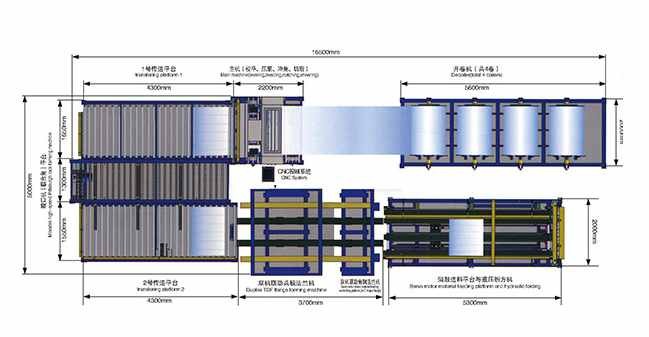

| Model | SADL-5U 1250/1500 |

| Thickness range(mm) | 0.6-1.2 |

| Max-working speed(m/min) | 16 |

| Width(mm) | 1300/1500 |

| Coiler weight(kg) | 6000*4/8000*4 |

| Weight(kg) | 20000/22000 |

| Dimension(mm) | 16000*8000*1300/ 16000*9000*1300 |

Characters

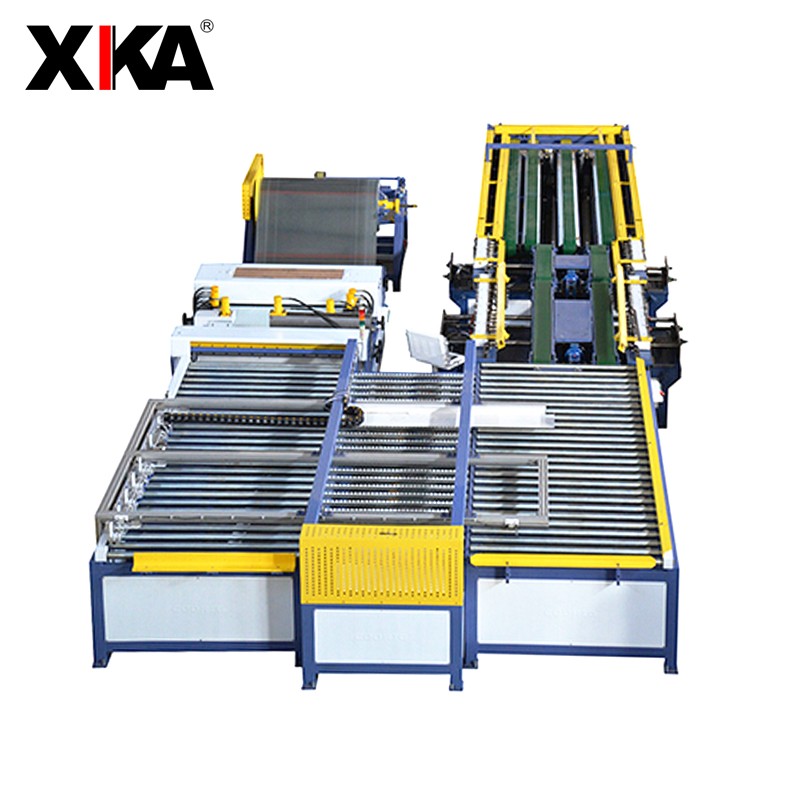

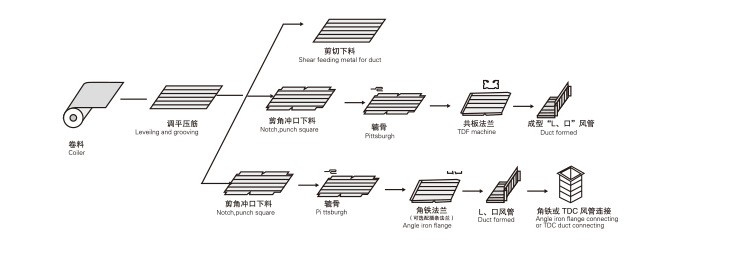

Auto-line V is consists of feeding frame,levelling , grooving roller machine,hydraulic puching square notch equipment,mechanical hand fixed position feeding frame plat,double drive TDF flange former and doulble drive singe hem former,servo feeding plat and TDF hydraulic folder.All systems is controled by computer.The feeding is by servo with precise location.When producing “square”shape duct,the folding is with high precision. The maximum work speed is 16m/min.The diagonal line tolerance is ±0.5mm. The line V can produce 2 kinds of ducts:TDF flange and angle iron flange.It is easy and fast to adjust.

