220V 380V 0 - 600Hz inverter enclosure PLC electrical inverter control cabinet

Inverter control Cabinet:

CHZIRI Electrical can design different MCC panel according to clients'wiring diagram . Welcome to send inquiry to us .

With the frequency technology become more and more mature, the use of frequency inverter, PLC, digital-analog conversion module, temperature sensor, temperature module and other devices combine to form a closed-loop automatic temperature control system, the system can work smoothly and more stable, More important Its energy-saving reach to as much as 30% or more, can bring good economic benefits.

The frequency inverter control panel adopts the enclosed cabinet structure, adopts the frame skeleton, the surface coating spray, and easy to install the cabinet, the upper end can configure the bus bar . the keypad of frequency inverter leads to the front foot of cabinet and can operate directly, it can set local and remote control or PC/PLC communication control .the inverter control cabinet can display different kinds of function .

Frequency inverter is a dedicated accessory of inverter cabinet ,the variable frequency control the speed and the main technical parameters depends on the specification of built-in inverter and external configuration. Inverter cabinet have big difference according to the use of different application and different functions

According to the needs of the operating conditions, we can install AC input reactor, output reactor, DC reactor, EMI filter, braking unit, breaking resistor, contactor, intermediate relay, thermal relay, PLC, GOT , Electricity meter , cooling fan and ect inside the control cabinet .

According to the system working conditions, we can set a variety of control button and indicators. Such as forward, reverse, motor speed boost, motor speed deceleration, jog forward, jog reverse, manual / automatic, emergency stop, frequency conversion, power frequency, PLC control, touch screen and so on in the front door of the panels .

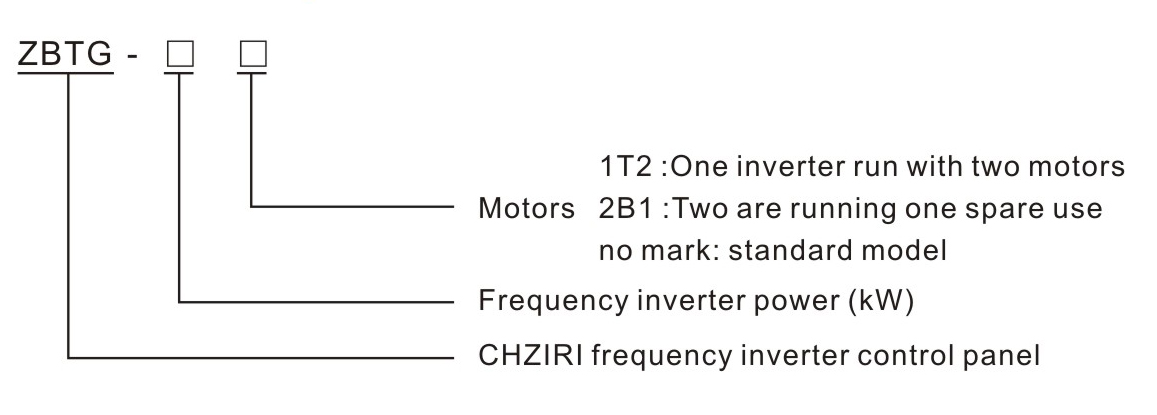

Model description:

Using condition:

Power Supply: Electric supply r, self-connected power network, diesel generator set, 3phase AC 380V , (-10%,+15%),50HZ

Applicable motor: three-phase asynchronous motor, variable frequency motor

Start frequency: can start frequently

Protection class: IP41 or IP20

Environment condition:

Altitude ≤ 2km (used and downgraded if altitude beyond of 2km),

Environment temperature : -25℃~ +40℃

Relative humidity: ≤90%, no condensation

Vibration: ≤0.5G

Applicable Industry:

The frequency converter control panel (VFD electric control panel / electrical control panel) can widely use in metallurgy, chemical industry, petroleum, water supply, mine, building material, electrical motor industry, such as pumps, fans, air compressor, rolling mill, injection molding machine, conveyer belt and other machinery and equipments.

Frequency inverter control panel function:

1.The power switch and protection frequency inverter cabinet l are equipped with low-voltage MCCB which is connected to the power line, in addition to complete and disconnect the circuit, can protect the circuit and VFD short circuit and overload protection . can cut off the power during maintenance .

2.Start and Control function . on the front door of the panel set the inverter start pushbutton .inverter stop pushbutton for the inverter operation control .easy for on-site operation .

3. Frequency (speed) adjustment :

adjust the setting frequency and potentiometer on the front panel, It can easily and convenient to adjust the output frequency of the VFD manually .to control the motor speed.

4. Meters display on the front door of the panel . install the voltmeter,Ammeter,frequency meter and different kinds of indicators .Such as power indication,alarm indication, running indication, working frequency , inverter input voltage, inverter output current, inverter output frequency and monitoring of different working status .

5. Spare working frequency switching . the user can select the inverter cabinet with spare use working frequency switch . when the inverter get failure . can make the motor switch to working frequency power supply according to the automatic control circuit .(you can select manual /automatic mode, When the working frequency start device is more than 15kW . you can use soft starter to realize this function).

