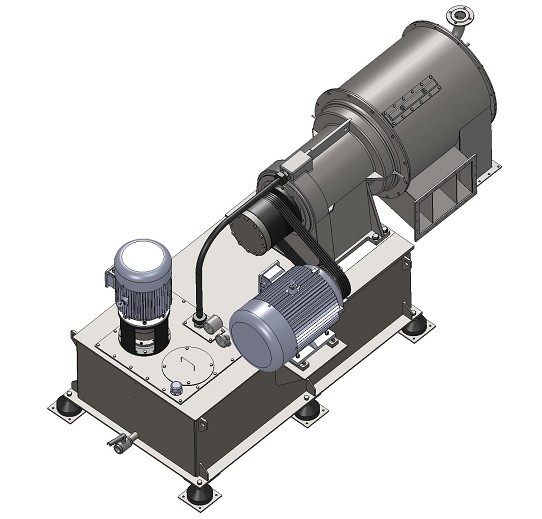

HR double stage piston pushing centrifugal separator

HR centrifugal separator has the traditional advantages of continuous working, high capacity, low consumption, no peakload, compact structure, fast drying, good corrosion resistance, stably running, small vibration, hard broken, residue can be washed, and the connecting part are made of SS304 or SS316L, the corrosion resistance is well.

Typical material: Sodium chloride, sodium dichromate, ammonium sulfate, boric acid, acetate, nitrocellulose, PVC, potassium chloride, potassium sulfate, potassium carbonate, phosphate, paranitroaniline, sodium hyposulphite, baking soda, vacuum salt, ammonium bicarbonate, ammonium chloride, ammonium sulfate, sodium sulfate (glauber's salt), urea, boric acid, borax, potassium sulfate, manganese sulfate, ferrous sulfate, potassium chlorate, coal, sodium bicarbonate, sodium carbonate, sodium chloride, sodium cyanide, nickel sulfate, nitrocellulose, oxalic acid, phosphate, sea salt, "junjun methyl cellulose, plastic, ABS, resin, etc.

Significant character

Using new structure, the designed is more reliable, advanced material distribution method, high speed and pushing times, smooth and flat milling plate mesh, reasonable process data can guarantee high capacity.

High speed brings high separation factor, the fully digging-up process from 1 stage drun to 2 stage drum, make the moisture lower.

When there's a requirement on purity of solid product, the machine can make it effectively washed, if needed, washing liquid and mother liquid can be discharged separately.

The dense homogeneous clearance of milling plate mesh, higher filtering cake can intercept lots of small crystal, can reduce the solid recovery rate.

The precise design, elaborate choosing and manufating, make the machine working long time without fault.

High-precision clearance and high trepanning rate of milling plate mesh, makes the centrifugal separator more usage.

China

China