High yield fructose syrup processing plant professional fructose syrup production line

For High yield fructose syrup processing plant professional fructose syrup production line, it is enviroment friendly, no pollution. We apply dry method to transfer corn and rice flour into syrup. Since 1988, we begin to do research. We can produce high quality syrup products.

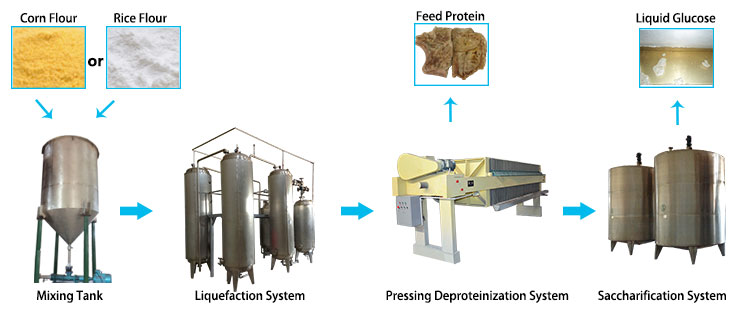

Mixing and saccharification system

1-a). The function of mixing tank is to get right density of the slurry, the water is very important at this time. Normally we use warm water, the temperature is about 50-60 degrees. And add amylase and PH reagent with mixing.

1-b). For liquefaction system,the temperature is very important. If temperature is too high the flour will be cooked. When the materials go into the first liquid ejector, the temperature should be 120 degrees. Then goes into pressure tank, and flow into four laminar flow tanks, finally go out from maintaining tank. This tank connected with another liquid ejector. The temperature should be 108 degrees. The time between these procession is about 90 minutes. Then the materials go into transfer tank. The mainly usages of transfer tank are:

1. if the liquefaction is not finished, we can put all the materials into liquefaction system again.

2. to make preparation of pressing.

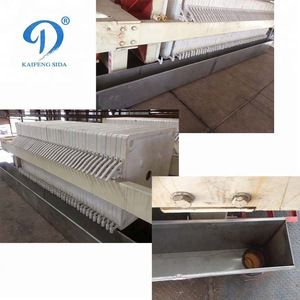

1-c). Press filter is the parts to take all the protein out, at 70 - 80 degree Celsius will be very efficiency.

We use air compressor to increase the pressure. When we finished the pressing, we can use water cannon to clean these machine.

1-d) After the pressing, the materials go into saccharification tank. But before entering, we will use a heat-exchanger to make the temperature under 60 degrees. Then we put fructose enzymes and PH reagent into these tanks. And after their chemical reaction, we will put the temperature above 90 degrees to kill fructose enzymes.

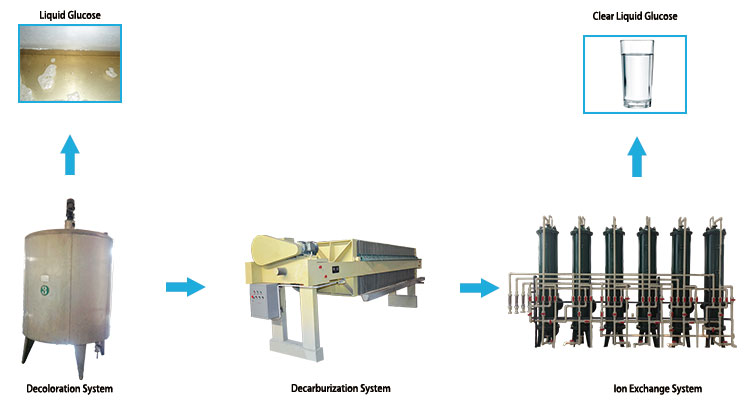

Decoloration and purifying system

2-a). The decoloration main function is to attract color, this step will be effect to the final product level, about 90% of colour will be attract inside the activated carbon, this parts the temperature is very important too. The press machines are used to remove the activated carbon.

2-b). For inox exchange system, we can use a heat-exchanger to make the temperature about 40 degrees.