6. A variety of control function. According to the system working .it can set a variety of control buttons and indicators on the front door of the panel .such as Forward,Reverse , Motor increase the speed , motor reduce the speed , Jog forward , Jog reverse, manual/automatic, Emergency stop, variable frequency/working frequency ,PLC control, Touch screen .

7. According to the needs of the operating conditions, we can install AC input reactor, output reactor, DC reactor, EMI filter, braking unit, breaking resistor, contactor, intermediate relay, thermal relay, PLC, HMI , Electricity meter , cooling fan and ect inside the control cabinet .

8. Safety protection .Install the VFD in the frequency control panel, can reduce environmental pollution, reduce the risk of electric shock, will have better protective effect.

9. Neat and beautiful appearance. install the VFD in the frequency control panel, have the same size with other low -voltage switchgear .the same color ,to maintain the power distribution facilities and control equipment coordination, neat, beautiful.

Characteristics Analysis:

1. Save energy

Inverter control motor compared with the traditional control of the motor, energy conservation is the most practical significance, you can achieve energy-saving effect.

2.Lower operating cost.

The traditional motor are consists of three parts: initial purchase cost, maintenance cost, and energy cost. The Energy costs account for about 77% of the motor's operating costs. After install the frequency and soft starter start to reduce the impact of the device. The energy costs can be reduced by 44.3%.The maintenance and repair volume also reduced . So the operating costs will be greatly reduced.

3. Extend motor’s life

In addition, the frequency conversion control can reduce the unit start when the current fluctuation, this fluctuation current will affect the power grid and other equipment, the inverter can effectively reduce the peak starting current to a minimum. Starting from 0HZ, the start-up time can be adjusted to reduce the impact on the electrical components and mechanical parts of the motor at start-up, thus enhancing the reliability of the system and prolonging the service life of the motor. In addition, the frequency conversion control can reduce the unit start when the current fluctuation, this fluctuation current will affect the power grid and other equipment, the inverter can effectively reduce the peak starting current to a minimum.

4. Reduce motor’s noise

According to the requirements of the motor operating conditions, the installation of frequency inverter, the motor speed significantly slowed down, so effectively reduce the noise of the motor running.

ZIRI Electrical Technology Co.Ltd.is a Sino-French joint venture engaged in R&D, manufacture, sale. distribution and service of electric drive and control products. Professional and experience supplier of automation solution for multiple field.

The main products includes general –purpose inverters, special –purpose inverters for pump and fan, soft starter, breaking unit and other inverter accessories which has characteristic of advanced technology, complete function, stable running, simple operation, fine energy saving and excellent performance and so on. The products are widely applied to the various industries ,metallurgy, plastic, textile, food, papermaking. drugs manufacture, printing, construction material, cement, oil, chemical industry mining. transmission device ect.

Thanks to the good quality, we respectively obtained ISO9001, CE ,CCC and other certificates

About company 1. low voltage frequency inverter and soft starter manufacturer and exporter.

2. More than 15 years experience and professional devoting the automation control system. we want to be the best to serve our clients.

3. CHZIRI frequency inverter and soft starters are certificated with CE. CHZIRI Electrical passed ISO9001:2008 quality control system.

4.CHZIRI Electrical are near to NINGBO ,SHANGHAI port .The shipping cost will be cheaper.

Q1.Can I get some samples?

A1:Yes, Sample order is available for quality check and market test.

Q2.What’s delivery time?

A2:It usually takes about 3-5 working days for small order and 10-15 days for big order.

Q3.What’s your payment terms?

A3:We usually accept all kinds of payment terms .Such as T/T,L/C, Western Union.PayPal,Cash.

Q4.What’s your warranty terms?

A4:We offer 16 months warranty time.

Q5.Do you have the products in stock?

A5:Depends on your request, We have standard models in stock. Some special products and big order will be newly produced according to your order quantity.

Q6.How does your factory do the quality control?

A6:Quality is priority, we always attach the importance to quality control from the beginning to the end of the production. every product will be fully assembled and carefully tested before packing and shipping.

Q7.Can the inverter connect with computer, PLC?

A7:Yes. All inverters have built-in RS485 port .and support Modbus communication protocol. It’s OK for CHZIRI VFD inverter to connect with computer and PLC. we have software engineer. can program the software for the special function.

Q8.Can you make the inverter and soft starter control A8:boards (control panel )?

Yes. We have a lot of experience to design VFD control panel and soft starter cabinet according to your request. It’s better for you to send us the primary wiring diagram.

Q9.How to be CHZIRI dealer in our country?

A9:CHZIRI Electrical are looking for a reliable dealer who have professional knowledge and good contacts in local market .and we will check his annual sales. As you know .the after sale service are very important. It need professional technician to do service. Most time it not quality problem. It may be application problem. How to set the parameters according to actual application.

Q10.How to deal with after sale service for CHZIRI products ?

A10:If your country have CHZIRI dealer .CHZIRI Partner will offer on site service. If there don’t have distribution in your country. Please contact with our company directly. we will give you solution within 3 working days.

Q11.How can I trust you?

A11:The core of CHZIRI electrical culture is honesty and loyalty.our company has been audited and approved ISO9001, CE, CCC. Assessment report will could be sent to you by e-mail. also, we are the made-in-china’s gold supplier since 2008. Now we have clients all around the world.

China

China