MVR Rising Film Evaporator

Application

The MVR circulation evaporator is suitable for evaporation of products insensitive to high temperatures when high evaporation is required. It is suitable for evaporation of products that are easy to crust and non-Newtonian fluids whose apparent viscosity can be reduced when flowing at high speed. With the separate boiling chamber and top searator, it is suitable for vacuum or positive pressure evaporation in such industries as food, pharmacy, chemical industry, biological engineering, environmental protection engineering, waste liquid recovery, etc.

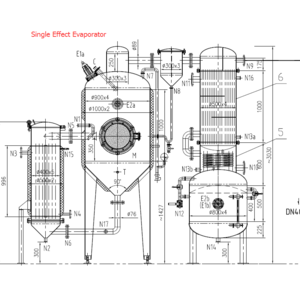

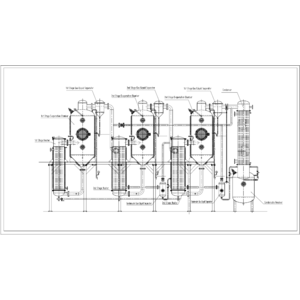

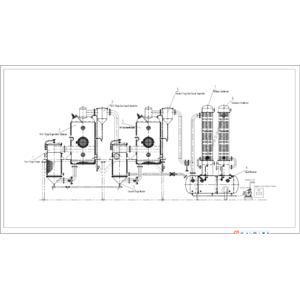

System composition

It is composed of the virtical evaporation heater, gas-liquid separator, non-condensable gas condenser, small flow forced circulation pump, discharging pump, vacuum and drainage system, branch cylinder, operation platform, electric control cabinet, valve, pipe, etc.

Main feature

1. As the latent heat of secondary steam is 100% reused, the use of fresh steam is throughly avoided, so that energy consumption is greatly reduced.

2. As the circulation cooling water is canceled, the problems of water concumption, power consumption and high maintenance costs due to the cooling tower are greatly reduced.

3. The vacuum pump can be used for heat sensitive materials and evaporation can be carried out under vacuum that is near to absolute pressure, so that low temperature evaporation at a minimum temperature of 30℃ is realized.

4. Simple process control and automation. As liquid retntion is low, the falling film evaporation can act quickly according to the changes in vacuum degree, feeding volume, concentration, temperature, etc. This is the basic condition for obtaining products of stable quality.

5. The handling capacity reaches 150t/h. It takes relatively small floor space with compact structure and stable running.

Main Parameters

| 3T/H Evaporation Capacity | ||||

| Equipment | MVR Rising Film Evaporator | Traditional Double Effect Rising Film Evaporator | ||

| Machenical Compressor | 70kw/h | 56.00RMB | ||

| Pump | 6kw/h | 4.80RMB | 11kw/h | 8.80RMB |

| Okw/h | 0RMB | 1800kg/h | 360.00RMB | |

| Cooling Water | 0 | 4m³/h | ||

| Cost/h | 60.80RMB | 368.80RMB | ||

| Cost/t | 20.23RMB | 122.90RMB | ||

| Cost/10thousand t | 202,3000.00RMB | 1,229,000.00RMB |

Amount Saving per 10thousand ton: 1,022,700 RMB

Pcaking: Standard packing

Wooden case is avaliable for MVR rising film evaporator

Delivery: 1-45 days after the deposit confirmed

User demands analysis

Engineering design

Product manufacturing

Automatic control integration

Vertification service

Engineers are avaliable to go abroad to help installation.

Click here to see more products

Click here to learn more about us

Click here to contact us

========↓ ↓ ↓ keep moving down, more surprises await! ↓ ↓ ↓ ========

Here is a brief on us:

- Since 1998, with 17 years of experience

- 3 factories totally covered 40,000+sq.m.

- Annually sales $31.5million, still keeps growing.

- 30+ R&D, 200+ employees professional service.

- Leader of this industry in nationwide.

| Q: Are you manufacturer or trading company? |

| A: TANLET is a professional manufacturer. |

| Q: Where is your factory located? |

| A: All of our three factories are located in Wenzhou, Zhejiang, China. 1 hour flight to Shanghai, 2 hours to Guangzhou, 2.5 hours to Beijing. |

| Q: What is your business scope? |

| A: Chinese Herbal, Western Medicine, Food, Beverage, Dairy and Beer, etc. |

| Q: How could we confirm the details of the products? |

| A: TANLET will provide all the drawings for you to confirm. |

| Q: Will you charge us for drafting if we have special requests? |

| A: No, we will not. Free of charge to make a draft or offer. ODM |

| Q: How long the warranty will be? |

| A: 1 Year warranty |

| Q: How about the installation? And what if the machine goes down? |

| A: Yes, we will do that. There are two options |

| a. We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. |

| b. On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on you side. |

| Q: Do you take L/C? |

| A: Yes, we accept Western Union, T/T and irrevocable L/C payable |

| Q: Can we become your distributor in our country? |

| A: Yes, we very welcome you! More details will be discussed if you are interested in being our agent. |

China

China