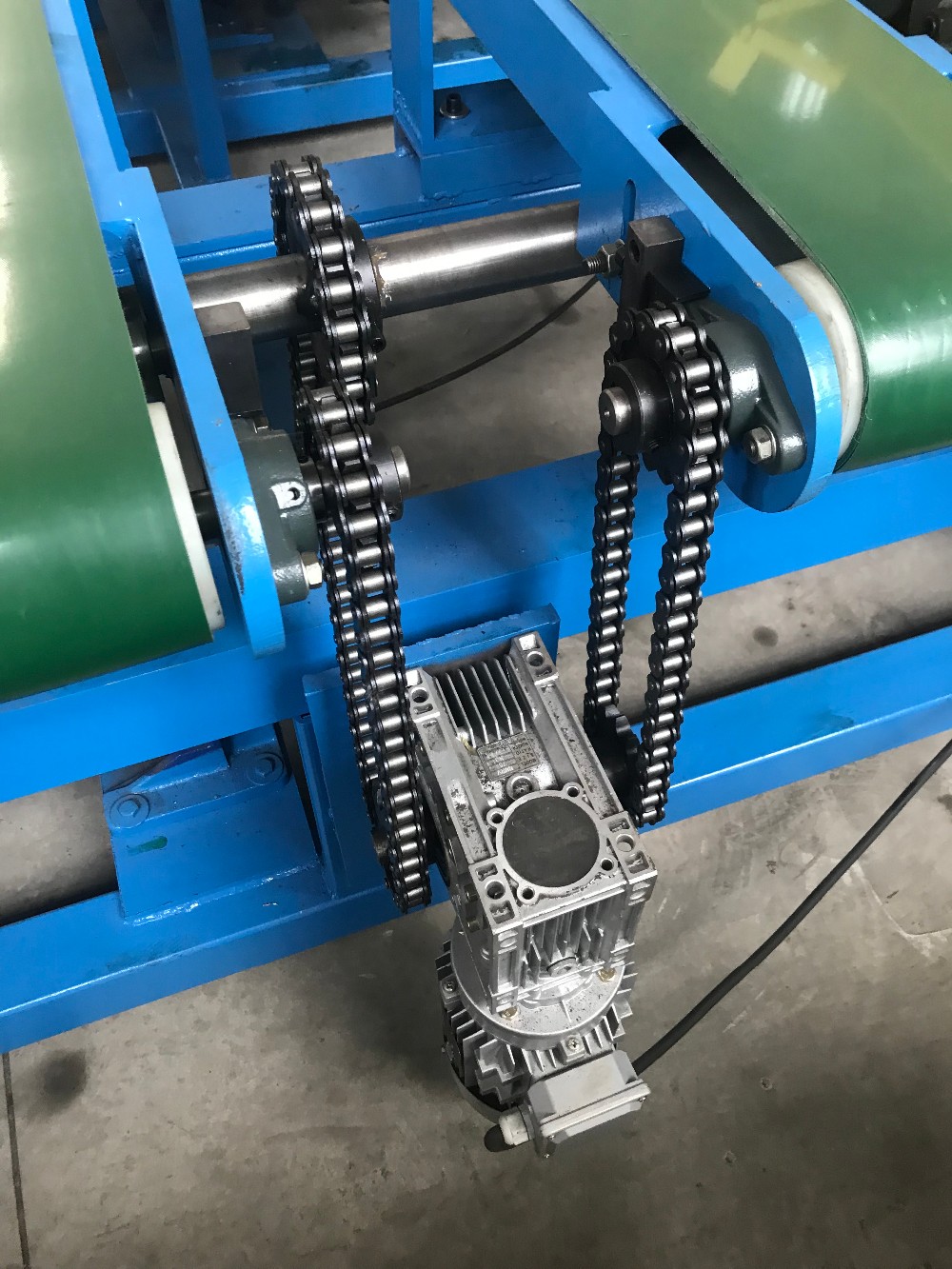

It saves work space,with linear type structure,high effeciency.It can produce“square”shape duct with litte section,the minimum section area of TDF duct is 200×200mm.

