High end thin film evaporator for sale price

What is Short Path (Molecular) Distillation?

Short Path (Molecular) Distillation is a special liquid-liquid separation technology, which is different from the traditional distillation by boiling point difference separation principle, but by different substances molecular movement of the average free path difference to achieve separation.

Advantages of the Short Path (Molecular) Distillation

Molecular distillation is considered as the safest mode of separation and to purify the thermally unstable molecules and related compounds with low volatility and elevated boiling point. The process distinguishes the short residence time in the zone of the molecular evaporator exposed to heat and low operating temperature due to vacuum in the space of distillation.

Application

Molecular Distillation is applied for separation of high boiling point, heat-sensitive and readily oxidizable materials.

Molecular Distillation is applied for creating a high value clear distillate from Plant Oil Concentrates, for example, refine hemp concentrates into a golden clear distillate that can be infused into a variety of edible products or fine oils to be used in vape cartridges or other products.

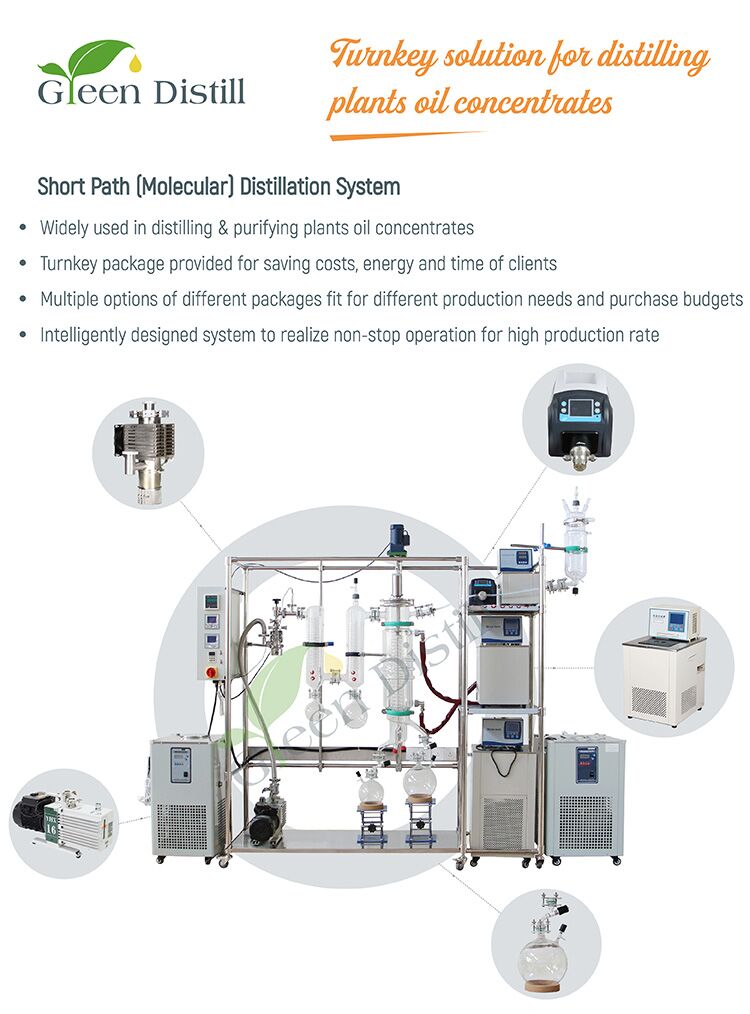

Our Short Path (Molecular) Distillation System (YMD series)

Taking advantage of molecular distillation working principle, our YMD series Short Path (Molecular) Distillation System is a high efficient apparatus for distillation of plant oil concentrates like, to get high grade chemical concentrates.

