flour maI. Company introduction:

We, Hebei Jing Gang Machinery Co., Ltd is a professional enterprise which is specialized in manufacturing wheat, corn(maize) flour milling machines.

Our machines have high effcient and low energy consumption, which is designed by our professional engineers.

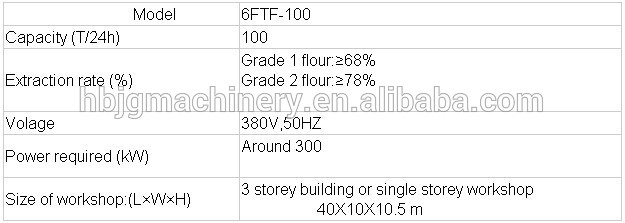

II. Main terms of the flour mill machines:

1. Voltage: 380V, Frequency: 50HZ. (Or as required) below an elevation of 1000m.

2. Time of Shipment: 30-90 days since receipt of 30% deposit.

3. Payment terms: T/T, 30% deposit, 70%balance before shipment or L/C.

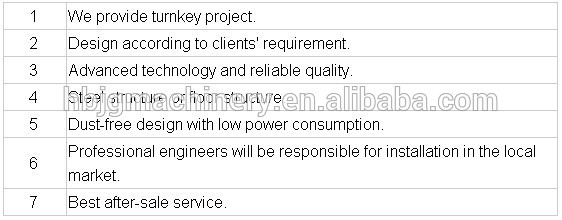

4. Installation terms: we provide a turnkey project of our machinery, including special design, installation, commissioning and training workers. We will send technicians to take charge the installation, test running, and training local operators.

5. Warranty: one year on part from date of invoice.

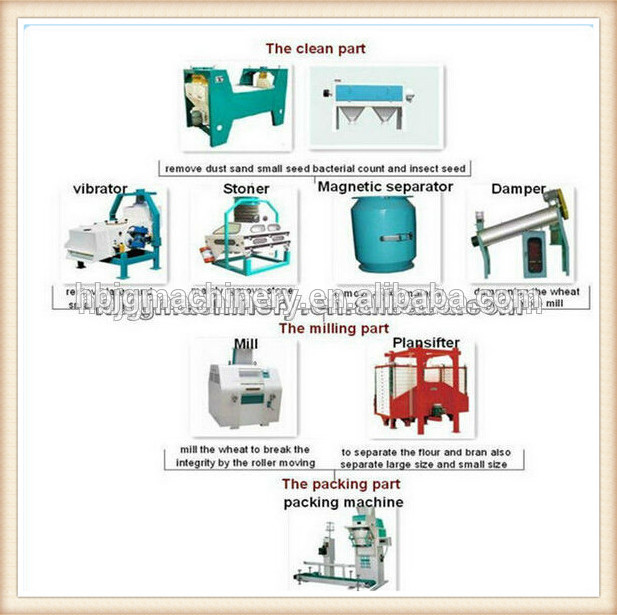

III. The process line of flour mill:

1. Cleaning part

to clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening. This section is to prepare for milling part and to protect the machinery as well.

2. Milling part

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving

(2) Sifter: to separate the flour, bran and other by-product, also separate large size and small size to ensure flour quality.

3. Packing part

The third step, the packing machine can be manual or automatic weighting and packing.

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working.

IV. The complete set of flour mill:

Small scale wheat flour mill machine:

10-30ton/24hours wheat flour mill machine:

50-100Ton/24hours wheat flour mill machine:

Large scale flour mill machine:

Maize flour mill:

V. The factory producing line:

VI. Packing&Shipping:

The machines are packed by plastic film inside and wooden cases outside or as customers' wish.

VII. Our service & advantages:

VII. Our clients&markets:

Please do not hesitate to contact us for further details:

Hebei Jing Gang Machinery Co., Ltd.

Add: 4-1-601, Jiaxingyuan, Wenyuan St., Xinhua District,

Shijiazhuang, Hebei

Tel:0086-311-8586 2830

Cel:0086 13171802817

Fax:0086-311-8586 2835

WhatsApp: 0086-13171802817

Website: www.hbjgmachinery.com

China

China