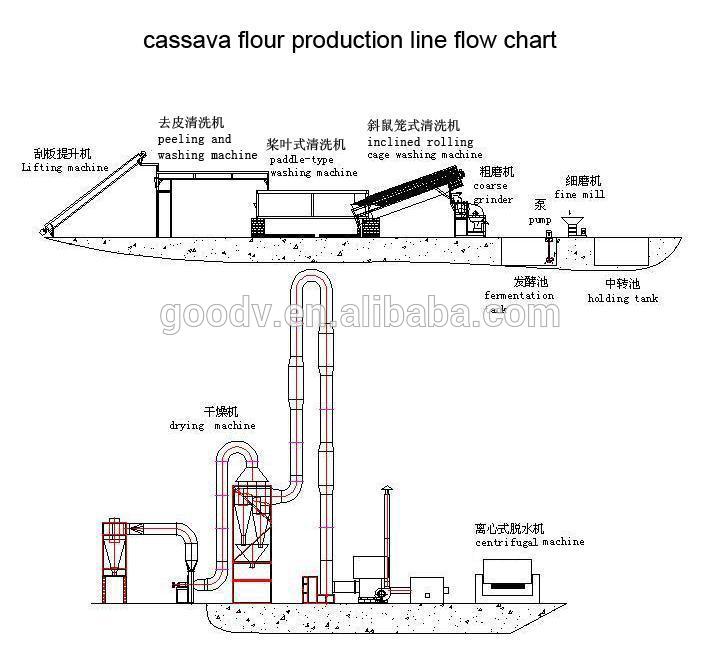

hydraulic press diagram in cassava starch flour processing plant

Pictures of cassava processing plant:

> Washing & Peeling Section of cassava flour processing plant:

To cassava, the material is sent to cage washer through scrape board to get the result of decontamination, cleaning and peeling. Then through a paddle-washing slot, material is sent to crash section.

We adopt the rasper to crash materials. Compared with traditional crasher, it has the large capacity, high flour dissociation degree features, which are essential to get high flour recovery.

> Milling & grinding section of cassava flour processing plant:

Grinding clean cassava root into cassava slurry to make it easy dewatering and drying.

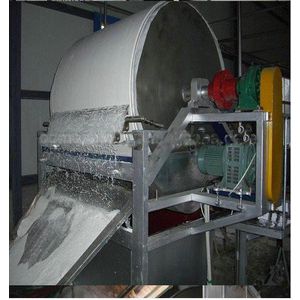

> De-watering section of cassava flour processing plant:

Sending the fine slurry to dewatering machine to remove the moisture inside the slurry, and then

send it to the air dryer.

Compared with other starch, it is more suitable for cassava flour to dewater by vacuum filter.

Moisture content of dewatered starch is 38~40%. Wet flour is sent to drying system through belt

conveyer.

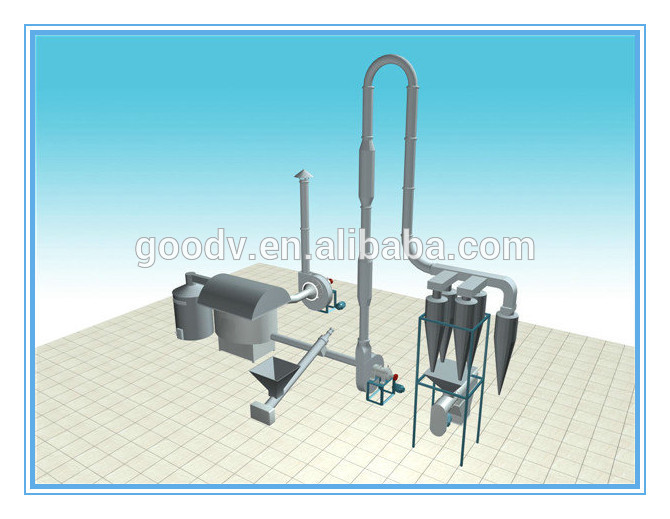

> Drying section of cassava flour processing plant:

Drying the de-watered cassava starch in the air dryer to get dry product.

Cassava flour reaches sieving system. High efficiency cooling starch sifter is used to cool

starch and get the best starch viscosity.

Leading the industry,Creating a world brand-the directly supplier:China Leading Manufacturer of Cassava ,Potato Starch& Grains Flour Milling Machinery(Machinery of Tapioca flour,Potato Starch,Cassava flour,Gari making and Grain flour milling)

Goodway Machinery Co. Ltd. specializes in research ,design and developing of starch and flour engineering including potatoes (sweet potato, potato, cassava, and Canna edulis Ker,Manioc ), and kudzu root ,wheat etc., manufacturing of complete equipment for starch processing and flour processing.

We lead the starch and flour industry since year1991 , up to now under the HeNan Agricultural

University and local governments support ,mainly offer the service of design ,manufacturing ,turn-key project and the solutions for cassava starch and grains flour milling industry ,machines involve in Cassava processing machine and flour milling machine such as Cassava Starch Washer and Cleaning Machine ,Cassava peeling machine ,Potato Peeling machine ,Cassava Starch Crusher

(national patent enjoyed) , Cassava Grater ,Rasping Machine ,Cassava Starch Filter ,

Cassava Starch Vacuum Drier ,Cassava Starch Hydro cyclones, Hydraulic Press ,Gari Making machine (Gari Frying Machine,Gari Fryer) , Cassava Starch Drying System,Grains Cleaning Machine ,Sifting Machine ,Flour Milling Machine etc.and others food processing machinery.at present ,Our products have entered African,East Europe, Middle East, South-east Asia ,and Russia etc.,markets.

Main Markets:

Africa:Nigeria, Gabon, Angola, Congo, Camaeroon, Ghana and so on

South Asia

Central America

Eastern Asia

Mid East

Oceania

Southeast Asia

Eastern Europe

South America

North America

Total Annual Sales Volume:US$5 Million - US$10 Million

Export Percentage:61% - 70%

After-sale Service / What you can get :

1. Process know-how and the process progress,

our staff will send you the process pictures and videos to you.

2. Pre-investment studies.

3. Feasibility / project reports.

4. Detailed engineering.

5. Turn key projects.

6. Equity capital participation.

7. Raw material testing .

8. After sales services .

China

China