1. The clean part:

Includes beating, screening, destoner, magnetic separator and dampening. Different capacity machine line has different number of beat, screen and stoner.

To ensure the flour Quality and the working life of the mill by removing the impurities in the wheat before go to mill,

Beat: Through the beat function of the wheat scourer, brusher to remove dust sand small seed, bacterial count and insect seed.

Screening: To remove large and small impurities in the wheat seed by make the wheat go through vibrating sieve and aspiration sieve.

Destoner: Mainly remove stone in the wheat to protect them milled into the flour and also protect the roller on the milling process.

Magnetic separator: Remove metal material in the wheat to keep the roller safe and also avoid flour exploration accident of spark caused by the impact of the metal impurities and the machine.

Dampening: Dampening the wheat bran before mill to ensure the bran's integrity during the milling processing, avoid the bran going into the flour to keep flour quality.

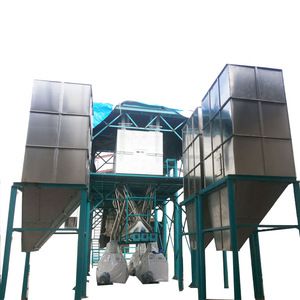

2. The flour milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: Mill the wheat to break the integrity by the roller moving

(2) Sifter: To separate the flour and bran, also separate large size and small size to enssure flour quality.

3. Packing part.

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. Adjustment and Operation of The Equipment

A. Maize cleaning part, peeling part and embryo separating part

Bucket Elevator III → Beating peeler → Bucket elevator II → Damper → No.5 Low pressure blower →Combined cleaning machine → Bucket Elevator I

B. Flour milling part

No.5 Blower → Motor for flour discharger → No.5.5 Wide blower → Motor for air seal → No.2 Plansifter → No.1 Plansifter → 4th Break → 3rd Break → 2nd Break → 1st Break

50T/24H wheat flour milling complete plant was installed in Zimbabwe in 2008. |

50T/24Hwheat flour milling complete plant was installed in Ghana in 2008 |

80T/24H wheat flour milling complete plant was installed in Ethiopia in 2009 |

100T/24H maize milling complete plant was installed in South Africa in 2010. |

100T/24H wheat flour milling complete plant was installed in Zimbabwe in 2010 |

60T/24H wheat flour milling complete plant was installed in Brazil in 2010 |

50T/24H wheat flour milling complete plant was installed in Argentina in 2010 |

20T/24H maize flour milling complete plant was installed in Angola in 2011 |

50T/24H maize flour milling complete plant was installed in Venezuela in 2011 |

100T/24H maize flour milling complete plant was installed in Venezuela in 2011 |

50T/24H maize flour milling complete plant was installed in Uganda in 2011 with steel warehouse and silos. |

30T/24H maize flour milling complete plant was installed in Uganda in 2011 with steel warehouse. |

15T/24H maize flour milling complete plant was installed in Kenya in 2011 |

China

China