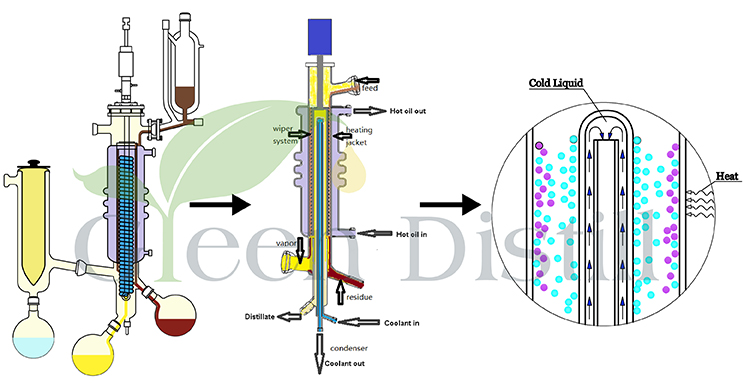

Working Process

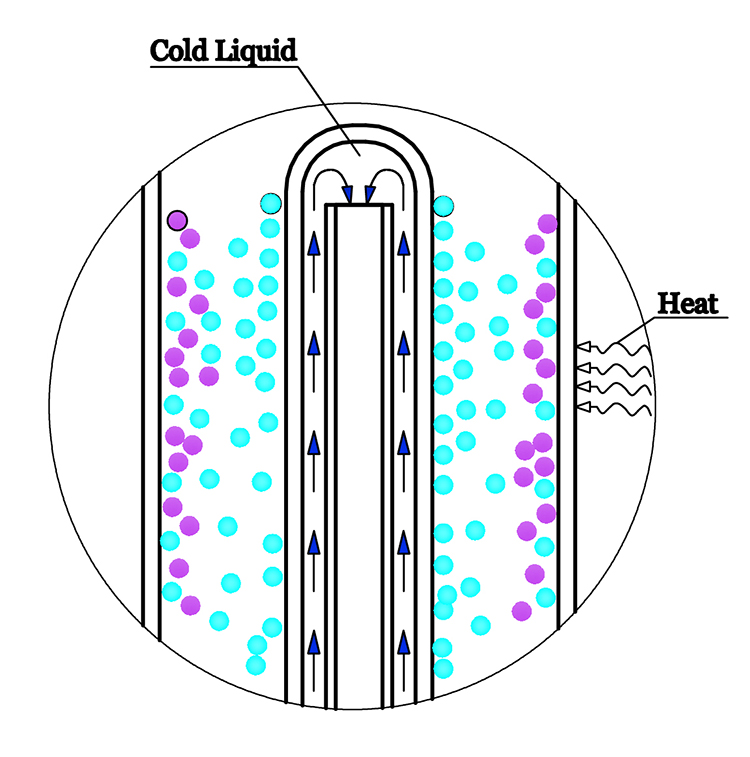

Feed material is delivered from a feed flask into the main jacketed evaporator, having heating from the jacket, and a diagonally slotted wiper mechanism forcing liquid around and downward in a thin film on the inside. In the center of the body is a closely positioned internal condenser, providing a short path for vapor molecules traveling from the heated surface to the condenser surface.

During the journey downward, lighter (lower boiling point) fractions of the liquid begin to vaporize, move to the internal condenser and condense, falling down as a liquid into a well that captures and separates the distilled liquid which flows into the Distillate receiving flask. Heavier residue material (like chlorophyll, salts, sugars, heavy wax fractions) does not evaporate and instead travels the length of the main evaporator body and flows into the Residue receiving flask.

GREEN DISTILL is now offering turnkey packages for short path molecular distillation units.

Features

l Short residence time (separation is finished in seconds, instead of hours.).

l Low operating pressures to 0.1Pa (100Pa=1mba). The very low operating pressure ensures very low distillation temperature and therefore a very gentle distillation is possible.

l Jacket design for efficient heating & excellent heat preservation

l Made of high borosilicate glass 3.3 with great air tightness, easy for viewing evaporation and separation process

l Continuous distillation process

l Low distillation temperature

l High evaporation rates

l Wide choice of models ( Diameter: 60mm, 80mm, 100mm, 150mm and 200mm), fit for clients at starting point, pilot production or scale production. Industrial grades (>=200mm) products are available upon request.

l Flexible design as clients’ requirement for glass ware and support frame

l Turkey package which is plug-and-play, technical supports available.

l Multiple options: one standard set and three advanced sets as clients’ production need

Specifications:

Model | YMD-060 | YMD-080 | YMD-100 | YMD-150 | YMD-200 |

Effective evaporation area(m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

Barrel diameter(mm) | 60 | 80 | 100 | 150 | 200 |

Feeding funnel volume(L) | 1 | 1.5 | 2 | 2 | 5 |

Feeding rate(g/hr) | 250-500 | 500-750 | 750-1500 | 1500-3000 | 3000-5000 |

Motor power(W) | 90 | 120 | 120 | 120 | 200 |

Maximum speed(rpm) | 0-500 | ||||

Distillate receiving flask | 1L | 1L | 2L | 3L | 5L |

Recicle receiving flask | 1L | 1L | 2L | 3L | 5L |

Operation temperature | Up to 200℃ | ||||

Voltage | 220V/50-60Hz |

Green Distillation is a high-end brand of Shanghai Yuanhuai Industrial Co., Ltd, Main category of Green Distillation covers Rotary Evaporator, Short Path Distillation equipment, Molecular Distillation System, Chemical Reactors, Vacuum Filtration System read more...

Welcome to visit us!

Welcome to visit us!

China

China