Maize milling production line

corn milling plant

Function of the maize milling equipment, maize milling

1. Corn milling machine, corn mill machine, corn flour mill machine, corn flour milling machine, maize corn flour milling machine, corn grinding mill.

2. Cleaning, peeling, crushing, polishing and sieve classifying into flour, grits as per customer's different requirements.

Main features of the maize milling equipment, maize milling

1. Dry milling technology save labor work

2. Fully automatic with high performance

3. Easy operation and mantainence and energy saving

4. High output rate of final products

5. Installation, staff training service

6. Reasonable price

About us

We are a professional manufacturer of flour machinery. Design various types of maize flour milling machine and wheat flour milling machine. The core devices are all designed and invented by our company for the specific device, to make sure the product has high quality

We provide a turnkey project of our machienry, including special design, installation, commissioning and training workers. We offer a turnkey project 10T~1000T/24H.

Our Service

We provide a turnkey project of our machinery, including special design, installation, commissioning ,training workers. All of our equipment contain one year free spare parts,and Quality guarantee period of one year.At the same time our company will carry on the lifelong service to our product.

1. cleaning part

to clean out the middle and small impurity from maize. e.g., dust, stone, magnetic material, maize was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening.this section is make the maize to prepare for millling part and to protect the machinery as well.

2. milling part

Include different number of mill and sifter to mill the maize and separate the flour and bran

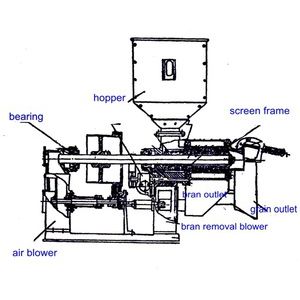

(1) Mill: mill the maize to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to enssure flour quality.

3. Packing part.

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working

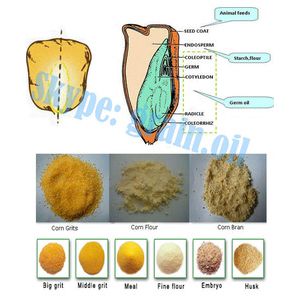

1. This series of corn product line build up with: corn process equipments (e.g.: corn huller, corn polisher, germ extractor, new super fine corn grits machine etc.) and foodstuff process general equipment (e.g.: hoist, density corn destoner, plansifter, miller, flour cleaner). The quality of finished products: corn flour and fine feed up to 80-120 mesh.

2.The maize flour milling processing plant use dry milling technologies. Compare with wet milling and semidry milling, the products do not need to be bake out, which reduce the cost for desiccation, e.g.: area, equipment, fuel, human resources etc., consequently reduce a major invest for our clients;

3.The roller mill is the main equipment for milling section in flour mills. It mainly depends on a pair of differential transmission and relative rotation rolls to break , meanwhile, scrapes endosperm from maize bran, then endosperm grinding into flour. The material can be extruded, sheared and broken during the equipment working and so as to achieve a certain grinding effect, each roller mill has two independent drive, feeding, and grinding systems and play their functions in the flour passages.

4. The line has simple structure, high adjustability for the field area and the workshop, no special requirements. Effectively cut down the fixed investment; Simple installation, fast construct progress, short construction period, allow our clients to meet the benefits in the shortest possible time

5.The complete system line has: advanced technology, excellent equipment, strong specific usage, logical constructer display, low energy cost, high yield rate, and high quality product etc. significance points.

This maize flour milling processing plant is suitable for food companies, starch sugar companies, and breweries companies.

China

China