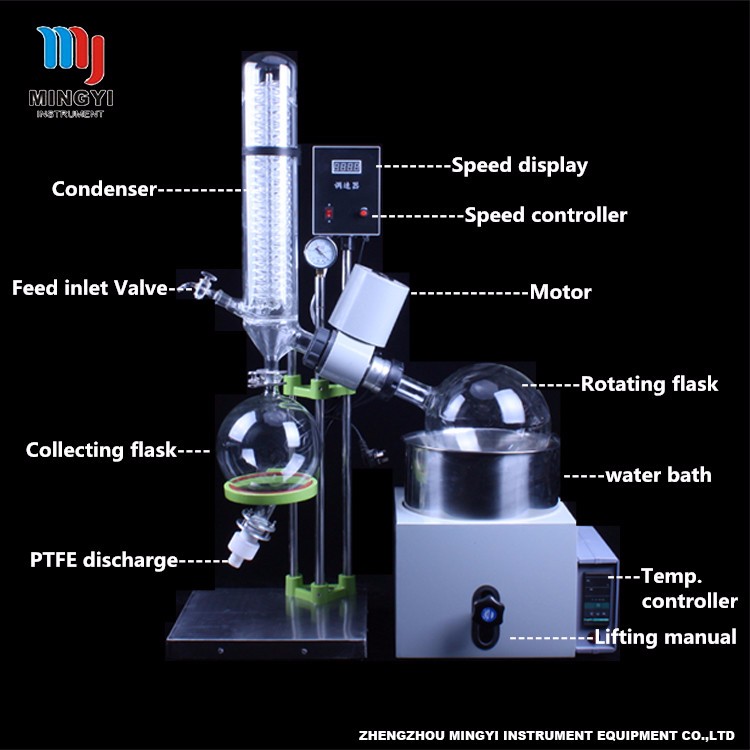

3L digital display multiple effect condenser rotary evaporator

RE-301 rotary evaporator is mainly used in the concentration, crystallization, drying, separation and solvent recovery of pharmaceutical, chemical and biological pharmaceutical industries. Its principle is: under vacuum condition, constant temperature heating makes the rotary bottle rotate at constant speed, and the material forms large area film on the bottle wall, so it can be evaporated efficiently. The solvent evaporation is cooled by the high-efficiency glass condenser and recovered in the collecting bottle, so as to greatly improve the evaporation efficiency. The utility model is especially suitable for concentrating and purifying biological articles with high temperature and easy decomposition and degeneration.

RE-301 rotary evaporator is an indispensable instrument for evaporation, concentration, crystallization, drying, separation and solvent recovery in the research and production of medicine, chemical and biological products. The rotary evaporator is developed under the condition of vacuum and negative pressure, using the principle of constant temperature heating and thin film evaporation. Rotary evaporator with stepless rotation of the glass bottle rotating at a constant speed, the material is formed large area uniform film on the bottle wall, then the intelligent thermostatic water bath for rotating the bottle uniformly heated at high speed under the condition of vacuum evaporation, solvent vapor by high performance glass condenser cooling, recycling in collecting bottle. Rotary evaporator is working under vacuum, and all material contact part adopts the high temperature resistant borosilicate glass and Teflon material, concentrated especially suitable for biological products of high temperature easy decomposition degeneration and purification. The factory set rotary evaporator essence of similar products at home and abroad, in successful practice, has formed 1L,2L, 5L, 10L, 20L, 30L,50L, 100L series, efficient and practical, follow the economic principles of product design, all for the sake of users.

Main Features

1, the main bracket adopts stainless steel + aluminum alloy, the structure is reasonable, and the materials are exquisite.

2, the sealing system adopts PTFE and imported fluorine rubber combination seal, can maintain high vacuum.

3, the vacuum pressure gauge shows real-time vacuum, and the vacuum can reach 0.098Mpa.

4, all glass parts using high borosilicate glass (GG-17), high temperature, corrosion protection.

