CASSAVA POTATO STARCH PROCESSING MACHINE

The small type starch production line consist of the washing and peeling machine,feeding device,

grinding and filtering machine and starch purifying machine . The capacity is 0.5-5t/h ,which is

suitable for small farm , home using and small type vermicelli processing factory .

Raw materials:all kinds of root tubers, like cassava, kudzu root, potato, rato, lotus root, arrowroot, sweet potato, etc.

process:washing and peeling--crushing and extracting--second extracting--dewatering

1)washing and peeling

For 1t/h,2t/h,only one screw washing machine, for 3t/h,5t/h,two stage washer as follows, ensure final product could satisfy further process.There is many raised parts in the screw shaft, so the raw materails' skin and dirth things are removed when they are transported up.

2)crushing and starch extracting:

feeding port is compsed of roller with shape rack,when feeding, raw materails is crushed into very small pieces to drop to below chamber which is with inside brush and outer screen.The screen hole diameter is very fine, only starch with water could though it out from the screen,big scum come out from the end of the machine.

3)second starch extracting machine:

The instructure is same as above main machine, just inside screen hole is more fine, so you could better quality starch from this.

Above three step is for basic process, if you want to best quality starch and dewater more easily.Pls get another three machinery: fine filter, dewatering machine, drying machine.Finally get dry starch with moisture about 10%.

Item | Model | Power | Dealing capacity |

Potato/Cassava/Sweet potato starch Grinding machine | 1 | 3kw | 0.5t/h |

Potato/Cassava/Sweet potato starch Grinding machine | 2 | 5.5kw | 1t/h |

Potato/Cassava/Sweet potato starch Grinding machine | 3 | 7.5kw | 2t/h |

Potato/Cassava/Sweet potato starch Grinding machine | 4 | 10kw | 3t/h |

Potato/Cassava/Sweet potato starch Grinding machine | 5 | 20kw | 5t/h |

Machine detailed structure:

Machine in stock:

Machine in stock:

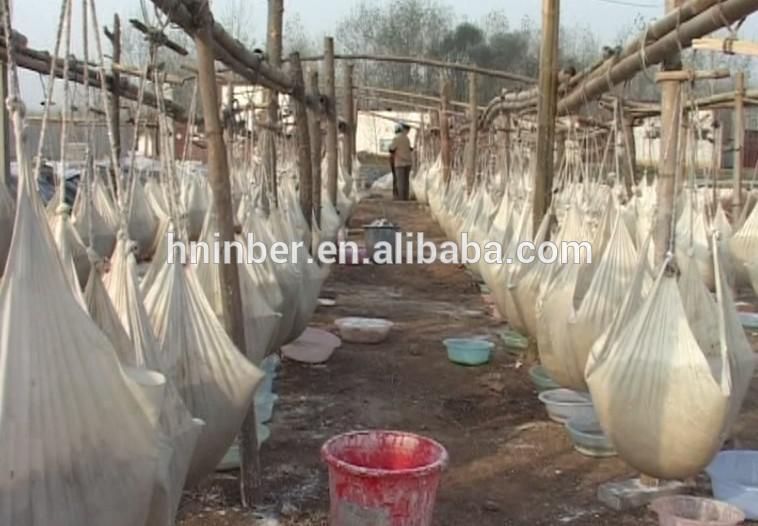

If only choose machinery from above three basic step, you will get final starch with water.

So pls dig some small tank to store that, letting them dry in the sun. After drying for about 1-2 days to moisture is about 20%,get them into small bags drying further till get your satisfyed one.

Any interest,pls confirm following details first:

1) your raw materials?

2)your input capacity?

3)how you want to dry the starch?

Then i could recommend you suitable machinery more efficiency.

China

China