Chemical industrial vacuum three-stage falling-film evaporator with good price

1. Introduction for falling film evaporator

Falling film evaporator: the material liquid enters from the top of the evaporator and flows downward along the wall of the tube with the action of gravity.

2.Applicable range

The application of evaporation in various materials, especially suitable for not scaling, strong evaporation and heat sensitive materials.

It is widely used for evaporation and concentration of water or organic solvent solution in medicine, food, chemical industry, light industry and so on, and it can be widely used for waste liquid treatment in the above industries. Especially suitable for heat sensitive materials, the equipment for continuous operation under vacuum and low temperature conditions, with high evaporation capacity, energy saving, low operation cost, and can ensure the invariance of materials in the evaporation process.

3.System components

The system consists of evaporator, separator, condenser, vacuum and drainage system, various effective liquid, conveying pump, operation platform, electrical instrument control cabinet, valve and pipeline system.

4.Multi-effect evaporation concentration equipment

The new steam enters the first effect as the heat source, and the2nd steam generated is introduced into the second effect, and is sequentially analogized to connect multiple evaporators together, so as to form a multi effect evaporation system. In the multi effect evaporation system, the latent heat of steam is reused, which can reduce the consumption of heat energy significantly, greatly reduce energy consumption and increase the thermal efficiency.

1).Use the most common evaporation and concentration equipment.

2).With the increase of the number of effective bodies, the more the steam consumption is saved.

3).Although the cost of equipment investment is less, a large amount of steam is caused by a large amount of steam consumption.

4).The crystallizing of concentrated evaporation is suitable for low steam prices.

5.The drawing for the falling film evaporator ( Five effect falling film evaporator )

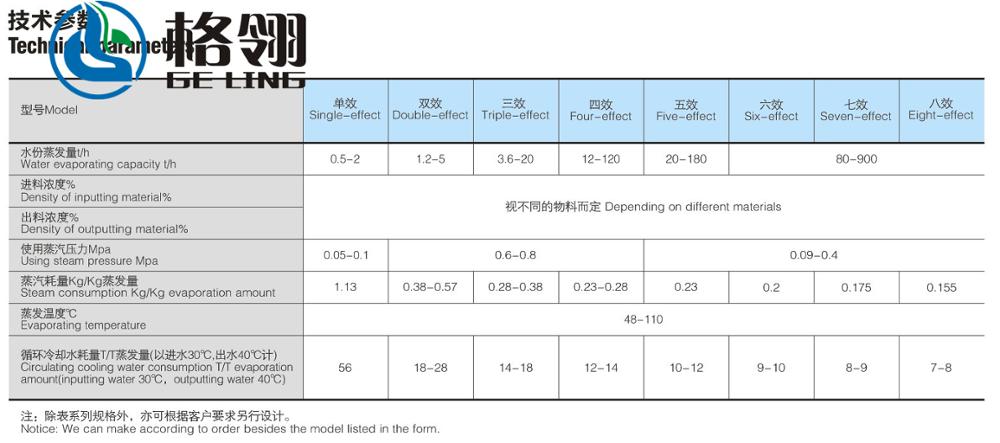

6. Energy Cost for Falling film evaporator

7. Pictures shows for falling film evaporator

Port of loading: Shanghai port /Ningbo Port

China

China