5, continuous feeding is convenient for customers to use, the valve type feeding pipe is sheathed with tetrafluoroethylene tube.

6, vertical double coil coil condenser, ensure high recovery, additional tubes.

7 、 microcomputer ON-OFF power switch control.

8, bath pot digital display, intelligent constant temperature control, K type sensor fast and accurate delivery temperature.

9, electronic stepless speed regulation (0-120rpm), speed digital display, rotation and torsion settings, easy to operate.

10 fuse safety protection.

11, the pot adopts high quality stainless steel, corrosion resistant and durable.

12, bath pan hand wheel lifting.

Technical Parameters:

Supply voltage: 220V/50HZ (can be customized 110V/60HZ)

Motor power: 40W

Heating power: 2KW

Vacuum: 0.098MPa

Rotary bottle capacity: 3000ml phi 195mm/ Phi 50mm flange

Collect bottle capacity: 2000ml phi 166mm/35# ball mill mouth

Rotation speed: 0-120rpm/min

Range of temperature control: 0-400 DEG C

Temperature control accuracy: + 1

Glass temperature range: -80-250

Bath pan lifting stroke: 0-150 (mm)

Condenser size: Phi 100 * 510H (mm)

Charging valve: 19# standard port

Bath pan size capacity: Phi 255 x 170H (mm), about 8.6L

Shell size: 290L * 296W * 240H (mm)

Board size: 350L * 330W (mm)

Shape size: 660L * 330W * 970H (mm)

Packing size: 1000L * 460W * 450H (mm) wooden box 0.21m

Packing weight: 38KG

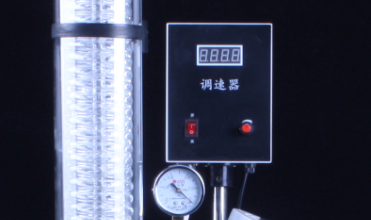

Governor

Electronic stepless speed regulation (0-120rpm), speed digital display, rotation and torsion settings, easy to operate.

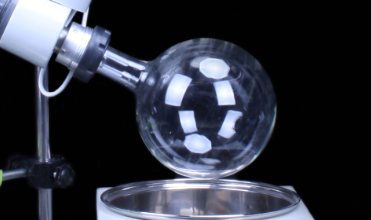

2L collection bottle

All glass parts are made of high borosilicate glass (GG-17), which is resistant to high temperature and corrosion.

Water oil bath control panel

Liquid crystal display temperature, button type regulation of temperature, speed, automatic lifting function.intelligent constant temperature control, Cu50 sensor fast and accurate delivery temperature.Electronic stepless speed regulation (0-120rpm), twist setting, easy to operate.

3L rotary evaporation bottle

5L rotary evaporation bottle, GG17 high temperature resistant glass, temperature range is -80C-250C

