outdoor waterproof double door electrical control cabinet

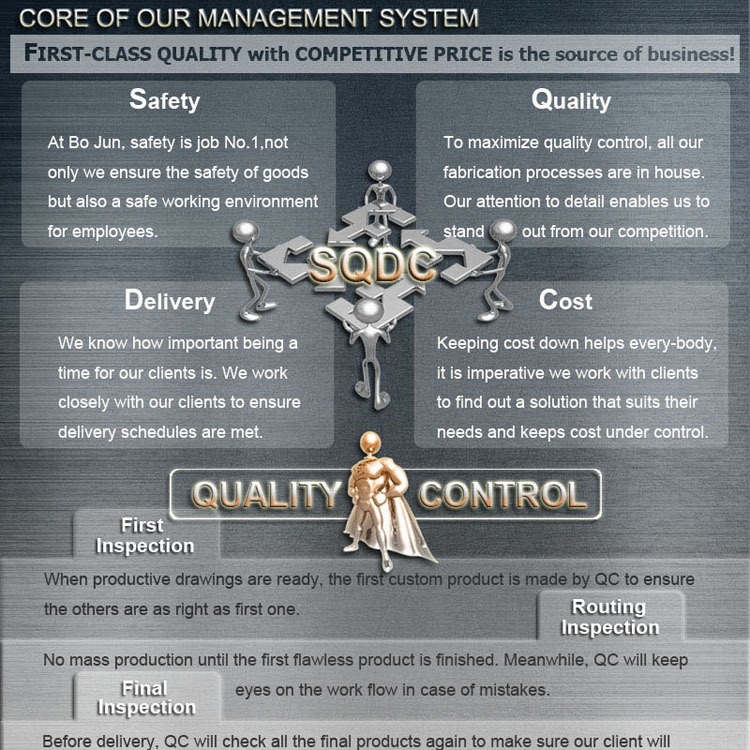

Bojun Precision Sheet Metal specialize in custom sheet metal electrical cabinet fabrication for different kinds of materials with high precision laser cutting, CNC punching, stamping, bending, machining, welding, powder coating and assembly service. As a factory with 5000 square meter workshop and 50 workers , we are able to save cost of labor and shorten production lead time, which enables us to compete with others. "First class quality with competitive price is the source of business." is our motto.

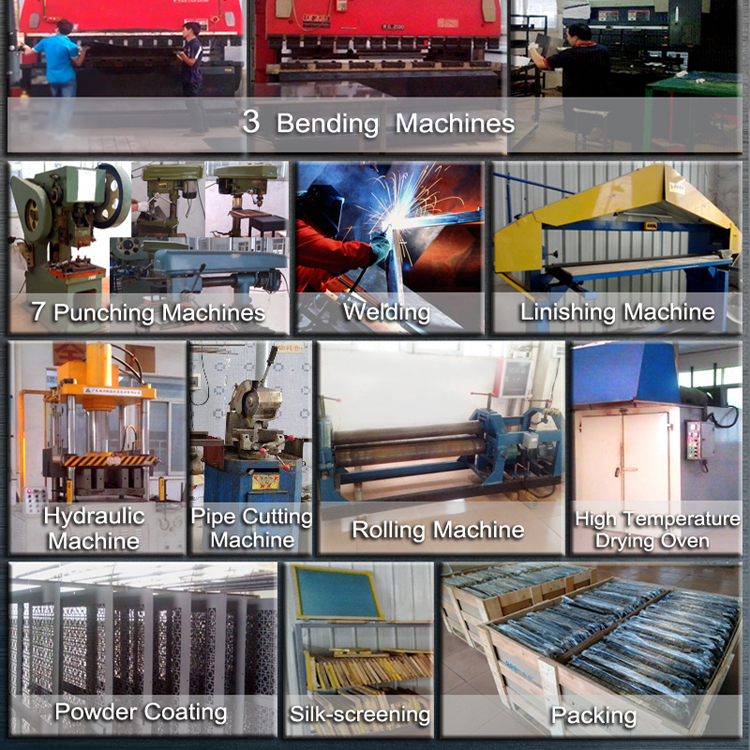

Major fabricated equipment | AMADA Laser cutting machine AMADA NCT punching machine 3 AMADA bending machines TIG/MIG welding machines Spot welding machines Stamping machines Oil hydraulic press Riveting machine Pipe cutting machine Rolling machine Linishing / Brushing machine Powder coating line High temperature drying oven |

Laser Cutting | 1. Usual materials use for electrical cabinet Stainless steel 304 / 316, cold/hot rolled steel, Galvanized steel(SGCC), SECC, aluminum alloy 5052 / 6061, etc. |

2. Applicable thickness for electrical cabinet Steel: less than 20mm Stainless steel: less than 12mm | |

3. Details: Equipment: 4000W AMADA FD-3015NT Laser Cutting Machine Place of Origin: Japan Cutting Dimension: 3000*1500mm Feature: High precision, less burr | |

