high quality corn degerminator machinery

We can supply turn key project of 50-1000T/D flour milling machine, with excellent

quality, competitive price and best after-sales service.

1. Roller mills manufactured precisely and controlled by manual or pneumatic mode.

It can make better grinding effect compared with other ordinary mills.

2. Complete set of flour mill adopt various configuration modes for different choices.

There are streamlined design, reasonable layout, and good performance. It can be

installed on steel structure or in building.

3. The flour mill is with advanced technical process and flexible adjustment. It can

produce grade flour and special flour.

4. Perfect after-sales service is also supplied for all the machines.

5. We arrange engineers to help install the machine, which can ensure the machine operate efficiently.

The process of flour milling plant/machine (from wheat to milled into wheat flour)

usually consist of the following:

1. wheat storage (silos, or warehouse) ----------

2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc) -----------

3. dampening (dampener, conditioning silos, etc) ----------

4. milling system (roller mill, plansifter, purifier, impact detacher, etc.) ----------

5. Flour pressure and blending system (if need) ----------

6. flour packing and stacking.

SILOS

We store wheat in silos. There are temperature detectors inside of silos. If the temperature

inside is very high, the blower can blow air into silos to reduce the temperature to protect

the grains.We have professional engineer guide and design.

ROLLER MILL

Depending on a pair of grinding rollers,which have different peeds and rotate oppositely,

wheat endosperm is peeled from bran coat and rolled into flour via squeezing,cutting ,pee

ling and scraping.

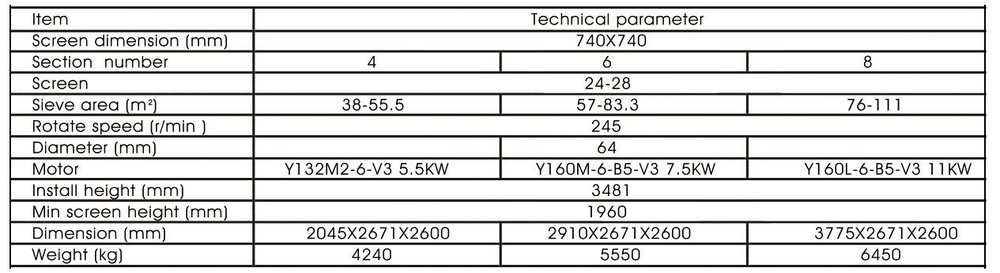

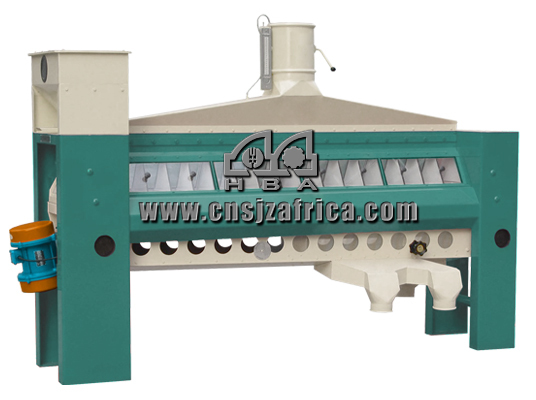

PLANSIFTER

Plansifter is mainly used for grading and inspecting of stocks from various systerms in

flour grinding.

CORN BRAKER

It is degerming equipment; it possesses the effects of "scouring,scratching,grinding and sifting".Besides the three functions of peeling,crushing and degerming,it also has outstandi

ng feature-large capacity.It adopts octagonal rotors and low rotation speed,which is helpful

for maize/corn degerming,peeling and crushing;it has eight rows of pushing plates with adj

ustable gaps to adjust the pushing speed.

CORN GERM SELECTOR

By using the specific gravity separation principle of vibration and air suction,the machine separates maize/corn bran,germ and endosperm.It is a key machine in the processing of

high precision (low fat)maize /corn products.

CLEANING SYSTEM

There are many kinds of cleaning machines. They can be used to remove stones, seed of grass, ropes, clods, straws etc to keep flour clean.

DAMPENING SYSTEM

Before being milled, the wheat should be dampened. That will help the milling. The bran will be easily separated from endosperm without damage.

MILLING SYSTEM

Roller mills break the material.

Plansifter separates the suitable size flour.

Purifier will extract the pure flour, semolina, etc.

China

China