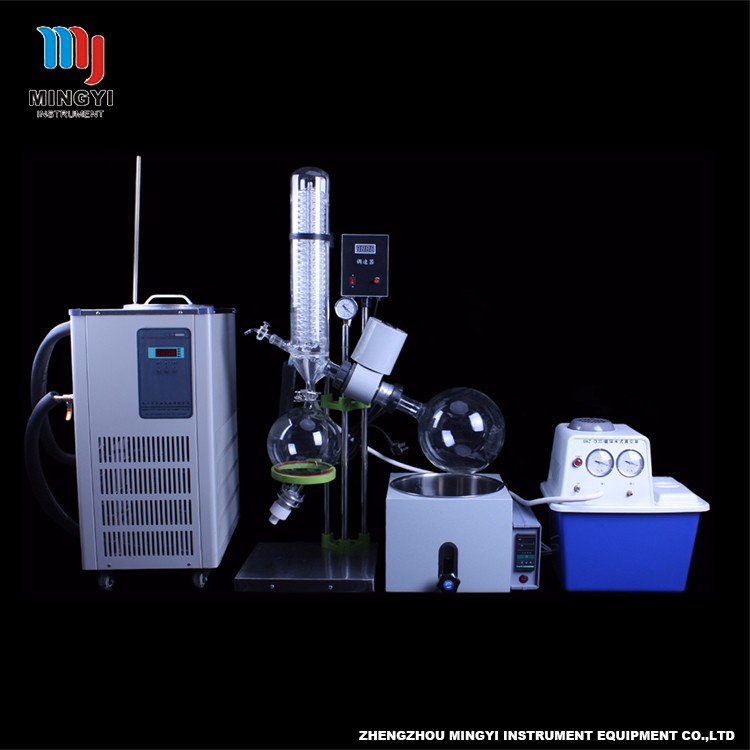

Accessory products

Vacuum pump:Used for negative pressure reaction in rotary evaporator.

Low temperature cooling water circulating pump

RE-301 Rotary evaporator using procedures

1, vacuum: open the vacuum pump, vacuum not, should check whether the bottle mouth sealed, vacuum pump leaks, placed shaft sealing ring is intact, the external vacuum tube in a series of vacuum switch can improve the recovery rate and evaporation rate.

2, feeding: using the system vacuum negative pressure, liquid material can be in the feeding mouth with a hose inhalation rotating bottle, liquid material not more than half of the rotating bottle. The instrument can be continuous feeding, feeding should pay attention to: turn off the vacuum pump; stop heating; to evaporate after the stop, slowly open the pipe cock, in case of backflow.

3, heating: this instrument is equipped with a specially designed water bath pot, you must first add water after the electricity, temperature control scale 0-99 degrees, for reference. Due to the existence of thermal inertia, the actual water temperature is about 2 degrees higher than the set temperature. When used, the setting value can be corrected. For example, you need water temperature 1/3-1/2. Unplug the power plug after use.

4, rotation: open the electronic control box switch, adjust the twist to the appropriate evaporation speed. Attention to avoid boiling water, bath vibration fluctuation.

5. Turn on the cooling water.

6. Recovery solvent: turn off the vacuum pump, turn on the feed switch, deflate, and remove the solvent in the bottle

RE-301 Rotary evaporator maintenance

1, carefully check the instrument before, glass bottle is broken, the interface is consistent, pay attention to gently handle.

2, with soft cloth (can be used instead of paper napkin) wipe each interface, and then apply a little vacuum grease. After using vacuum grease to cover, to prevent dust entering.

3, the interface can not be twisted too tight, should be regularly loose, loose, to avoid long-term locking, causing the connector to bite.

4, first open the power switch, and then let the machine from slow to fast turn, stop when you want to stop the machine in the state, and then switch off.

5, all over the Teflon switch can not be too tight, easy to damage the glass.

6, every time after use must use all kinds of stains, soft cloth to wipe on the surface stains, solvent residual, keep clean.

7, after the stop, unscrew each Teflon switch, long-term static in the working state, will make the Teflon piston deformation.

8, regular cleaning of the sealing ring method is: remove the sealing ring, check whether the shaft product dirt, wipe clean with a soft cloth, then coated with a little vacuum grease, can be re installed, to keep the shaft and seal lubrication.

9, electrical parts must not enter the water, is strictly prohibited to damp.

10, must purchase the original authentic fittings, optional use of other parts of the machine will cause fatal damage.

11, the machine to do any repairs or inspection, we must first cut off the power supply, water. Indicating that this equipment is fragile, please use it carefully when you use it

Pre-Sales Service

* Inquiry and consulting support. 7*24h online,and reply you within 5 min

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.1 year after service,and Lifelong technical support

Production workshop

Workshop production: glass reactor, rotary evaporator and other major glass instruments, as well as other ancillary products.

| Packaging | |

| Size | 1000L*460W*450H(mm) |

| Weight | 38KG |

| Packaging Details | The normal package is wooden box(Size: 1000L*460W*450H(mm)). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

China

China