Corn maize Grits Flour milling machine

1 Steel Structure or building

2 novel designs,

3 low price

4 free spare part

High quality Corn maize Grits Flour milling machine

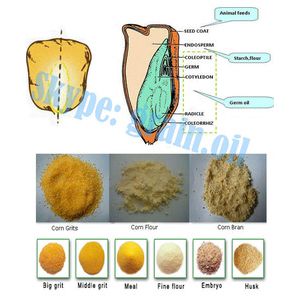

Adopting the dry process technique: dry peeling and degerming technology, FTA complete set maize milling machine can produce low fat corn grits, corn meal, corn flour with different sizes at the same time. Corn grits size can be customized as per customers’ need in order to meet various of needs such as brewery, snack food, glucose, sugarhouse. Thanks for the dry peeling and degerming technology, husks and germs collected at the end don’t need to be dried before used for animal feed.

Final products | output yield | fat content | Size |

Corn grits | 45-55% | <0.8% | Mesh 8-40 |

Corn flour | 20-30% | <1.5% | Mesh 50-80 |

Animal feed | 25% | High | Normal |

Corn maize Grits Flour milling machine Final products parameter

1, Sand content: <0.02%

2, Metal content: <0.003g/kg

3, Water content: 13.5-14.5%

4, Color and smell: regular

PROCESS of CORN DRY MILLING

Raw material corn Maize- bucket elevator-separator-magnetic box-low pressure air blower-destoner- bucket elevator-air aspirator –emery roller dehuller-tank- emery roller dehuller-iron roller polisher- bucket elevator-grading sieve-germ separation table-hammer mill-grits polisher- bucket elevator-flour sifter-husk separator-plan sifter- low pressure air blower- air aspirator- Grits packaging.

The whole fully automatic production line is consists of

Cleaning part---Peeling/dehuller/degerming part---Milling and sifting part

Ⅰ. The cleaning section

We do this part just want to ensure:

a. the quality of corn flour.

b. the life of machines.

This section is separate the impurity like smaller stone, sand, grass seed, swarf from the raw corn .

The main machine:

Raw material corn Maize- bucket elevator-separator/ vibrating screen-magnetic box-low pressure air blower-Destoner

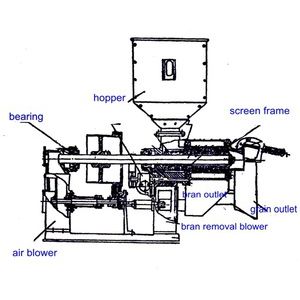

Ⅱ. The peeling/dehuller/degerming section

This is the most important part of the whole plant. Because the working condition of this part will determine the quality of final grits and flour.

The main machine:

- bucket elevator-air aspirator –emery roller dehuller-tank- emery roller dehuller-iron roller polisher- bucket elevator-grading sieve-germ separation table

Ⅲ. The crushing milling and sifting section

The dehulled corn will go through hammer mill and single passage roller mill/ double roller mill for further processing. We will get grits with different sizes and flour at the certain outlets.

The main machine:

-hammer mill-grits polisher- bucket elevator-flour sifter-husk separator-plan sifter- low pressure air blower- air aspirator- Grits packaging.

Corn maize Grits Flour milling machine

Our Advantages:

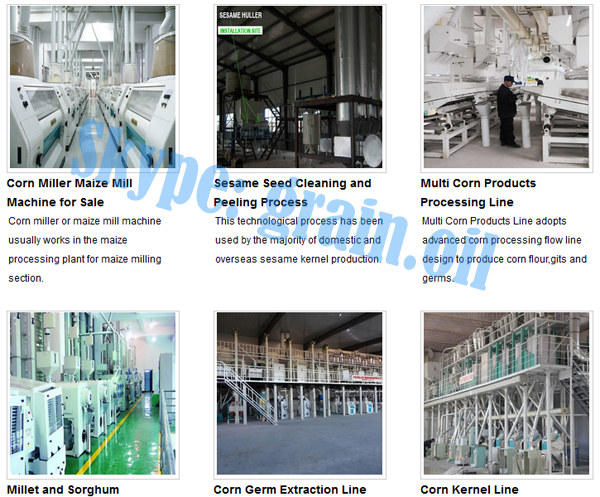

- 10T-500T/D complete Maize/Corn/Wheat/Rice Milling machinery.

- :Invite Dry/Semi-dry Methods to process Corn/Maize in the whole production line.

- research and development group:Cooperating with “National Engineering Laboratory for Wheat &Corn Further Processing” from Henan University of Technology.

- and low power consumption.

- and advanced technology support.

We are ISO9001, BV Certified Factory in China, Henan province. As a Professional Manufacturer of Grain Processing Machinery, we are specialized in project design on Grain Milling Plants of Wheat/ Rice/Corn/Maize Flour/Grits and other Cereals.

Besides the complete sets Grain Milling plants, we also supplyStandalones below:

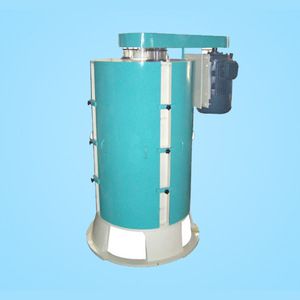

l Cleaning machines: Vibrating sieve, Separator/Classifier, De-stoner, de-duster, filter

l Peeling/Degerming machines: Dehuller/Polishing machine, Degerminator, Germ- Extractor, Grinding machine,Pulverizer, Crusher, etc

l Milling machines: Hammer Mill, Roller mill, Plan -sifter/Sieve/Flour sifting machine.

l Packing machines; Pellet machines; Oil Press/Oil Refining plants, etc.

China

China