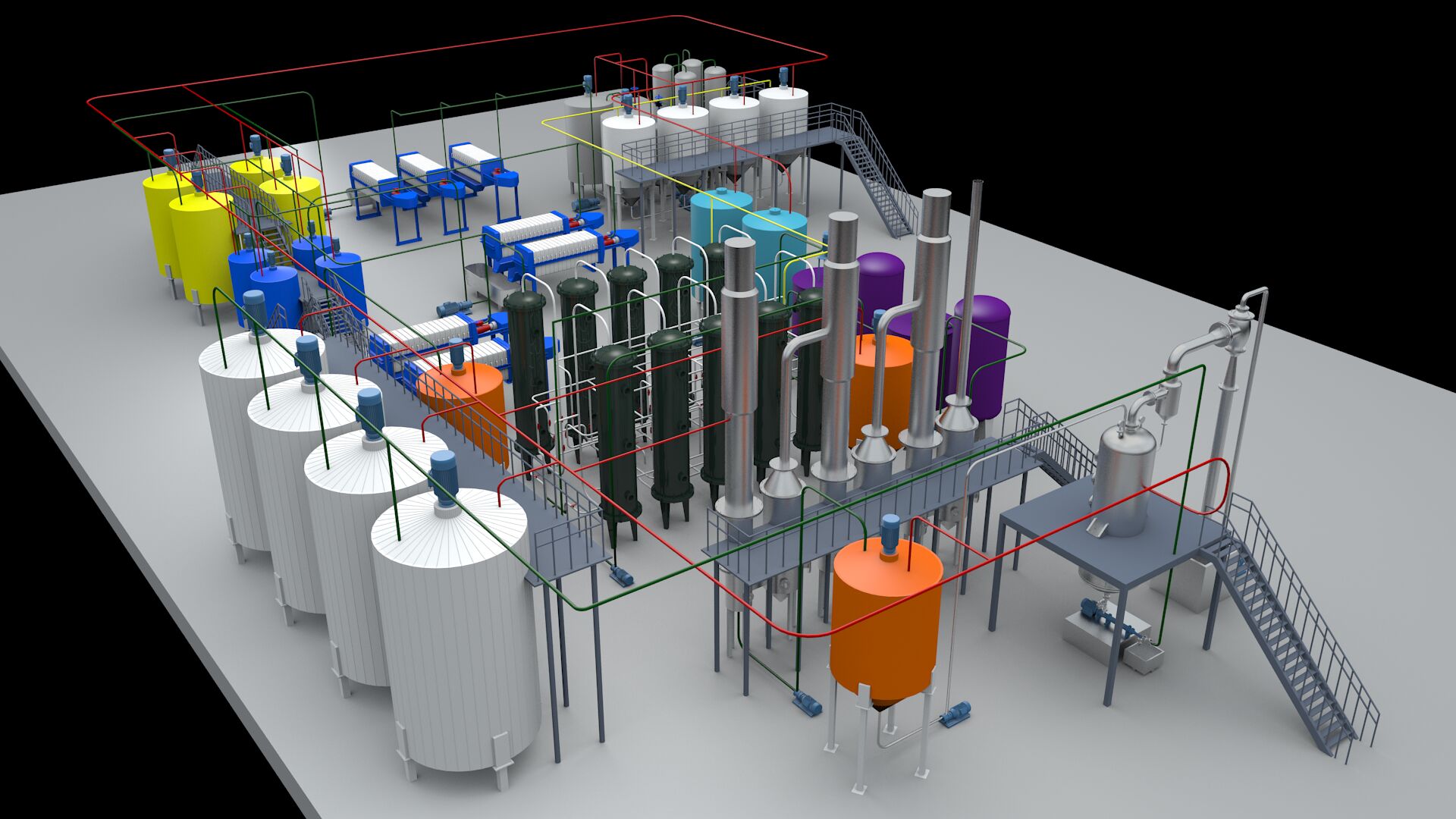

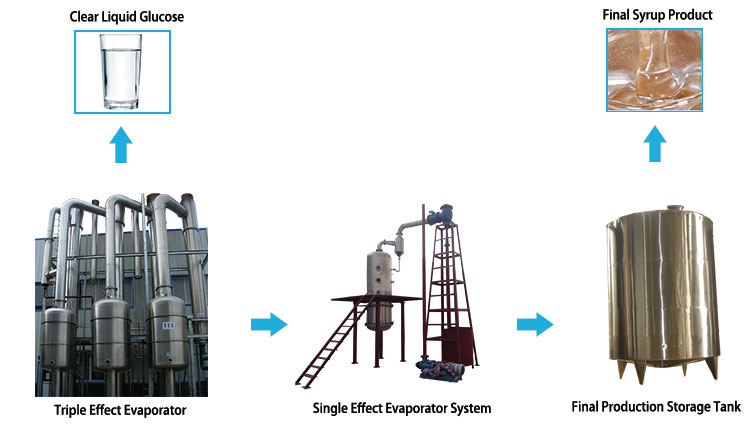

Concentrating and storage system

3-a). Triple effect evaporator mainly used to concentrate the fructose density according to the demands; Single effect evaporator can improve the high density.

3-b). This is the last step, from this part customer can got final product, how much density you need, what color you need; Final storage tank make sure all the fructose syrup can be store properly, because the fructose will be thick on the pipe when the density is high like 84%, the fructose syrup can not pump out if the storage not properly. So the tank have constant temperature to make sure it can pump out in anytime. And normally only the temperature is under 60 degree, the color of syrup won't change. In summer, the temperature is okay. And in winter we just need to open the steam gate, and add some steam.

Our factory workers will pack all the machines by crane and forklift. All the machines will be shipped by the container.

Project installation: we have professional electrical and mechanical project installation team. The display of the equipment is neat, reasonable, beautiful, generous, and easy maintenance.

Our company is professional in manufacturing of starch production equipment and glucose / maltose / fructose production equipment. With fixed assets of US $6,000,000.00, covering an area of 33,335 square meters, with an annual production value of US$8,000,000.00.

We are intiative of using raw grains (corn / rice / broken rice) to produce gucose directly and deeper conversion of fructose syrup & sorbbitol technology. We own 15 national invention patents, with customers all over the world, such as Russia, india, Cambodia, Indonesia, South Africa, Uzbekistan, Syria, bulgaria, Algeria, Pakistan, Bangladesh, Kazakhstan, Nigeria, Vietnam, Uruguay, Cameroon, etc.

Clients Visiting

And we have attended many exhibitions both in demostic market and foreign market.

1. Q: How do you prove that you are manufacturer?

A: Patents No. can be offered, so you can verification on net.

2. Q: What is the use of the machine?

A: This machine is used for making tapioca starch.

3. Q: What is your quality inspection for tapioca machine?

A: We inspection from raw material to final processing equipment, our welders gets European welder card.

4. Q: What is your after sales services?

A: 15 days installing and training on buyer's factory, 12 months gurantee time for the cassava starch processing equipment.

5. Q: How can I ask more information about cassava starch processing equipment?

A: Pls feel free to contact with us if you have any question. All your mail will be answered in 12hours.

| Jenny

WhatsApp: +86 131 9376 8681

Add: No. 18 Weiliu Road of Huanglong Park, Economic Development District, Kaifeng, Henan, 475000, China. |

China

China