Machine function:

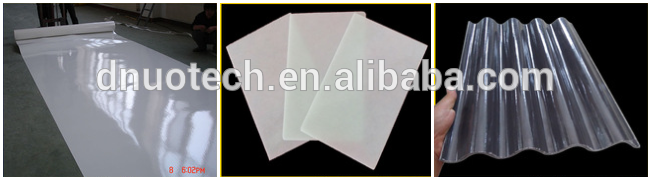

This production line is able to produce lighting sheet, color sheet, common flat sheet or gel coat sheet.

Basic parameter:

Operation staff | 4-8 people |

Production speed | 2-7m/min |

Sheet width | maximum width 1500mm-3200mm |

Wave height | maximum 130mm |

Sheet thickness | 0.4mm-4mm |

Gel coat thickness | 0.2-0.8mm |

Machine main dimension | 67m (L) ×6m (W) ×6m (H) |

Power requirement | 200 KVA |

Power consumption: | Approximately 100kw/h |

Machine characteristics

1. Products width can make on demand.

2. The impregnation table can control temperature independently & accurately. It can adapt to the

outside temperature fast impregnation fast and improve the production speed effectively.

3. Pulse free metering system, accurate metering, and wide flow rate adjustment range.It can add

powder filler.

4. Easy operation based on PLC intellectual control system. Operate by two computers, the production

task and equipment operating data is faster and intuitional. Only short-term training can make operators

complete production independently.

5.Three separate ovens for temperature control, unique temperature control arithmetic makes oven

heating fast, temperature control precise. Which improve quality of products, reduce energy consumption

and shorten the preparing time effectively.

6.Metering control system and Roving chopper speed can be synchronous with the production line.

7.Special cross cutting machine and good synchronization performance make cutting accurately..

8.All the machine parts adopt international standard steel make machine with high stability.

9.System failure can be automatically alarmed and show fault point. Make

maintenance easily.

10. Electric system adopt Siemens brand.

Equipment Display

Hauling system and dust-free cutting device

Heating oven: top doors and side doors can be opened, which is convenient for operators to observe the sheet.

Electic sytem: well-arrangd cables, eay-to-operate panel, and famous brands

Application

We have 16 years of manufacturing experience in FRP continuous forming making machine. We adopt famous brand electronic control elements like Siemens control system. In addition, all the machine parts adopt international standard steel to enable the equipment to reach the long service life and the stable performance.

Until now, our company has occupied more than 60%-70% domestic market with obvious advantage with the machine being exported to the USA, Saudi Arabia, Jordan, India, Indonesia, Malaysia, Vietnam and Azerbaijan etc. We will take part in some big exhibitions like Shanghai Composites Exhibition, Singapore Composites Exhibition, Russia Exhibition to advertise our machine and company.

1. Guarantee for 1 year excluding wear and electrical parts. Extra fee is paid if out of date.

Any damage to the machine caused by improper use will be charged.

2. The equipment is fully test before delivery

3. Free installation, training and commissioning on site to help the operators operate as soon

as possible

4. We will provide wear and electrical parts at an agency price when you need replacement.

If you are interested in our products, please feel free to contact wtih me.

Welcome to contact with us.

Tel: 86 335 856 1678

Modile: 86 157 033 698 79

Skype: 86 157 033 698 79

Tina is expecting for your inquiry!

China

China