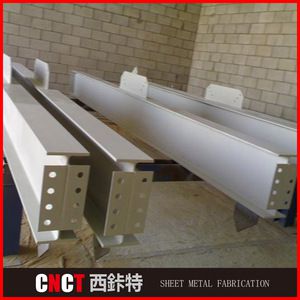

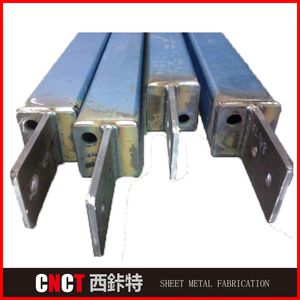

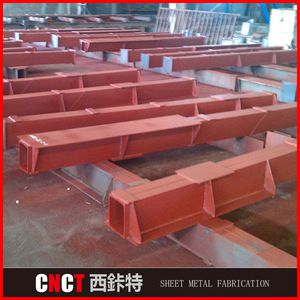

Made in China Q235 processing steel structure

Our Products

Features of steel structure fabrication:

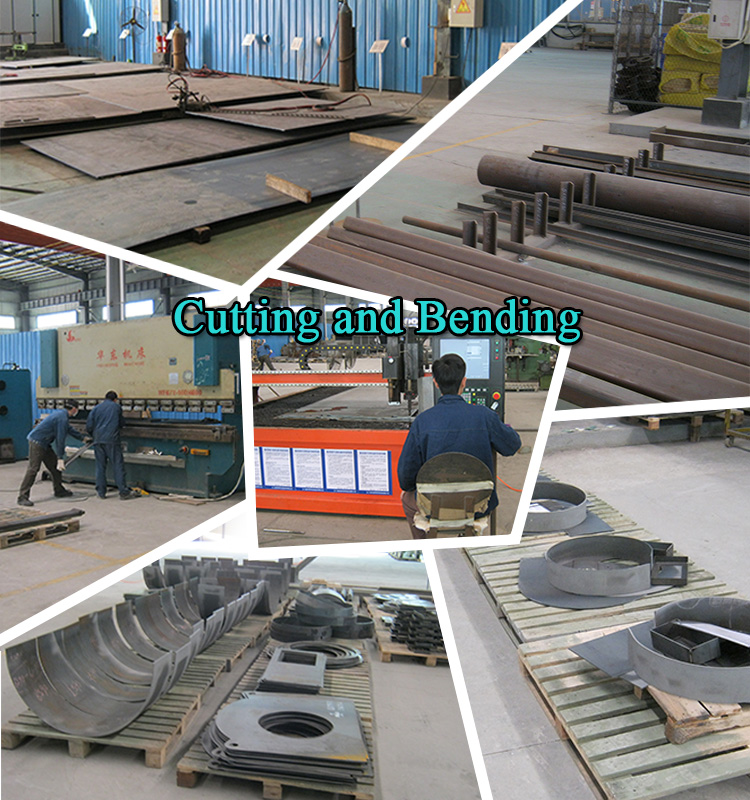

- Owing plasma cutting, high-power laser cutting and water jet cutting. available to provide multiple cutting service.

- Well-experienced engineer team and production team for steel structure fabrication, welder working with CWI certificate, according to WPS(welding procedure specification) and PQR(procedure qualification record).

- Professional non-destructive testing, fully equipped.

- Professional surface treatment: hot-dip galvanizing, sandblasting, paint spraying, powder coating, plating.

- More than 5 years steel structure fabrication experience.

- Full set of manufacturing process plan to ensure delivery on time.

Specification of steel structure fabrication:

| Material: | 3-30 mm structural steels( especial Q235B/A36); stainless steel; sheet metal; carbon steel; angle iron; tube; box iron; joist steel. |

| Welding technology: | Standard of Constructional steel: AWS D1.1 |

| Standard of pressure vessel: ASME | |

| Welding Method: | GMAW / GTAW / FCAW / SMAW |

| Welding code: | WPS PQR |

| Surface Treatment: | Sand blasting, paint spraying,Powder coating, Zinc plating, hot-dip, Silkscreen, polishing and so on |

| OEM experienced: | OEM Service based on drawings or samples from customers. |

Processing Flow

We offer a one stop shop for sheet metal fabrication services!

CNCT owned domestic advanced sheet metal processing production lines. Equipped with laser cutting, CNC shearing, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, silk screen printing, assembly and other large workshop, has all kinds of advanced testing equipment, perfect detection means.

- More than 10 years trading and manufacturing experience.

- Small order is available.

- Superior Favorable price Good service.

- Delivery on time.

- Hard work of our QC team employee guaranteed the stable quality.

- Well- experienced in providing production for Custom design and OEM order.

| Material available | Stainless steel 201/304/316, sheet metal ( SPCC, SECC), aluminum alloy etc. |

| Fabrication service | Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, machining, surface treatment, and other General Fabrication Service |

| Surface Treatment | Powder coating, Zinc plating, chrome plating, hot-dip, Silkscreen, polishing and so on. |

Main Process

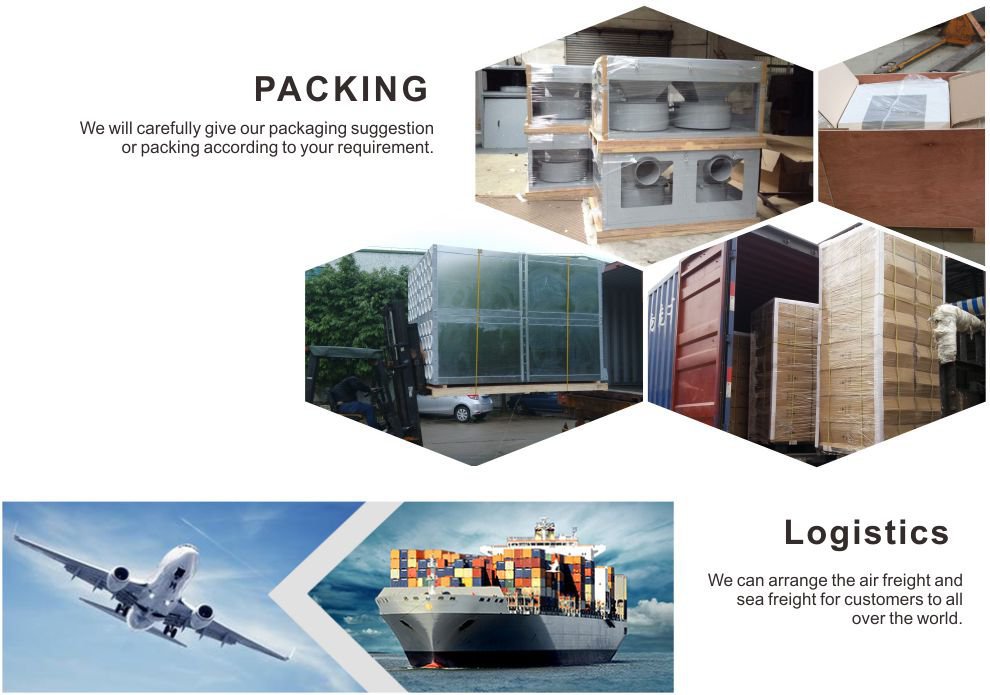

Packaging & Shipping

China

China