Pneumatic Control Air Freshener Aerosol Filling System

Semi automatic aerosol filling machine consists of three parts: liquid filling, valve fixing, sealing and gas filling, which is designed at one worktable. Using linear pushing bottle system, moving cans automatically.

It is widely used in daily chemical, auto-care, household-care, food and pharmaceutical industry. Filling moisture spray, wax board, carburetor cleaner, air fresher, spray paint, etc

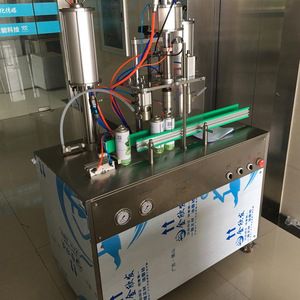

CJXH-1600AT 3 in 1

Aerosol filling machine: liquid filling + sealing + propellant gas filling;

Using linear pushing bottle system, cans moving automatically, with automatically filling mode;

Flexible working mode, easy to operate.

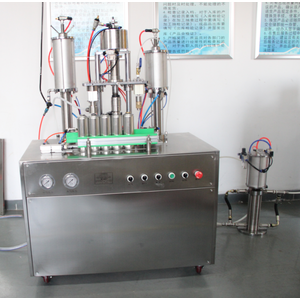

CJXH-1600AT 4 in 1

Aerosol filling machine: liquid filling + Valve fixing+ sealing + propellant gas filling;

Using linear pushing bottle system, cans moving automatically, with automatically filling mode;

Flexible working mode, easy to operate, just one operator needed

CJXH-1600B 3 in 3

Semi automatic aerosol filling machine: liquid filling part, crimping part and gas filling part on three separate working tables;

Easy to operate, three operators needed;

5000-8000cans/day

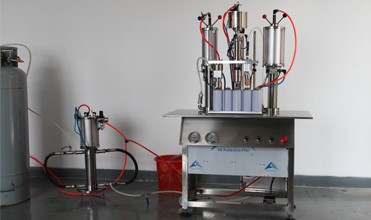

CJXH-1600A 3 in 1

Semi automatic aerosol filling machine: liquid filling part, crimping part and gas filling part on one working table;

It is just 1.0m3, very easy to operate;

Capacity can reach 3000-5000cans/day.

LPG Deodorization Tower

Semi-Automatic Water Bath Equipment

Valve Remove Machine

Enjoy and contact us for further information!

Whatsapp & WeChat: +8618907115569

Check our website

https://cj1995.en.alibaba.com

China

China