; ceramics, glass; derust agent; pesticide; carbohydrate, dairy products; detergent and surfactant; fertilizer, organic compound, inorganic compound and so on

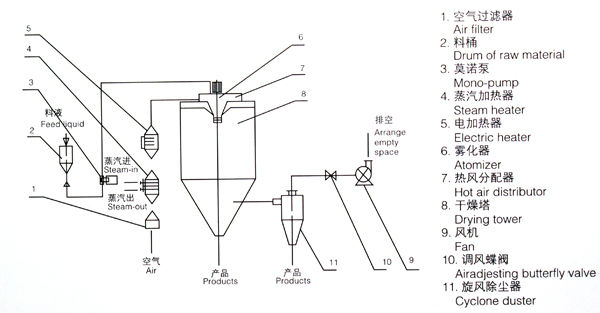

Working Principle :

Air is turned into hot air through air filter and heater into hot air distributor at the top of dry chamber and then enters into dry chamber spirally and evenly, At the sametime liquid of raw material is sent to centrifugally tomizer at the top of dry chamber pumped by pump through filter, In which liquid of raw material atomizes ting droplets. Air and liquid of raw material flows and contacts each other fully. The moisture vaporizes rapidly. Liquid of raw material is dried into finished product in a short time. Tile finished product is discharged through cyclone separator at the bottom of drier. The wasted air is exhausted through fan.

Features:

Its dry speed is very quick. In general, it needs 5~15 seconds. It has feature of momentary dry.

Because raw material can be dried momentarily. Especially, it is suitable for drying thermal sensitive raw materials. It can maintain color, smell and smell of raw material.

Its operation is stable and simple. Its regulation and control is very convenient. It is easy to realize continuous operation.

The distribution, fluidity and solubility of product are good.

Sketch of Flow Chart

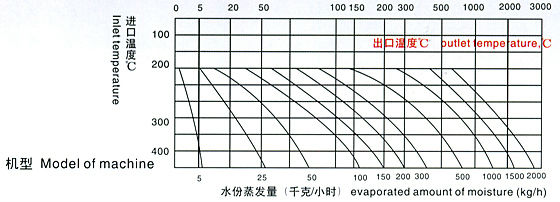

Curve of Moisture Evaporation

TECHNICAL PARAMETERS:

| Model | LPG-5 | LPG-25 | LPG-50 | LPG-150 | LPG-250~5000 |

|---|---|---|---|---|---|

| Inlet temperature | Automatic control140~350°C | Automatic control140~350°C | Automatic control140~350°C | Automatic control140~350°C | Automatic control140~350°C |

| outlet temperature | 80-90°C | 80-90°C | 80-90°C | 80-90°C | 80-90°C |

| Max evaporated amount of moisture | 5kg/h | 25kg/h | 50kg/h | 150kg/h | 250~5000kg/h |

| Drving from of centrifugal nozzle | Compressed airdrive | Mechanical drive | Mechanical drive | Mechanical drive | Mechanical drive |

| Revolution | 25000rpm | 18000rpm | 18000rpm | 15000rpm | 8000~15000rpm |

| Diameter of atomizing disk | 50mm | 120mm | 120mm | 150mm | 180~240mm |

| Heat source | Electricity | Steam+ electricity | Steam+electricity, oilfuel,hotairfurnace | Steam+electricity, oilfuel,hotairfurnace | Steam+electricity, oilfuel,hotairfurnace |

| Max.power of electric heater | 9kw | 36kw | 72kw | 99kw | Affirm it in accordance witth practical conditions |

| Overall dimension | 1.8*.93*2.2mm | 3*2.7*4.26mm | 3.5*3.5*4.8mm | 5.5*4*7mm | Affirm it in accordance witthpractical conditions |

| Recovery rate of dry powder | >95% | >95% | >95% | >95% | >95% |

Note:the evaporated amount o fmoisture is reated to charatcteristics of raw material an inlet and outlet temperature of hot air. When oulet temperature is 90, its curve of moisture evaporation is shown in above Fig.(for reference when you choose Model). With renew of products unceasingly, the relevant parameters will be changed, don't announce is advance, pardon!)

China

China