Waste water treatment evaporator, continuous crystallization evaporator

Concentrator/Evaporator

1 Wide use range

2.energy saving

3, Good appearance,

4, Auto control

1.Product Description

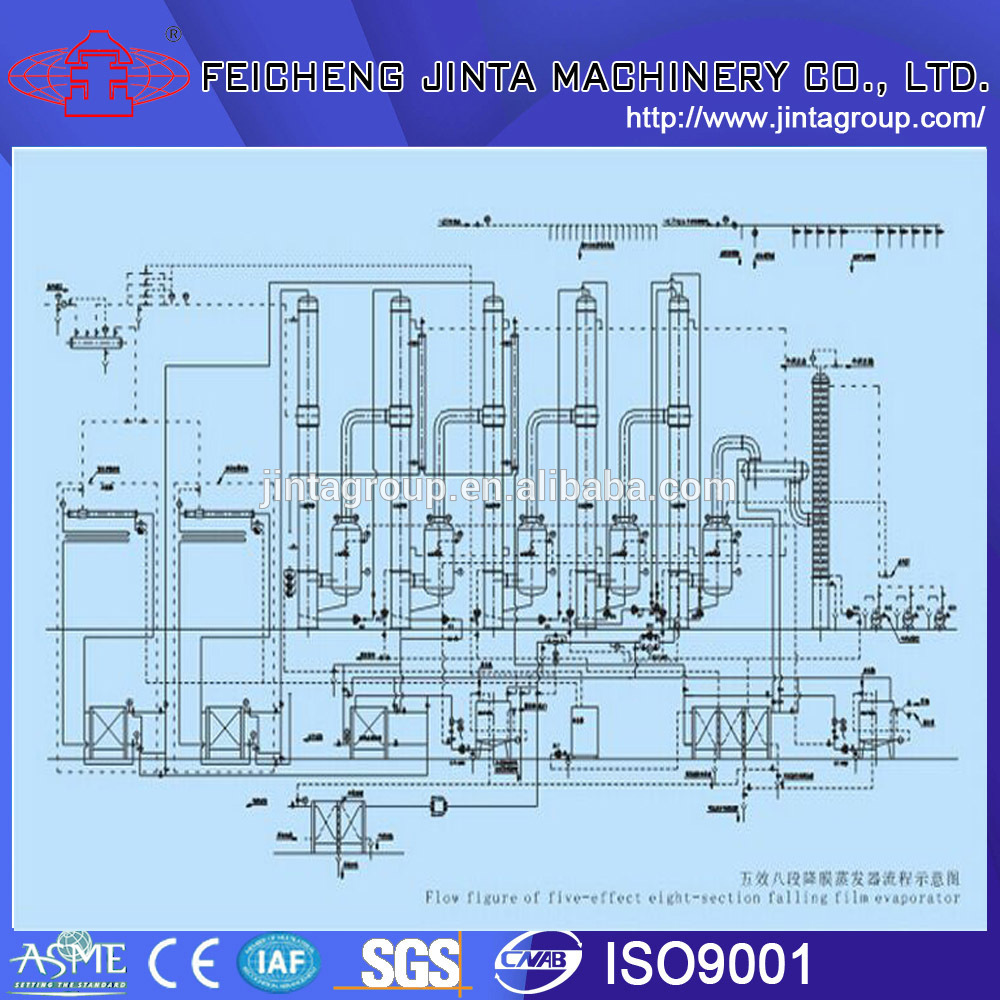

The evaporator series (three effect & multi effect falling film evaporator) allowed arranging special process flow according to different feature of material. It can also designed according to customer's special requirement.

Its outstanding advantage lies in the point that it can fulfill the continuous operation and low temperature evaporation. It saves energy and time with low loss and maximize remain the material's color, fragrance and favor. It can satisfy the continuous production requirements. This product is mainly used in the industries such as food, Chinese and Western pharmaceutical, biochemical pharmaceutical, further processing of agricultural and auxiliary products, health drinks, juice, fine chemical, light industry, PRO-environment etc.

