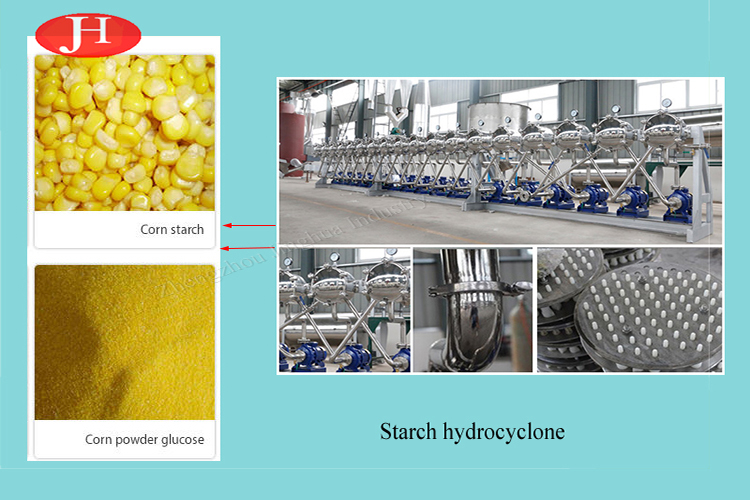

Hydrocyclone machine for corn starch processing plant

ZZJH Starch hydro cyclone is used to each kind of starch and modified starch emulsion degreasing, fine slag separation, protein separation, washing and enrichment, etc. Continuous concentration and separation of food industry suspension, clarification, etc.

With compact structure, high precision, as well as good sealing effect, is widely used in potatoes, cassava, sweet potatoes, corn, wheat, valley (m) starch, and modified starch.

Applications:

1.Starch recovery in potato starch line

2.Starch concentration in corn and wheat starch lines

3.A-starch and B-starch separation in wheat starch line

4.As splitter in wheat starch line to maximize A-starch recovery

Product show

Model | XL362 | XL438 | XL516 | XLS426 |

|

Plate quantity | 1 | 1 | 1 | 2 | Group capacity:3-12t/h |

Cylinder diameter(mm) | 362 | 438 | 516 | 426 | |

Cylinder norm(mm) | 10,15 | 10,15 | 10,15 | 10,15 | |

Feed Pressure(MPa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

Inlet Size(mm) | 76 | 89 | 89 | 2*89 | |

Underflow Size(mm) | 48 | 48 | 57 | 76 | |

Top flow Size(mm) | 57 | 57 | 76 | 2-57 |

Zhengzhou Jinghua Industry Co.,Ltd. is a specialized starch engineering technology company that is engaged in a variety of starch engineering design , equipment manufacture ,engineering installation and commissioning , technical staff training and so on .

Depending on the unique advantage and strong strength of Henan University of Technology, ZZJH produces machine making all kinds of starch . Such as potato starch making machine , sweet potato starch machine , cassava starch machine , garri machine , corn starch machine .

Packing : wooden cases/ customized

Delivery :25days after receiving pre-payment (on time according to contract strictly )

Q1: Is your company a factory or trading company?

A: Our company is a factory in Henan Province ,with export license

and we have done export business over 20 years professionally.

Q2.What is your main business?

A: ZZJH is devoted to starch processing machine. The machine of starch processing line , such as : cassava starch line , cassava flour line , potato starch line , sweet potato line , wheat starch ,sago line and garri line

Q3:Where is your factory located? How can I visit there?

A: Our add: Zhengyun Road and Guanggu Road intersection , Guangwu Town , Zhengzhou City , Henan Province , China.

Warmly welcome to visit us!

Q4: Are your products can be assured ?

A: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

Pre-sale service

1. Introducing detail features and application of the products to customer.

2. Selecting economical and practical machines for customer.

3. Providing operation data of the related machine.

4. Providing means of trial performance for customer.

5. Flow chart and factory designing layout .

Sale service

1. Recommending engineering conditions required for installation of the machine.

2. Communicating the manufacturing progress of machines with customer in time.

3. Project planning and design services;

After-sale service

1. Training of equipment maintenance and operating personally.

2.Installation and commissioning of equipment until everything is functional.

3. One year warranty and Providing long-term maintenance service and spare parts.

4. Giving technical support to customer for developing new product.

5. Engineers available to service machinery overseas.

6. Provide English Version of Installation/Operation/Service/Maintenance Manual.

Now, please click the following contact to send us email !

↓↓↓

China

China