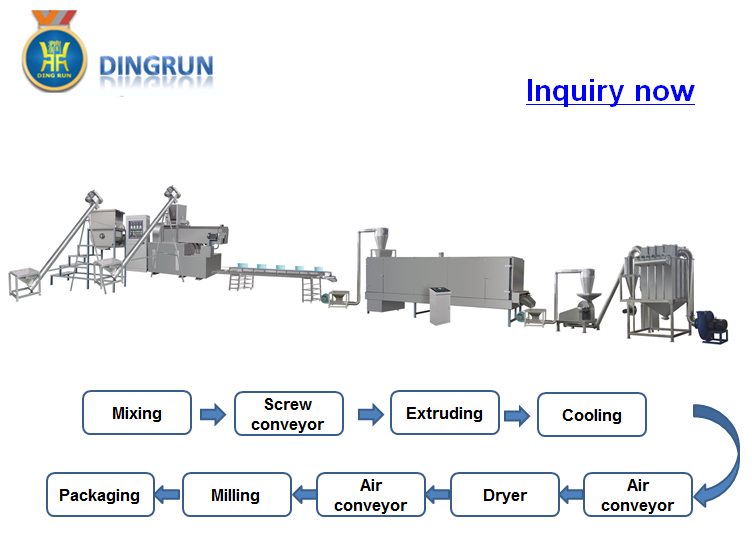

Pregelatinized cassava starch extruder production line

Description of Pregelatinized cassava starch extruder production line

Pre-gelatinized starch is an effective and economical fluid loss agent in water based drilling fluids, which is a starch derivative. It is not bacterial degradation at 120℃, environmentally acceptable and non-toxic.

Modified Starch can produce a thin, slick, tough filter cake and promote faster penetration rates with friction reducer. It can be used in all kinds of drilling fluid system. Pre-gelatinized starch is also sometimes "pregelatinized" to make them easier to dissolve during product manufacture. Modified starch is widely used in oil drilling, textile, paper and food industries.

Raw material of Pregelatinized cassava starch extruder production line

Natural starch, like corn starch, cassava starch, potato starch etc

The parameter of Pregelatinized cassava starch extruder production line

| Model | Installed power | Power consumption | Capacity | Dimension |

| DSE65 | 55kw | 40kw | 100-150kg/h | 19000*1300*2200mm |

| DSE70 | 70kw | 50kw | 200-250kg/h | 21000*1300*2200mm |

| DSE95 | 120kw | 95kw | 600-800kg/h | 30000*1500*2600mm |

Samples show of Pregelatinized cassava starch extruder production line

Jinan Dingrun Machinery Co,.Ltd is a professional extrusion machinery manufacturer.

With our many years' research and study, extrusion techniques have been widely used in many fields.

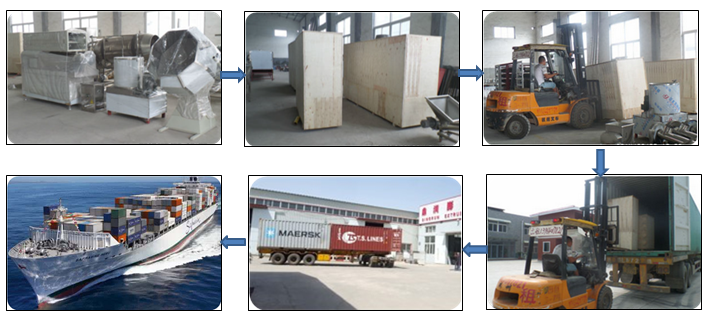

Packing and delivery for Pregelatinized cassava starch extruder production line

• Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

The customers visit show for Pregelatinized cassava starch extruder production line

As a professional extruder machine manufacturer, Jinan Dingrun Machinery Co,.Ltd has exported the food machines to more than 60 countries and regions, such as South Africa, India, Malaysia, Indonesia, Brazil and so on. Some of customers become our agents in their area. We hope to have long friendly business relationship with more customers from all over the world in the future.

Our professional service for Pregelatinized cassava starch extruder production line

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free long distance shipping management from seller's factory to named place by buyer;

5. Free maintenance and operating training personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warrantee and life-time maintenance service;

As a professional extruder machine manufacturer, we are responsible for the nature damage of the machinery in one year except for man-made damage. All spare parts and wearing parts are attached with the machinery for free; and these parts should be enough for one year use.

China

China