2.Equipment structure

It consists of (first-effect, second-effect, third-effect)separators and evaporators and preheaters, condenser and vaccum pump, feeding pump, circulation pump, discharge pump, condensed water pump and system pipe fittings, etc. Equipped wit CIP spraying cleaning ball, vacuum gauge, thermometer, pressure gauge, and so on.

3.Equipment characteristics

1.The whole system with reasonable and beautiful design, stable operation, high efficiency, energy saving and low steam consumption.

2.Large concentration ratio, forced circulating type, which can make the materials of larger viscosity easily flow and evaporate and shortens the concentration time.

3.The special design can make modifications of effects easily to realize production of various products.

4.Low evaporation temperature, the heat quantity can be fully used, the heating of materials is warm, so it's applicable for concentration of heat sensitive materials.

5.After forced circulation, the evaporator is heated evenly in the pipe with high heat transfer co-efficent, in order to prevent the occurrence of "dry wall".

6.The materials and liquids are separated after coming into the separator, the effect of separating is greatly improved and it's flexible to operate.

7.The whole set equipment is quite compact, and occupies little area, and the layout is simple and fluent, all of which are the developing tendency of lare sized whole set evaporating equipments.

8. Continuous materials inlet and outlet, and the liquid level of mateials and needed concentration can be automatically controlled.

9.Evaporation capacity: Evaporation capacity: From 500Kg/h to 80T/h like 3000l/h-4000l/h-5000l/h-8000l/h-10000l/h-12000l/h-15000l/h-20000l/h-25000l/h-40000l/h etc.

4.Application

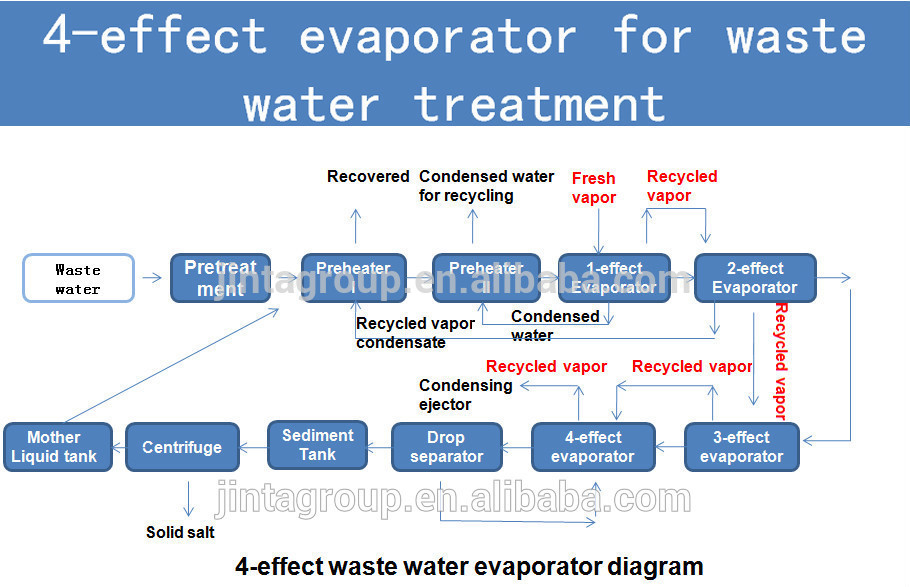

The falling film single-effect, double-effect, triple-effect and multi-effect evaporators are applicable for low temperature concentration of high concentration and high viscosity materials containing indissoluble solid things in food, medicine, chemical industry, biological project, environment protection project, and waste liquid recovery& treatement etc, industries.

The machine can widely used in the concentration of the glucose, starch sugar, xylose, citric acid, ammonium sulfate, oligose, maltose, sorbierite, milk, juice, vitamin C, maltodextrin and other aqueous solution. And also widely used in liquid waste disposal such as industry field of gourmet powder, alcohol and fishmeal.