Basic parts

1.Two sets of electric feeding frames(can put total four coilers)

2.One set of leveling and grooving device

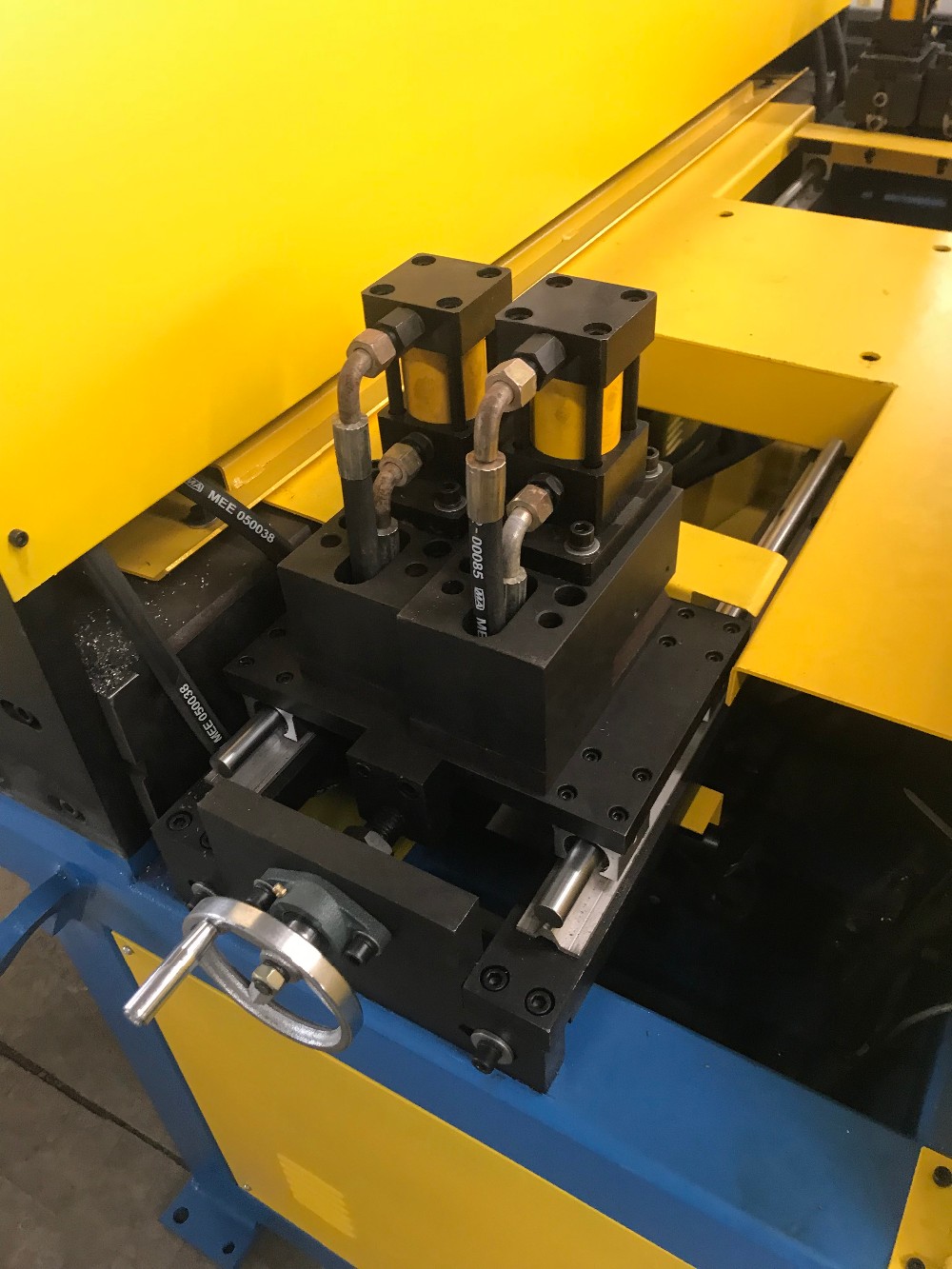

3.One set of holes-punching device for supporting ducts mounting( Customer optional configuration)

4.Punching mounds

5.One set of electric feeding table( the front part)

6.Pittsburgh lock former

7.One set of electric feeding table( the latter part)

8.Duplex angle-iron flange former

9.Duplex TDF flange former

10. TDF hydraulic folder

| Manufacturers : Industrial Concentration Zone, Xinshi Town, Bowang Dist. | |

| Brand : XIKA | |

| Tel: +86-555-6970023 | Fax: +86-555-6970024 |

| Phone:+86-18655522244(WhatsApp) | |

| Email:cnxika◎sina.com | |

| Website: www.cnxika.com |

Payment terms, Usually is T/T 30% deposit in advance,70% balance before delivery.

Warranty time,24 months after sale.

After sale service,providing technical service,replacing the parts freely during warranty not include artificial

damage or damage caused bt improper operation,we can send our engineer to your country if necessary.

Machine moulds and dies can be designed according to customers needs.

China

China