High efficiency screw press sludge dewatering machine for waste water treatment

Screw Sludge Dewatering Machine Features:

1.Suitable for sludge dewatering of high/low consistency.

2.There is no need to worry about jam up. Reduce the cleaning water consumption.

3.The electrical cabinet, disposal tank and dehydrator are integrated, which reduces the covering area and brings convenience to installment.

4.The dehydrator is enclosed working, which reduces the bad smell and improves the working environment.

5.Automatically working for 24 hours, reducing the labor strength of workers.

6.The slow running speed of screw shaft reduces the power consumption and noise.

7. It is made with stainless, extending the service life.

8. It is convenient for daily maintenance.

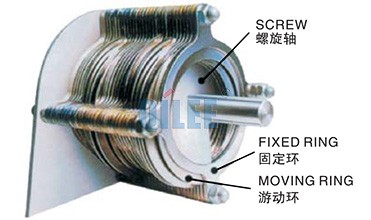

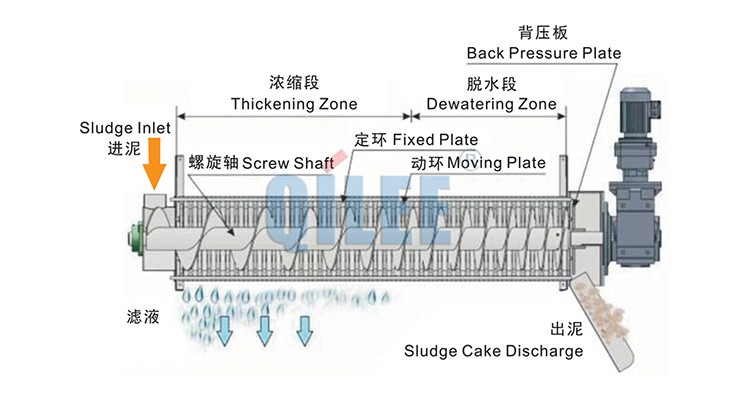

The main part of the dehydrator is a filter device that a screw runs through the stacked fixed rings and moving ring.

The small gaps between fixed rings and moving ring can filter the sludge, and the lumenbetween screw and rings is filled with polymer grains. The moving ring transfers the sludge to the end of the machine with pressure and extrudes sludge cakes.

The running of the screw drives the moving ring to clean the gaps and avoid jam.

•City mixed raw sewage

•Food & beverage industry

•Chemical industry

•Stone & mine sewage

•Leather & tannery sewage

•Paper & pulp sewage

•Elecro-plating sewage

•Pringting & dyeing sewage

•Power plant

•Petrochemical industry

1.The sludge in the sludge sump is carried to the measuring tank by sludge pump.And the sludge inlet volume can be controlled by adjusting the liquid level tube.

2.Sludge and flocculant will form alum floc in the disposal tank after agitator mixing, the ideal diameter of alum floc is about 5mm.

3.After gravity thickening in the thickening part, large amount of filtrate will discharge from the gaps between rings.

4.The thickened sludge is carried forward by the screw and dehydrated sufficiently under the pressure of the back pressure plate.

5.The dehydrated mud cake is discharged from the gaps between back pressure plates and screw body. The treating capacity of sludge and water content's rate of mud cake can be controlled by adjusting the running speed of screw and gaps between back pressure plates.

China

China