Core Filling Snack Extruder

Description of core filling snack food

Core filling snack food can take chocolate, cheese and cream as stuffing materials,which can be mixed with yoik, milk powder and gingili sauce.We can feed the stuffing into extrusion food just before it is extruded from extruder by cre filler.this kind of core-filling food tastes crispy and delicious,such as core-filling pillow, tube and wafer.Core filling snacks food machine can use corn, rice and other grain as main materials.

Description of Core Filling Snack Extruder

1. Core Filling Snack Extruder can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape.

2.Different shapes of snacks can be produced such as Round, triangle, square, stars, flower, etc

3. Core Filling Snack Extruder is from feeding, extruding, core filling, shaping ,cutting , oil spraying to finished products are done once time automatically.

4.This extruder can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.

5.The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

6.The forced lubrication system, by guaranteed equipment transmission longer life.

7.Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

8.It also can be designed according to customer requirement.

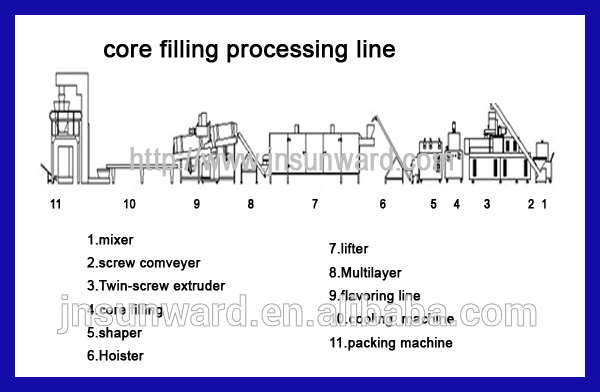

Flow chart:

Raw materials mixing----------Conveying----------Extrusion---------Core Filling---------Shaping and Cutting--------Hoisting---------Drying-----------Flavoring.

All Equipment of Core Filling Snack Extruder

Details of Core Filling Snack Extruder's host

1.The details of the host-twin screw extruder

2.The details of the eletric control cabinet

Technical Parameters of Automatic core filling snack food machine

Model | Installed power | Real power | Output | Dimension |

TSE65 | 81.5kw | 53kw | 100-150kg/h | 21000x1200x2200mm |

TSE70 | 115kw | 76kw | 200-240kg/h | 23000x1500x2200mm |

TSE85 | 181kw | 117kw | 300-500kg/h | 28000x3500x4300mm |

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing

can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service:

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

China

China