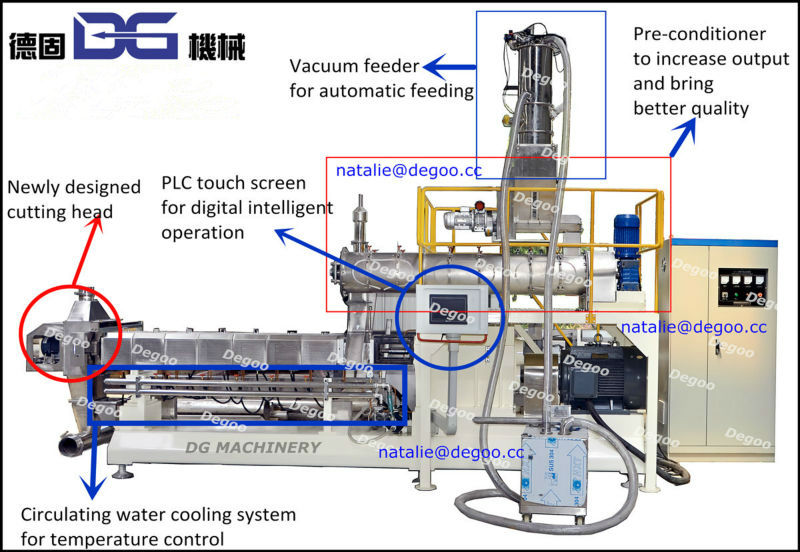

High Capacity Food Grade Modified Corn Starch Making Machine uses cheap natural starch, like corn starch, cassava starch, tapioca starch etc as main materials, through extruding treatment process, to produce multi-functional and high-valuable modified starch, Pre-gelatinization Starch or Denatured Starch. Its Double Screw Extruder is special designed, consists of 6 systems: feeding system, extruding system, cutting system, heating system, conveying system and cooling system, its barrels and screws structure can easily realize the function of changing the properties of the starch. Modified Starch can be used in many fields like Textile, Food, paper making, building material, casting, oil drilling and so on.

1. Raw Materials: natural starch, like corn starch, cassava starch, tapioca starch etc

2. Products: Modified Starch.

3. Capacity: 120-150 KG/H,200-250 KG/H,400-500 KG/H

4. Flow Chart: Mixing —Extrusion —Baking —Grinding

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

Model | Installed Power | Power Consumption | Output | Size(L×W× H) |

DG65 | 63kw | 45kw | 150kg/h | 20000x1200x2200mm |

DG75 | 145kw | 87kw | 200-250kg/h | 21000x1500x2200mm |

DG85 | 153kw | 92kw | 400-500kg/h | 31000x3500x4300mm |

Why You Must Choose Us

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

2. Double Axis Differential Conditioner, Available for Steam, Pre-cooking and High Efficient.

3. Linear Slide Face Cutting System, Strong Power, Variable Frequency Speed and Large Output,

4. Unique Designed Square Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

5. Modular Circular Groove Screws, available for Different Extrusion Rate Applications.

6. Steam Heating System, ensure the Most Efficient, Continuous and Stable Heating Effects.

7. World-famous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect.

8. Main Motor from SIEMENS(CHINA), 90KW, ensure its Powerful Extrusion and Excellent Performance.

Products

We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

Strong Fumigation-Free Cases or 20' GP or 40' HQ

Our Prestigious Reputation Got form the World

Our machines are exported to more than 90countries and areas and got high praise of customers. Some of them have become our agents in their area. We hope to hold long friendly business relationship with more clients all over the world in the future.

Who We Are

We, Jinan DG Machinery Co., Ltd. is located in the famous industry city-Jinan city, capital of Shandong Province.

We are professional manufacturer of food extruder and mainly deal with the manufacture, research and development of the inflating food machine. According to the clients’ different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food and so on. Our technical assistance will help clients produce high quality products all the time.

As a leading manufacturer of inflating food machinery, we are selling and marketing the machines to many countries in the world. We keep improving our machines and upgrading techniques to satisfy the requirements of all the clients. Depending on our rich experience and professional experts on the extruded food industry, we could offer the most suitable and complete program to assure that your investment will get biggest profit.

We are Reliable and Certified

Since the establishment of our company, we have always manufacturing our machines according to the authorized standards, by now ,we have got several certificates including CE and we are 2 Years Alibaba Golden Supplier.

Our Most Popular Snacks Food Production Line

No. | Production Line |

1 | |

2 | |

3 | |

4 | Extruded Doritos / Tortilla Corn Chips Snacks Food Production Line |

5 | |

6 | |

7 | |

8 | |

9 | |

10 | |

11 | |

12 | |

13 | |

14 |

Contact Details:

China

China