Factory price jet cooker for dead animal rendering equipments

| Production Information |

| Poultry waste reception section

There is a Material Silo For the reception and storage of poultry wast,dead animal. There is a Pre-crushing machine in the middle in function of chopping whole animal caicasses and large pieces with aim of 50mm size piece(easily transported) A Material Pump is at the bottom to transport the marterial to cooker.

|

Cook and Dry Section

Function: Waste raw materials(feathers,animal,fur,sick livestock,animal carcasses) through the process of high temperature and pressure to achieve the effect of sterilization and break down

Features: Big capacity of each batch,the efficiency of sterilization is complete and safe. It could be used to break,cook,sterilization and drying.

|  |

| Oil Press Section

The material from silo are sent to the heated pot by screw conveyor, and then go into the oil press, after oil press, we get the cake with 10-12% oil and fat ,the odor from this section collected by pipeline and is treated together. |

Cooling Section

The cake from cooker is sent to cooling system by screw conveyor(with dust collection), the tempertaure is reduced to ±5℃ room temperature. |  |

| Meal Section

Function: To reduce the size of meal.

Features: 1.Unique crushing chamber to improve the efficiency of grinding. 2.Special rotor design program,and the harmmer sieve gap,which can meet different granularity. |

Packing Section

Automaticly packing the meal.

| |

| Odor treatment section

To seperate solids and liquids entrained in the process vapoures from cooking /drying equipment,by washing of glasses collected from several process points. |

Final Products Tallow: Moisture<1% Meat and Bone Meal: Protein≥65%

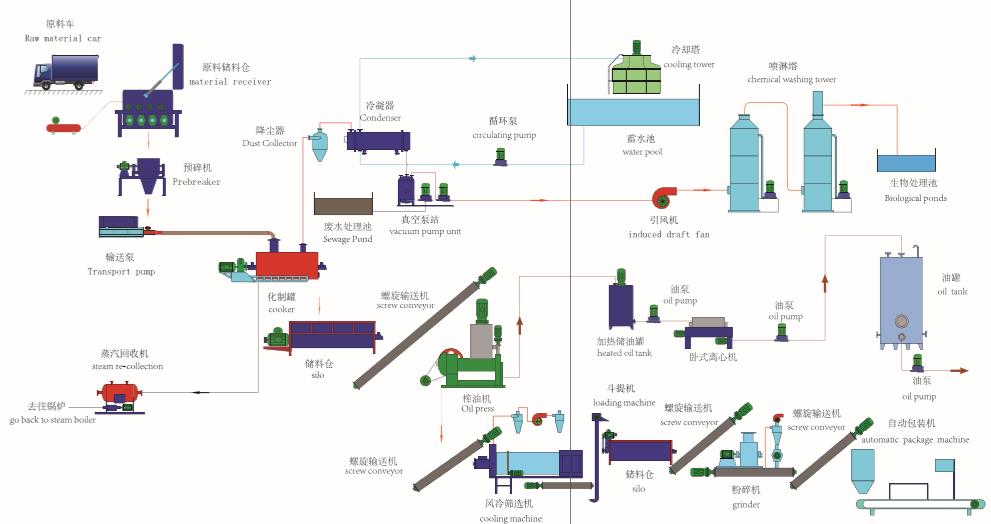

The whole line consists of material buffer bin,conveyor,cooker dryer,grinding,packing and odor treatment system

|  |

| Product Features |

The batch cooker is delivered as a unit ready to install inclusive of all necessary valves, instruments, steam trap system, safety valve, and insulation as standard.

The batch cooker can be supplied with manual or automatic discharge door.

Options:

Automatic moisture control with end point signal.

Automatic process control equipment.

Weighing sensor

The design of the batch cooker complies with GB national standards and each machine is produced,inspected and tested in accordance with GB pressure vessel standard and regulations .

| Applications |

Process Flow

Crusher ----> Cooker ----> Dryer ----> Defatting ----> Cooling ----> Milling ----> Packing

Batch cooker is designed for sterilisation, hydrolysation, and drying of animal by-products.

Batch cooker is one of the most important parts of a dry rendering plant and is manufactured in three standard sizes to suit various plant capacities.Jiansu Sunrise batch cooker can be used for processing of the following animal by-products:

Mixed meat offal and bones

Raw blood

Wet feather

Mixed poultry offal

Notes:

We can design a turnkey production line for our customers,the line including many machines,customer also can choose the one they need depend on their production and the founds,so no matter what requriements you have,we will try our best to with you

If you need more information, please click to contact us!

| Company Information |

COMPANY

PROFILE__

Hebei Chengzhu Machinery Group Co., Ltd was founded in 1990, we specialized in contracting the project of poultry and livestock waste rending plant and slaughterhouse waste, after 20 years development and growth, we have become the company with technology research and development, processing design, product manufacturing, installation and training. Our company has developed a new type of hydrolyzed feather dusting machine, which is based on the advanced technology of European and American countries, and combined with the new generation products developed by our company for many years.

|

COMPANY CERTIFICATE

Products passed ISO 9001

|

|

| Our Service |

Pre-sale Service:

Your inquiry related to equipment or price will be replied within 24 hours.

Well-trained and experienced staff will answer all your inquiries in English of course.

We accept OEM&ODM projects.

We have strong R&D team here to help.

Your business relationship will be confidentional to any third party

After-sale Service:

1 year warranty period, please don't hesitate to contact us if you have any question with the equipment

| Contact Us |

China

China