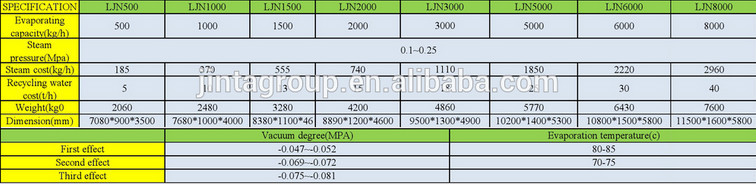

Technical parameters of falling film evaporator

Type | Single effect | Double effect | Three effect |

Evaporative capacity (kg/h) | 300-2000 | 1200-4000 | 3600-15000 |

Feeding material density % | According to material | ||

Discharge material density % | According to material | ||

Steam pressure | 0.5-0.8 | ||

Steam consumption / Evaporative capacity(with heat pressure pump) | 0.65 | 0.38 | 0.28 |

Evaporating temperature | 45-90 | ||

Sterilizing temperature | 90-110 | ||

Cooling water consumption / Evaporative capacity (inlet 20°C, outlet 40°C) | 28 | 11 | 8 |

Note: we can design products according customer's requirement. |

5.New Technology Description

Five-Column Three-Effect Distillation Process

Our company designs and manufactures latestFive-Column Three-Effect Distillation equipment.This new process is promoted on the basis of traditional five-column differential-pressure column and mainly used for super-fine alcohol production.

The key of this process is the heating methods,the steam heats one column directly and transfers theheat to other 4 columnsto achieve three-effect thermal coupling and energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing of circulating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table for Super-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | Steam Consumption | t/t | 3.0 | 2.3 |

2 | Colority | No. | 9.5 | 8 |

3 | Alcohol | %(v/v) | 95.5 | 96.5 |

4 | Sulfuric Acid Test | No. | 70 | 9 |

5 | Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | Methanol | mg/l | 18 | 3 |

7 | n-propyl alcohol | mg/l | 15 | 2 |

8 | Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | Acid(as acetic acid) | mg/l | 19 | 9 |

10 | Ester (as acetic ether) | mg/l | 22 | 16 |

11 | Nonvolatile matter | mg/l | 23 | 12 |

12 | Heavy metal(as Pb) | mg/l | 0.65 | 0.4 |

13 | Cyanide(as HCN) | mg/l | 3.7 | 2 |

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production of general-grade alcohol& fuel ethanol, and it was awarded Chinese national patent, it is the onlysuccessfulapplicationof double mash column & three-effect in the world,which produces general-grade alcohol.

This process is composed by mash column, rectification column and composite column. The composite column functions as mash column and rectification column.

The key of this process is the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | Electricity Consumption | kwh/t | 15 | 20 |

2 | Steam Consumption | t/t | 2.3 | 1.4 |

3 | Water Consumption | t/t | 7 | 5 |

4 | Colority | No. | 9.5 | 8 |

5 | Alcohol | %(v/v) | 95.5 | 95.5 |

6 | ulfuric Acid Test | No. | 70 | 55 |

7 | Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | Methanol | mg/l | 100 | 55 |

9 | n-propyl alcohol | mg/l | 75 | 35 |

10 | Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | Acid(as acetic acid) | mg/l | 19 | 18 |

12 | Ester (as acetic ether) | mg/l | 22 | 20 |

13 | Nonvolatile matter | mg/l | 23 | 21 |

14 | Heavy metal(as Pb) | mg/l | 0.65 | 0.5 |

15 | Cyanide(as HCN) | mg/l | 3.7 | 3 |

6.Our Services

Production Capability

1).Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China.

2).Our company can produce 6 full sets of equipment (including crushing section, liquefying and saccharification section, fermentation section, distillation section and DDGS section) in a month.

3).Among 16 production workshops, 3 workshops are for mechanic manufacture, 5 workshops are for manufacturing process, 8 workshops are for assembling & welding.

4).We own advanced machining equipment and product testing equipment.

Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2). Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3). Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification.

7. International Exchange and Cooperation

JINTA is the largest designer and manufacturer of alcohol, fuel ethanol and DDGS equipment machinery in China. Our market of alcohol equipment in China keeps over 60% in the past 3 years and our products has been exported to more than 30 countries such as Australia, Argentina, Brazil, Russia and etc. We can develop different programs according to customers' raw materials and annual production and have advanced process technology, especially in energy consumption.

8. Packaging & Shipping

9 .Contact us

China

China