CNC Punching | Equipment: AMADA NCT Punching Machine Place of Origin: Japan Cutting Dimension: 2000*1200mm Cutting thickness: Less than 3mm Feature: Lower cost |

CNC Bending | Equipment: AMADA Bending Machine Quantity: 3 Place of Origin: Japan Bending Dimension: 3000mm Bending thickness: Less than 6mm |

Small punching machines | Quantity: 8 Application: Riveting, countersink, clinching, drilling etc. |

Oil Hydraulic Pressing Machine | Making simple patterns on flat metal plates or stamping. |

Brushing | Satin polishing (linishing) for flat metal plates such as stainless steel and Aluminum. |

Pipe cutting | Cutting all kinds of pipe ( round, square), rod, angle steel,SHS etc in different angles and length. |

Rolling | Rolling metal sheet in different sizes & curves |

Welding | TIG welding, MIG welding, spot welding, fulll welding etc. |

Treatment | Powder-coating and silk screening is handled in house, painting, zinc-plating,nickel-plating, black or clear anodizing, plastic coating, laser engraving or etching is outsourced. |

More information for electrial cabinet service :

Item | Custom electrical cabinet assemblies manufacturing |

Product Category | sheet metal electrical cabinet fabrication |

Work flow | Laser cutting / NCT punching, bending, riveting, structural welding, polishing, powder coating, silk screening, assembling, packing&delivering |

Remarks | 1.Sample for electrical cabinet is always welcome. 2.Small order for electrical cabinet also acceptable 3.Design for electrical cabinet according to clients' ideas |

sheet metal electrical cabinet fabrication is only a small part of our manufacturing range,besides electrical cabinet fabrication ,we also spesilized in custom metal display racks fabrication,there are related custom sheet metal fabrication product photosas follows:

Custom metal display rack

The custom metal advertising rack was for displaying high quality granite plates in client’s showroomsand many stores or shops in Australia. As carrier of high quality goods, the metal display shelves are requested to be high-end as well, which can be shown from product details,

such as smooth corners, all round edges with nearly same radius, excellent Mannex black powder coated surface. Besides, it was important to keep all display brackets on the same level and parallel.

As it was Bo Jun’s first trial of offering sheet metal fabrication service in advertising display equipment industry, the success was important for Bo Jun’s development into new markets.

Power supply equipment sheet metal leakless enclosure

We are extremely well equipped to provide customized solutions to your sheet metal equipment enclosure needs. We have a team of 6 engineers who have at least 20 years of experience and knowledge combined to serve your enclosure requirement.

Sheet metal equipment enclosure

Metal enclosure refers to a wide range of custom sheet metal enclosure, such as ATM enclosure, jukebox

enclosure, vending machine enclosure,or any other customized equipment enclosure applied in all kinds of

industries. We are extremely well equipped to provide customized solutions to your sheet metal enclosure

needs.

Stainless steel fabrication

Customization is available in all types of materials including carbon steel, galvanized steel, 304 or 316 stainless steel. We have the ability to precision cut all holes and cutouts, custom paint and finishes as well as manufacturing custom sizes with the same high quality as standard enclosures and quick turn around times. We also do passivation for stainless steel parts in house.

Sheet metal chassis

We make custom fabricated sheet metal chassis and covers for electrical and electronic enclosures and components. Chassis can be plated, painted, powder coated and silkscreened. Aluminum, cold rolled steel and stainless steel sheet metal chassis can be fabricated from a variety of material thickness.

In Bo Jun, you will find us as your own professional customized sheet metal fabrication

supplier who offers world-class service and client-orientated solutions.

Bo Jun provides sheet metal fabrication service in all walks of life.

All in all, here are our service list for your reference:

We handle in a careful and economic way for ocean shipping, like paper box,pallet,or carton. Package size and

container loading quantity are calculated by engineers based on products size in order to work out a best solution.

Every piece is fixed by protective foam,plastic tape,batten etc. to protect products from shipping damage.

To conclude:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.

- Q:Do you make customized products based on our design drawings?

- A:Yes, we are a professional metal fabrication factory with an experienced engineering team making custom products according to clients’ drawings. We use Solidwork, AutoCad, ProEngineer softwares.

- Q: What is your MOQ?

- A: Usually we don’t set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

- Q: How much is your sample fee? Is it refundable?

- A: Usually sample fee is three times of batch unit price and it will be returned during mass production.

- Q: How long is your lead time?

- A: It depends on the quantity and difficulty of products. Usually our turnover time is 20-30 days.

- Q: Do you handle powder coating and silk screening yourself?

- A: Yes, we are a professional sheet metal fabrication factory providing full set of manufacturing service including laser cutting, NCT punching, bending, welding(TIG, CO2 arc welding), grinding, belt polishing, powder coating&paint coating, silk screen.

- Q: Could you help us with warehousing?

- A: Sure, we have plenty of space in factory and we are glad to make full use of it by warehousing products for clients even for one year.

China

China